High-Temperature and Slag-Resistant Refractories for Smelting Stability

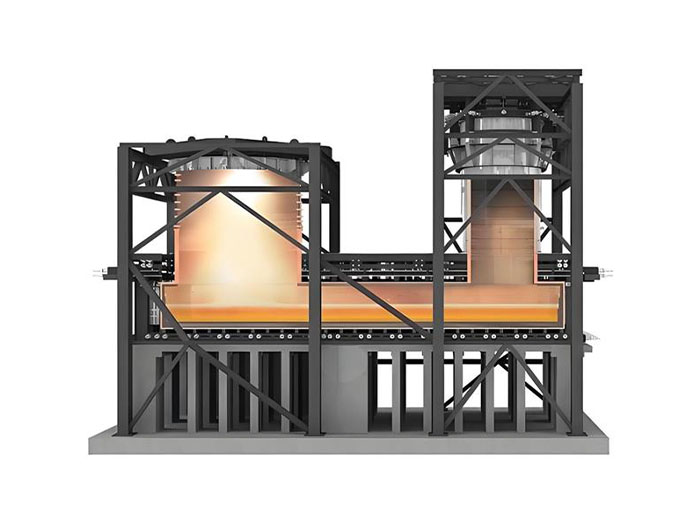

Smelting processes for aluminum, copper, nickel, and zinc operate under extreme thermal and chemical conditions, requiring refractories with superior oxidation resistance, slag corrosion resistance, and thermal shock resistance. Utilizing advanced grain size distribution and composite reinforcement technology, we provide high-purity corundum bricks, magnesia-chrome bricks, and erosion-resistant castables to ensure furnace stability, minimize metal contamination, and enhance refining purity.

Key Applications:

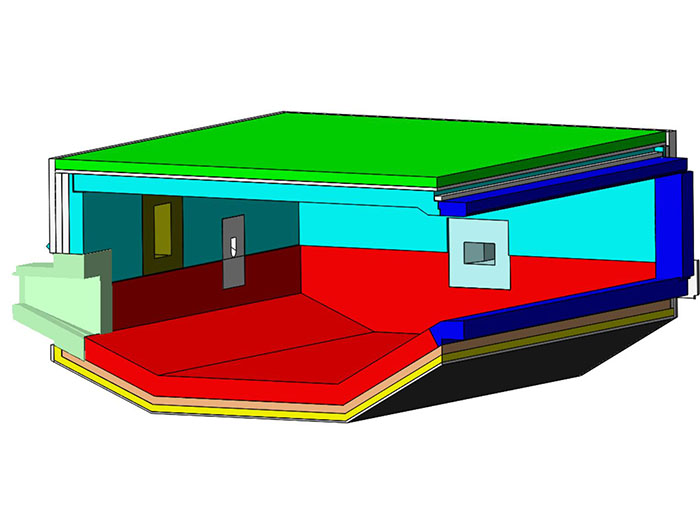

Flash smelting furnaces, reverberatory furnaces, electrolytic cells, aluminum melting furnaces, refining furnaces

Recommended Products:

High-purity corundum bricks, magnesia-chrome bricks, erosion-resistant castables, anti-penetration refractory coatings