Description

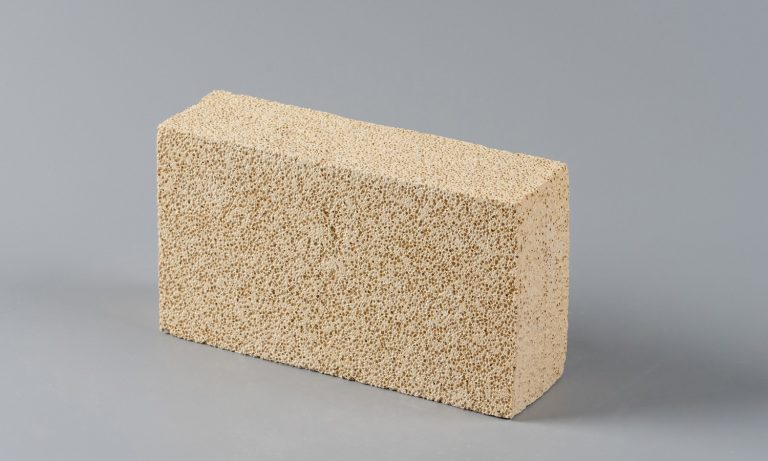

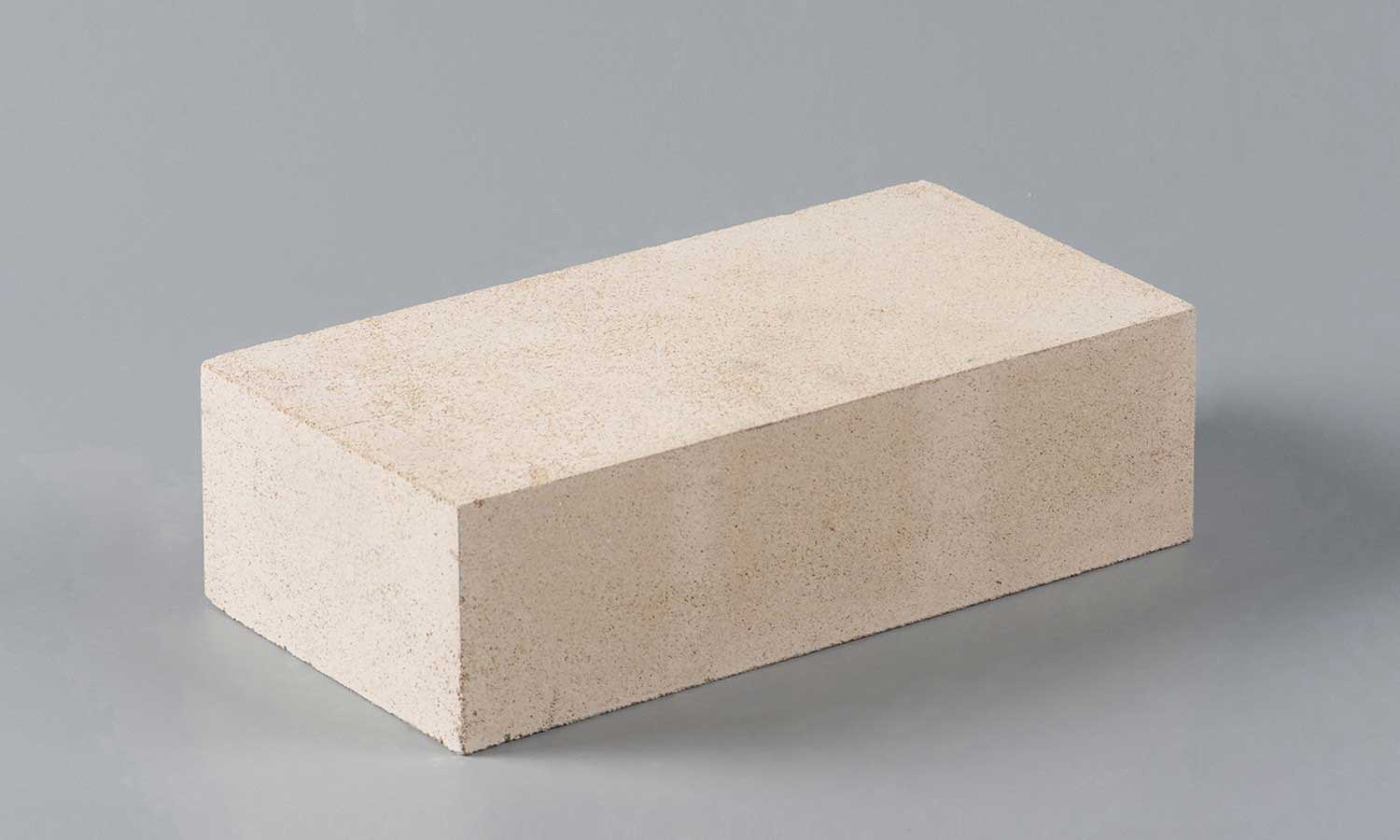

Poly-light high-alumina brick is a new type of lightweight insulation material made from high-alumina bauxite as the main raw material, with a certain amount of combustible substances or foaming agents added, and then processed through high-temperature sintering. Poly-light high-alumina bricks have the advantages of low density, high mechanical strength, excellent fire resistance, strong slag resistance, and thermal shock stability. As a result, they are widely used in high-temperature fields such as furnaces, metallurgy,etc. They are generally used for furnaces lining and insulation layers, as well as areas that are not subject to intense high-temperature molten material erosion and scouring. When in direct contact with flames, the surface contact temperature should not exceed 1350°C.

Specifications

| Item | Grade | |||||

| JLG-1.3L | JLG-1.0L | JLG-0.8L | JLG-0.7L | JLG-0.6L | JLG-0.5L | |

| ω(Al₂O₃) / % ≥ | 72 | 60 | 55 | 50 | 50 | 48 |

| ω(Fe₂O₃) / % ≤ | 1.5 | |||||

| Bulk Density / (g/cm³) ≤ | 1.3 | 1.0 | 0.8 | 0.7 | 0.6 | 0.5 |

| CCS / MPa ≥ | 5 | 3 | 2.5 | 2.0 | 1.5 | 1.2 |

| min4.5 | min2.5 | min2.0 | min1.5 | min1.2 | min1.0 | |

| HPLC / % (T/℃×12 h) | 1700℃ -1.0~0.5 | 1600℃ -1.0~0.5 | 1500℃ -1.0~0.5 | 1400℃ -1.0~0.5 | 1350℃ -2.0~1.0 | 1350℃ -2.0~1.0 |

| λ W/m·k / ≤ (350±25)℃ | 0.6 | 0.50 | 0.35 | 0.30 | 0.25 | 0.20 |

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

Applications

Poly-light high-alumina bricks can be used as insulation layers in industrial kilns such as metal smelting furnaces, cement kilns, and ceramic kilns. They can help reduce the weight of the furnace, shorten kiln firing times, minimize heat diffusion and maintain uniform furnace temperature.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.