Description

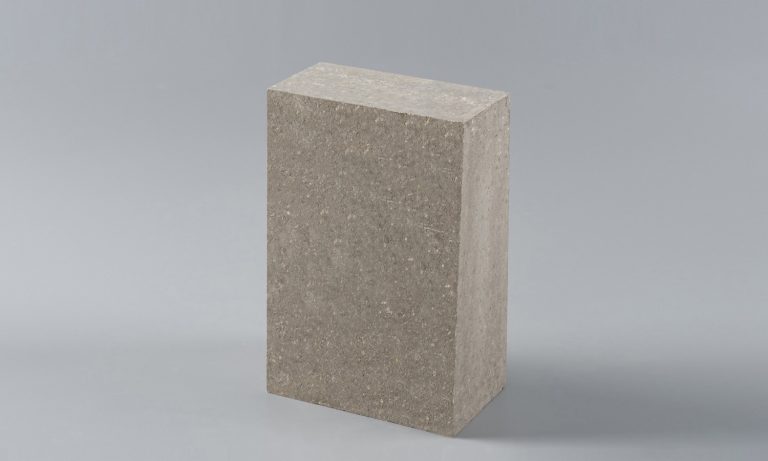

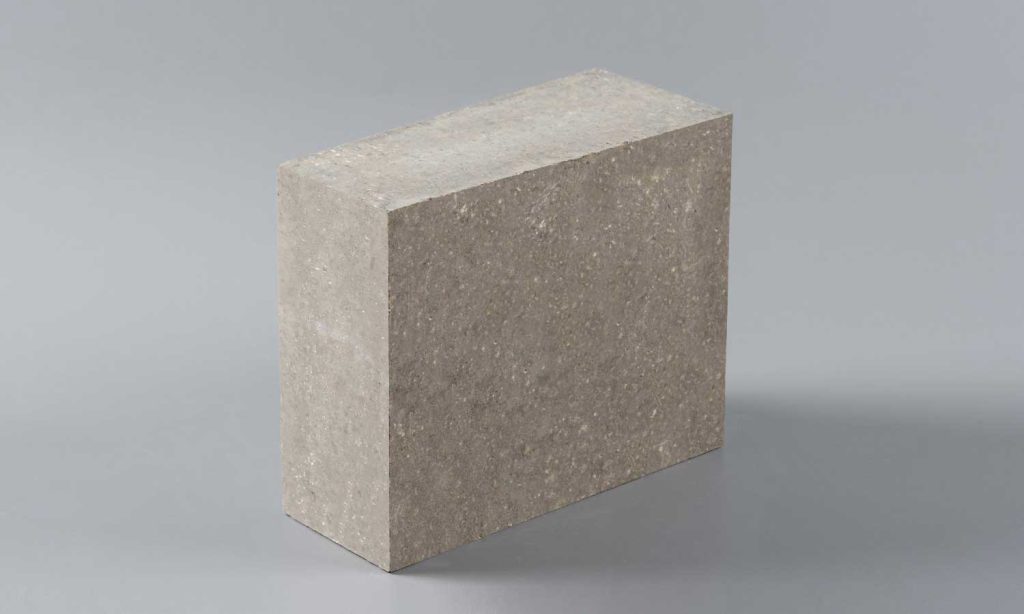

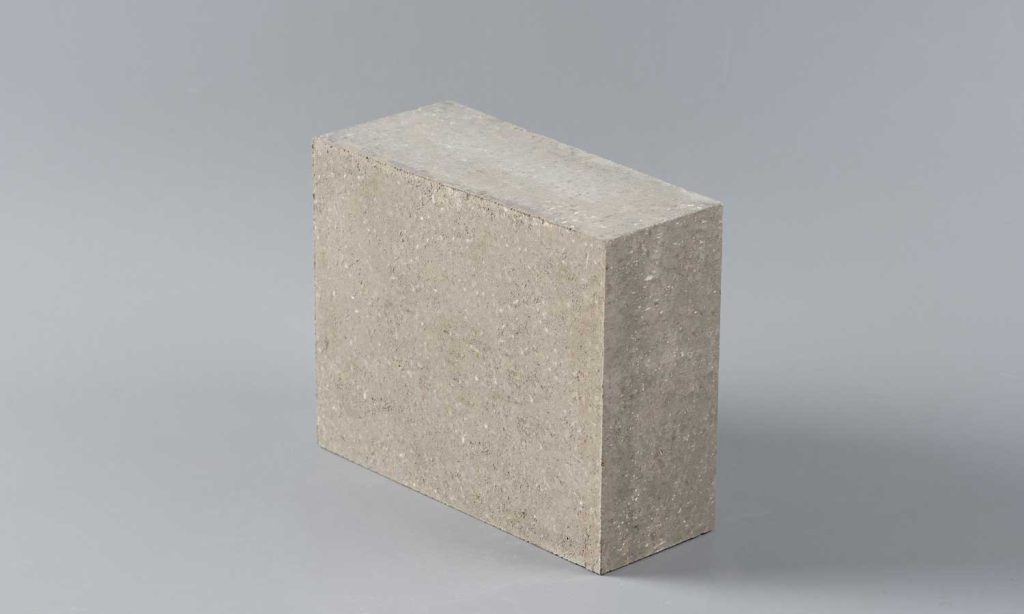

Phosphate bonded high alumina brick is a kind of refractory brick made primarily from high alumina bauxite clinker, corundum, and mullite, using a phosphate chemical bonding process. These bricks feature high compressive strength, low porosity, excellent thermal shock resistance, good wear resistance, and strong anti-spalling performance.

Related Products:

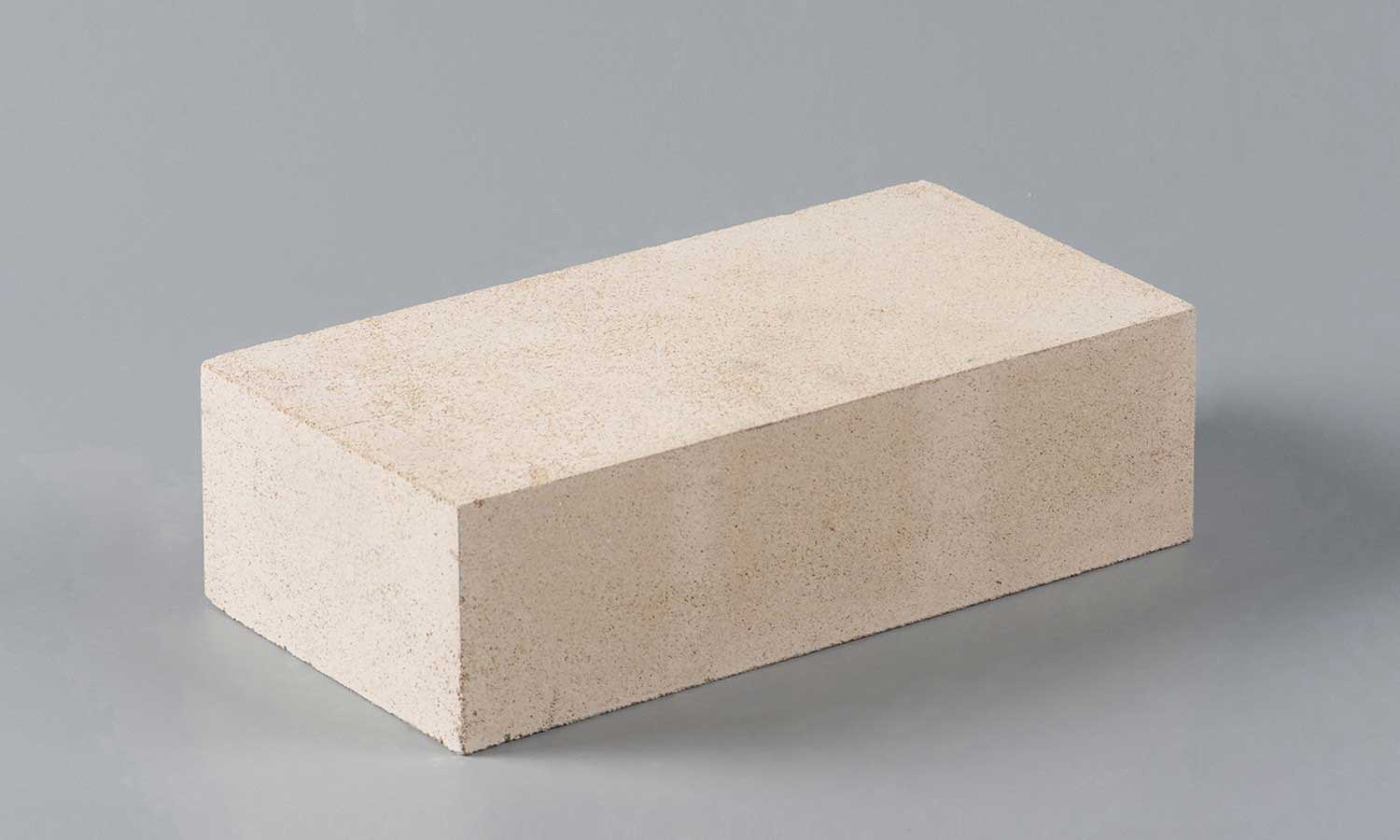

High Alumina Brick: normal neutral refractory brick, with an alumina content of 48% to 80%, more>

Magnesia Alumina Spinel Brick: alkaline refractory brick, good resistance to alkaline slag, withstand 2000℃, more>

Phosphate Boned Corundum Castable: high refractoriness, corrosion resistance, high strength, strong wear resistance, more>

Specifications

| Item | Grade | |||||

| PA-80 | PA-75 | PA-70 | PA-65 | PA-60 | PA-55 | |

| Al2O3 / (%) | 80 | 75 | 70 | 65 | 60 | 55 |

| Bulk Density / (g/cm³) ≥ | 3 | 2.9 | 2.8 | 2.7 | 2.6 | 2.5 |

| Open Porosity / (%) ≤ | 12 | 14 | 15 | 16 | 17 | 18 |

| CCS / MPa ≥ | 150 | 120 | 100 | 90 | 80 | 70 |

| λ 1000℃ [W/(m·K)] | / | 2 | 2 | 2 | 2 | 2 |

| R.U.L (0.2 MPa T0.6) / ℃ ≥ | 1550 | 1500 | 1480 | 1450 | 1400 | 1350 |

| TSR (1100 ℃~ cold water) ≥ | 10 | 10 | 10 | 10 | 10 | 10 |

| Abrasion Resistance RT / cm3 | 5 | 5 | 5 | 5 | 5 | 5 |

Advantages of Phosphate Bonded Alumina Bricks

- High mechanical strength and excellent wear resistance

- Superior thermal performance (high R.U.L, low creep, thermal shock stability)

- Outstanding corrosion and anti-stripping resistance

- Extended service life

Product Size

| Type | Brick Size | KilnDiameter | |||

| a | b | h | l | D1 | |

| mm | mm | mm | mm | mm | |

| HX-25 | 121 | 97 | 250 | 200 | 2500 |

| HX-30A | 121 | 99 | 270 | 200 | 3000 |

| HX-30B | 108 | 90 | 250 | 200 | 3000 |

| HX-35A | 123 | 104 | 270 | 200 | 3500 |

| HX-35B | 119 | 102 | 250 | 200 | 3500 |

| HX-40D | 120 | 105 | 250 | 200 | 4000 |

| SH-40B | 226 | 200 | 230 | 98 | 4000 |

Applications

Phosphate bonded high alumina bricks are widely used in high-temperature industrial applications, including cement rotary kilns (transition zone, preheat zone, and cooler lining), lime kilns, and rotary kilns for metallurgical solid waste and magnesium production. They are also suitable for steel and non-ferrous metal smelting, as well as ceramics, glass, petroleum, chemical, and power industries.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.