Tailored Refractory Solutions for Optimized Furnace Lining Management

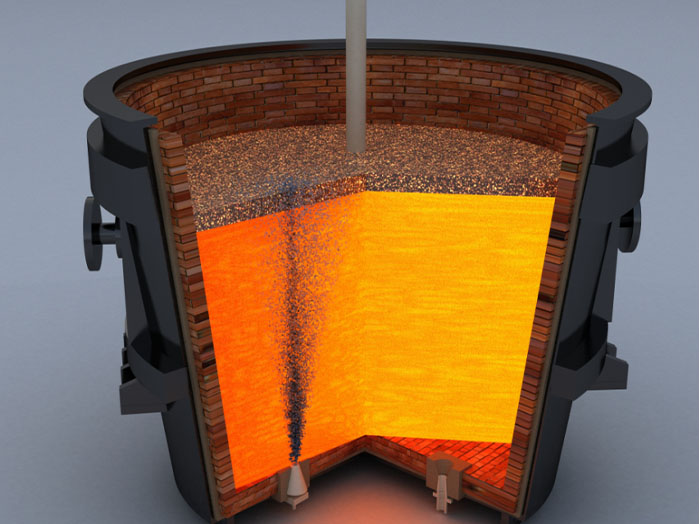

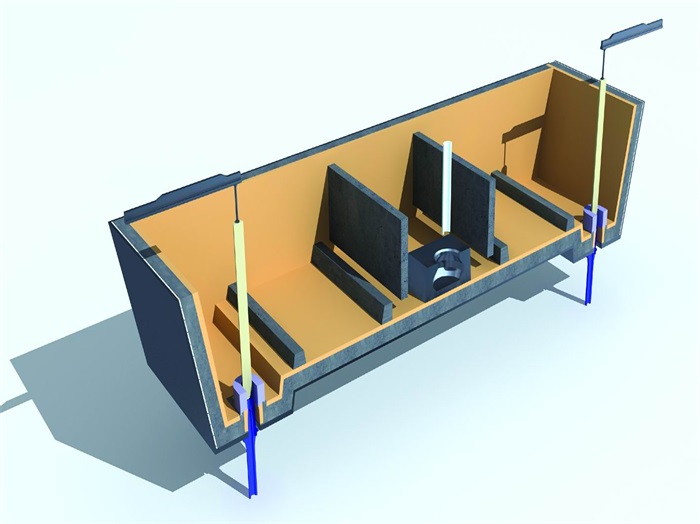

Steel production involves multiple high-temperature processes, including blast furnaces, converters, electric arc furnaces (EAF), ladles, and continuous casting systems. Our customized refractory solutions include high-performance magnesia-carbon bricks, alumina-silicon carbide castables, and low-carbon refractories, enhancing slag resistance, minimizing refractory wear, and improving operational efficiency.

Key Applications:

Blast furnace hearth, bosh, and shaft; converter and EAF linings; ladles; tundishes in continuous casting

Recommended Products:

High-purity magnesia-carbon bricks, alumina-silicon carbide castables, eco-friendly carbon-free refractories, high-wear-resistant corundum castables