The cement rotary kiln is one of the most critical pieces of equipment in cement production. It is primarily used for calcining raw meal, which has been preheated and partially decomposed, into clinker. It is the core process in cement manufacturing.The cement rotary kiln is generally divided into different zones, including the preheating zone, decomposition zone, transition zone, and Clinkering zone.

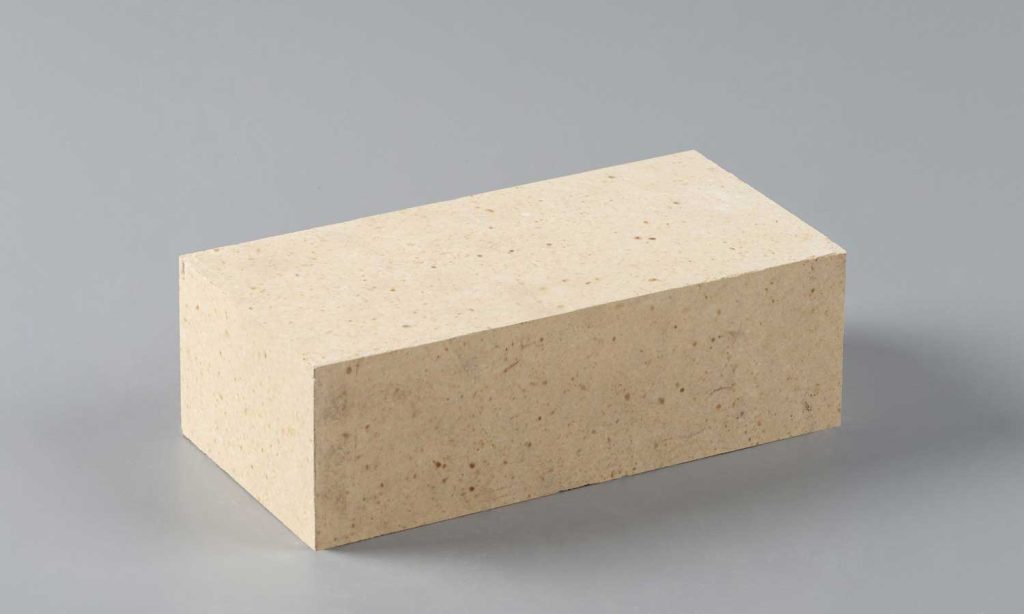

The temperature inside the rotary kiln is very high, reaching up to 1450°C, especially in the Clinkering zone. This requires refractory materials that can withstand high temperatures, resist erosion, wear-resistant. Magnesia-chrome bricks were previously used in this area, but now magnesia-spinel bricks are commonly employed.

Our Services

- Cement Rotary Kiln Design

- Refractory Material Configuration for Different Zones

- Integrated Refractory Material Construction

- Analysis of Refractory Material Usage Issues

- Full-Process Technical Follow-up Services

Related products