Description

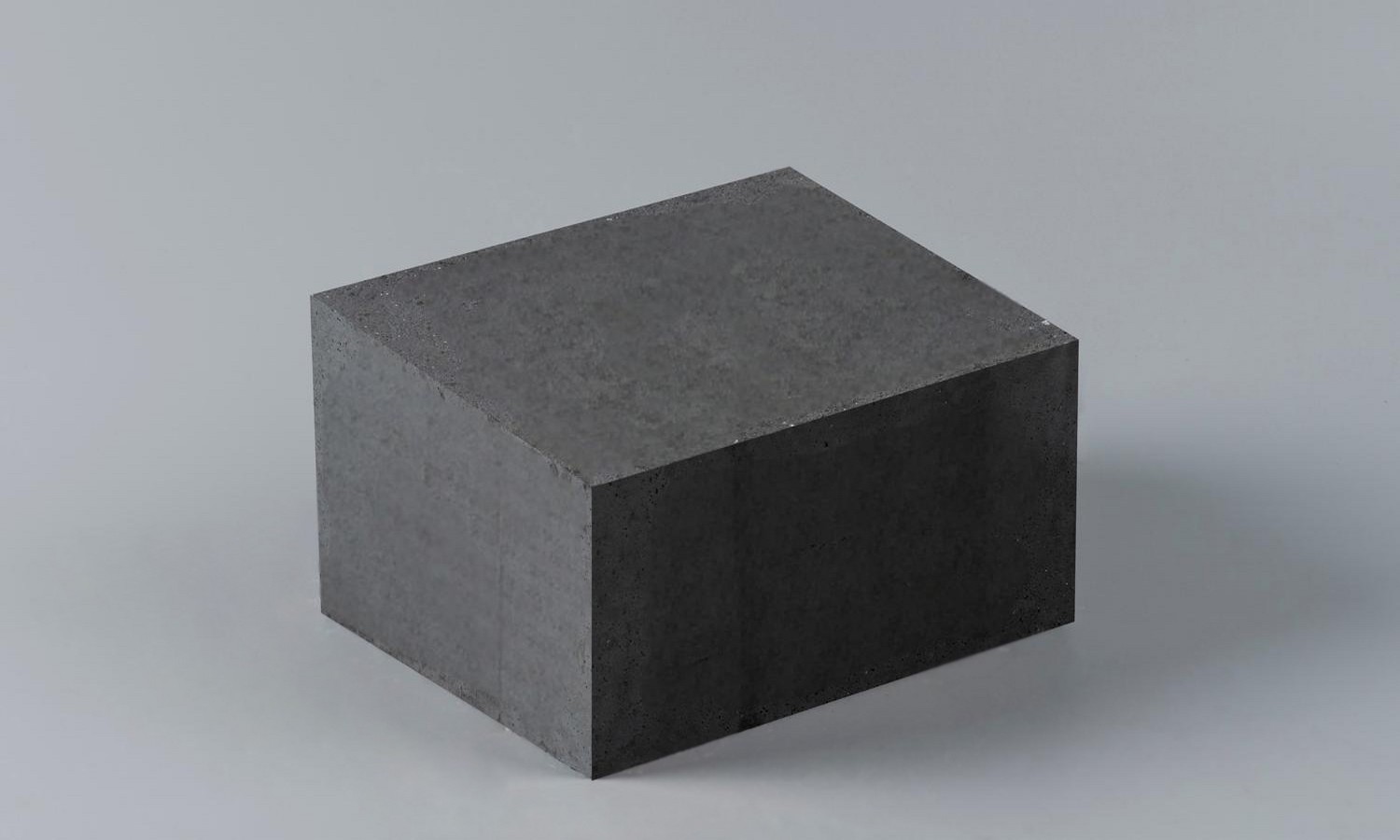

Alumina bubble brick is made primarily from alumina hollow balls and alumina powder, combined with other binders and fired at a high temperature. It is a type of ultra-high temperature energy-saving thermal insulation material. The characteristics of these bricks include excellent thermal insulation properties (low thermal conductivity and high thermal resistance), high fire resistance, chemical stability, good thermal stability, and a certain degree of mechanical strength.

Related Products

Poly lightweight alumina brick: low density, strong slag resistance, thermal shock stability, working temp≤1350℃, more>

Mullite insulation brick: low thermal conductivity, low thermal expansion, excellent thermal shock resistance, more>

Nano insulation board: a micro-porous structure of high-efficiency thermal insulation board, more>

Alumina Bubble Brick Advantages

- Long-term working in 1800°C environment

- Low bulk density

- Low thermal conductivity (0.2~0.5 W/(m·K))

- High strength

- Good thermal shock resistance

- Chemical resistance

Specifications

| Item | LQZ-99 -1.4 | LQZ-99 -1.6 | LQZ-99 -1.8 | LQZ-95 -1.4 | LQZ-95 -1.6 | LQZ-95 -1.8 | LQZ-90 -1.4 | LQZ-90 -1.6 | LQZ-90 -1.8 |

| ω(Al₂O₃) / % ≥ | 99 | 95 | 90 | ||||||

| ω(SiO₂) / % ≤ | 0.3 | – | – | ||||||

| ω(Fe₂O₃) / % ≤ | 0.2 | 0.2 | 0.2 | ||||||

| Bulk density / (g/cm³) | 1.3~1.5 | 1.5~1.7 | 1.7~1.9 | 1.3~1.5 | 1.5~1.7 | 1.7~1.9 | 1.3~1.5 | 1.5~1.7 | 1.7~1.9 |

| CCS / MPa ≥ | 6 | 10 | 12 | 8 | 12 | 16 | 10 | 14 | 18 |

| λ [W/m·k] (350±25℃) ≤ | 0.9 | 1.1 | 1.2 | 0.9 | 1.1 | 1.2 | 0.9 | 1.1 | 1.2 |

| HPLC (1600℃×3h) / % | -0.3~+0.3 | -0.3~+0.3 | -0.3~+0.3 | ||||||

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

Alumina Bubble Brick Applications

- Insulation and working layers in the blast furnace hot blast stoves, heating furnaces, soaking pits, etc.

- Insulation layer of the tank wall, breast wall, and other sections of glass melting furnaces.

- Linings and insulation layers in the kilns of tunnel kilns, shuttle kilns, roller kilns, and other glass furnaces.

- Thermal insulation in the furnace chambers, flues, air preheaters, and other parts of boilers in thermal power plants.

- Insulation layers in furnaces for non-ferrous metal smelting.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.