High-Wear-Resistant Refractories for Energy Optimization

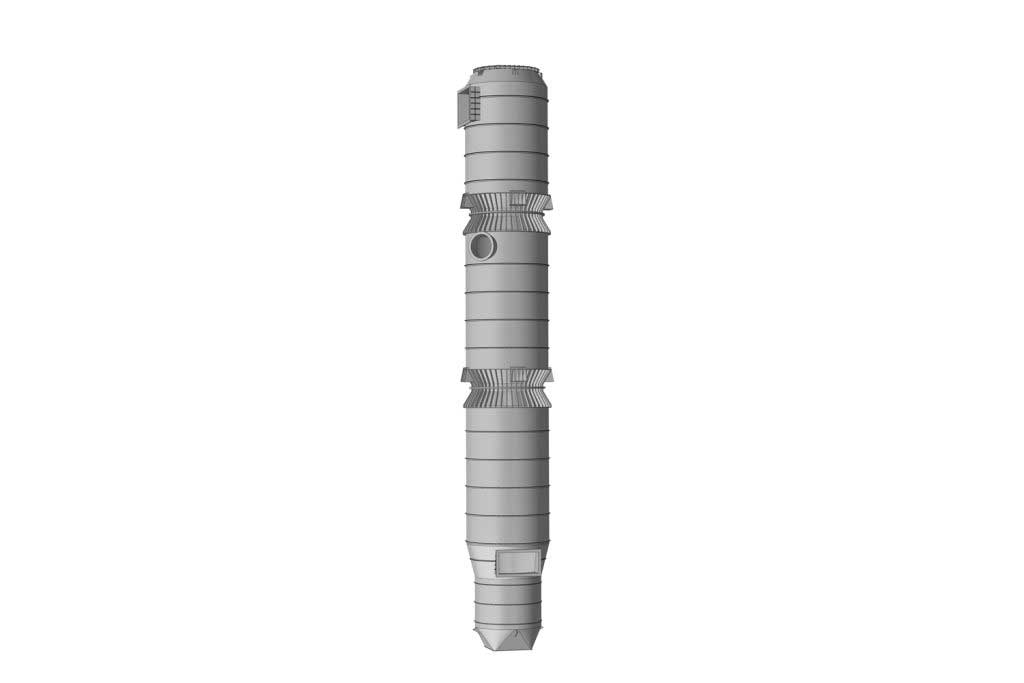

Cement rotary kilns are exposed to extreme heat, aggressive alkaline environments, and high-velocity dust erosion. Our high-performance magnesia-alumina spinel bricks, anti-spalling high-alumina bricks, and advanced wear-resistant coatings ensure optimal heat stress distribution, improve kiln operation efficiency, reduce energy consumption, and extend refractory lining lifespan.

Key Applications:

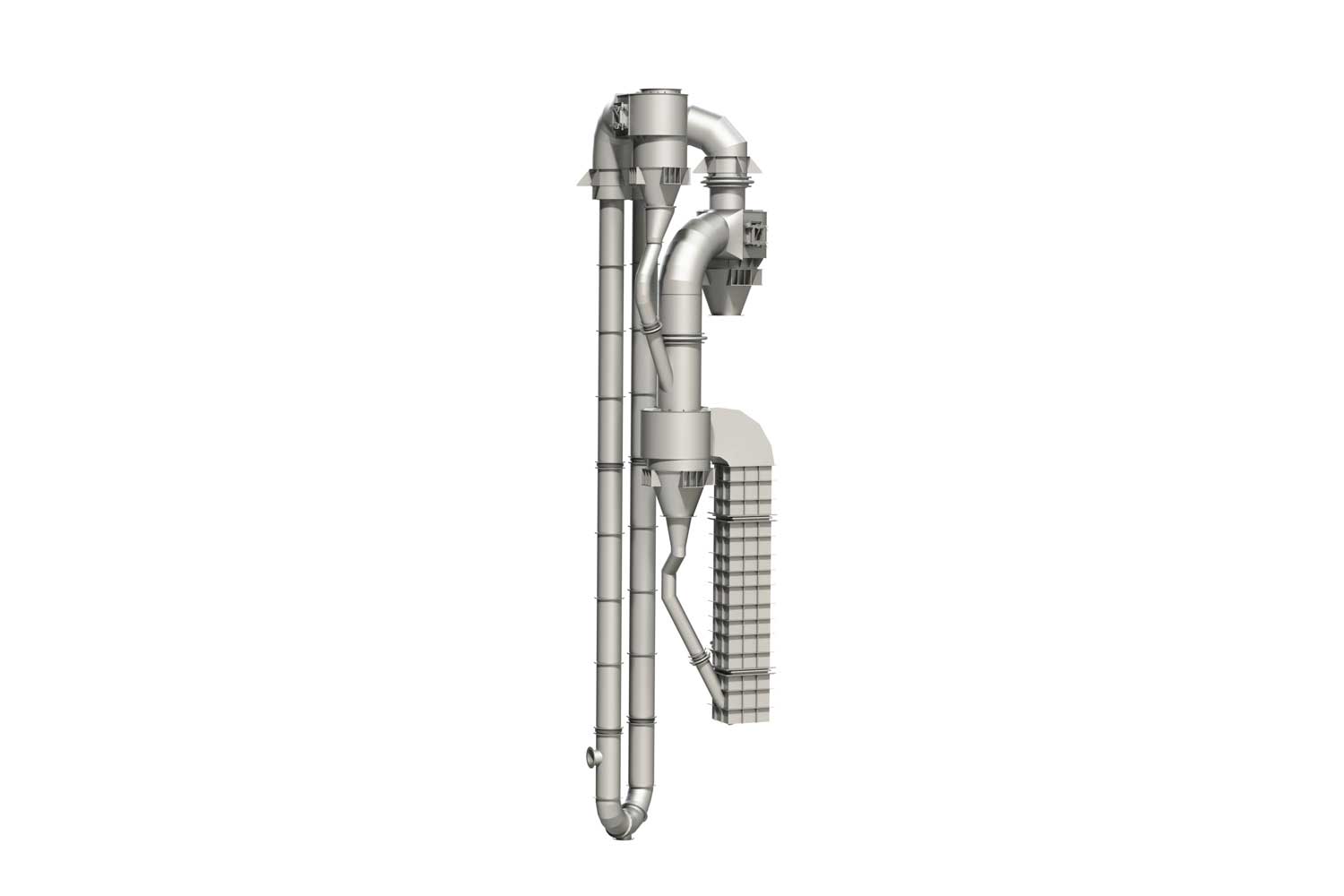

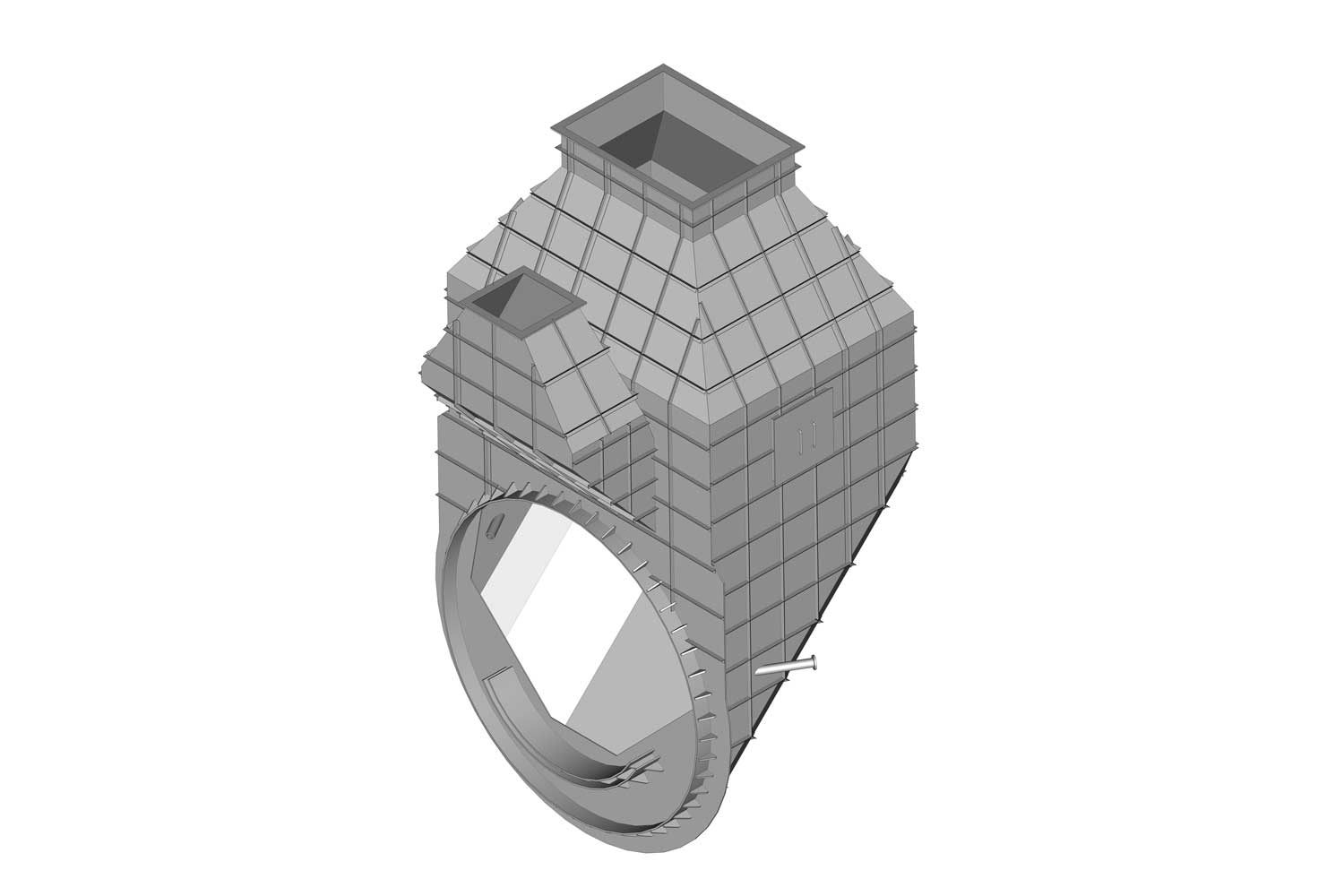

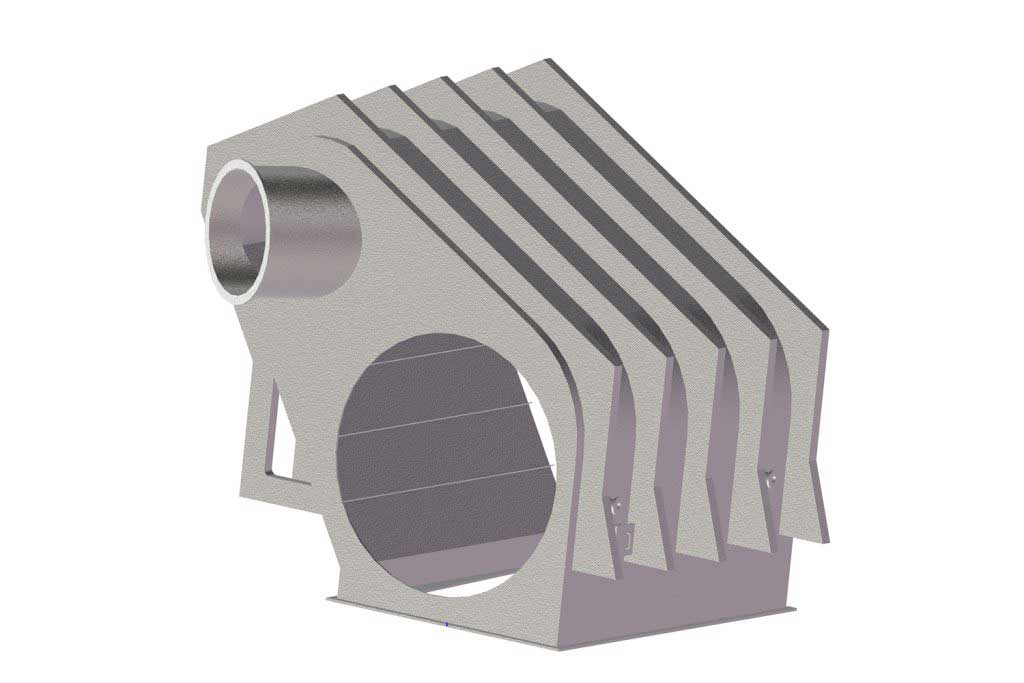

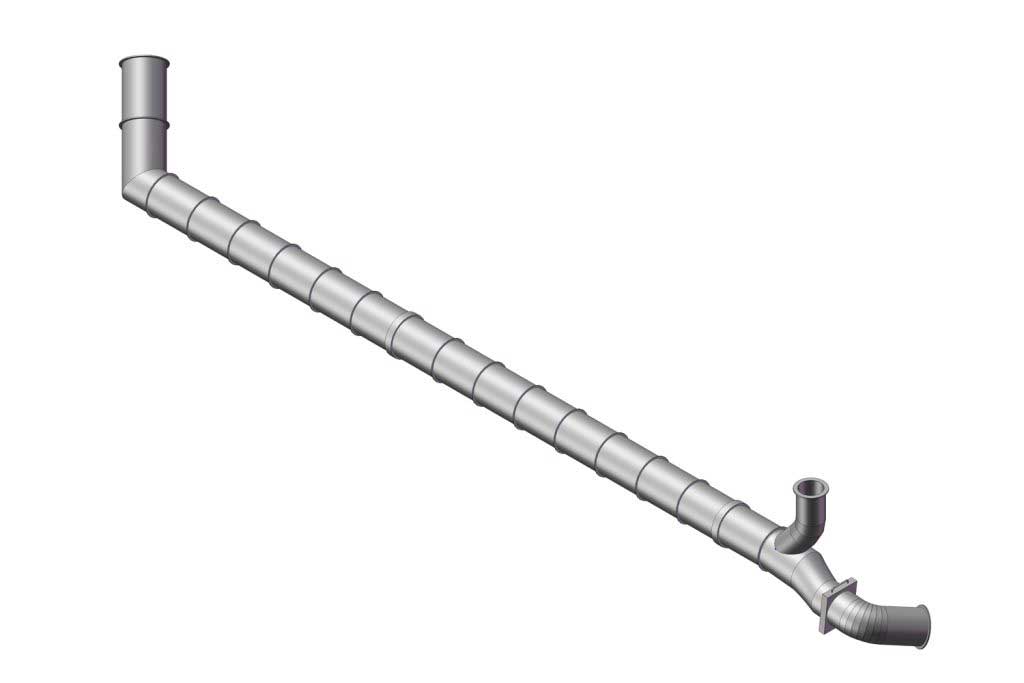

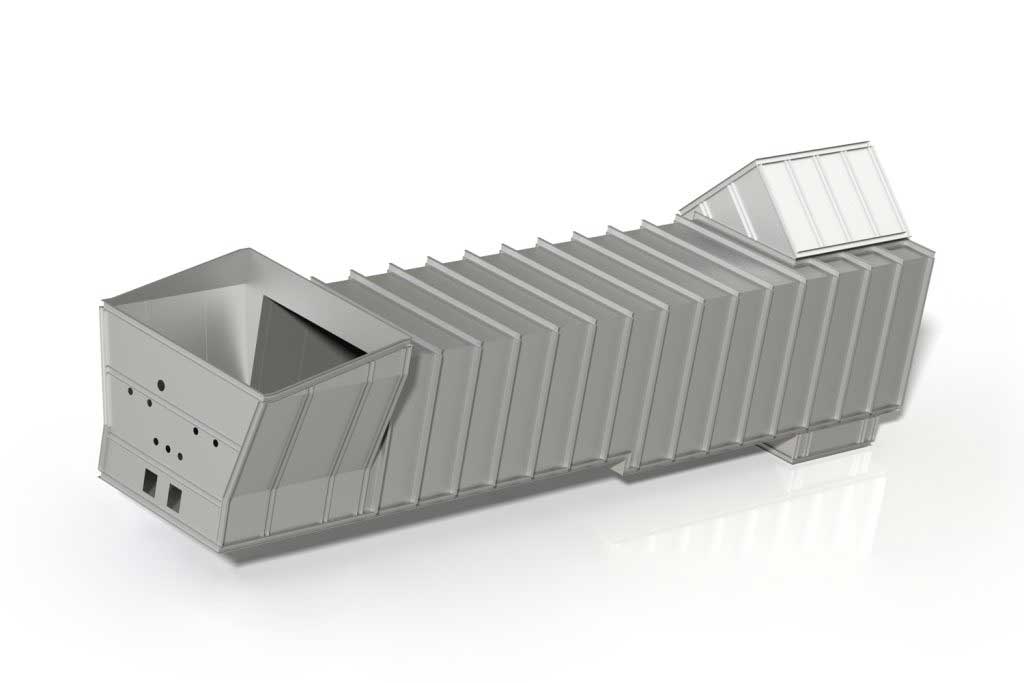

Rotary kiln burning zone, transition zone, preheater, grate cooler

Recommended Products:

Magnesia-alumina spinel bricks, high-alumina bricks, alkali- and sulfate-resistant castables, high-temperature wear-resistant coatings