Description

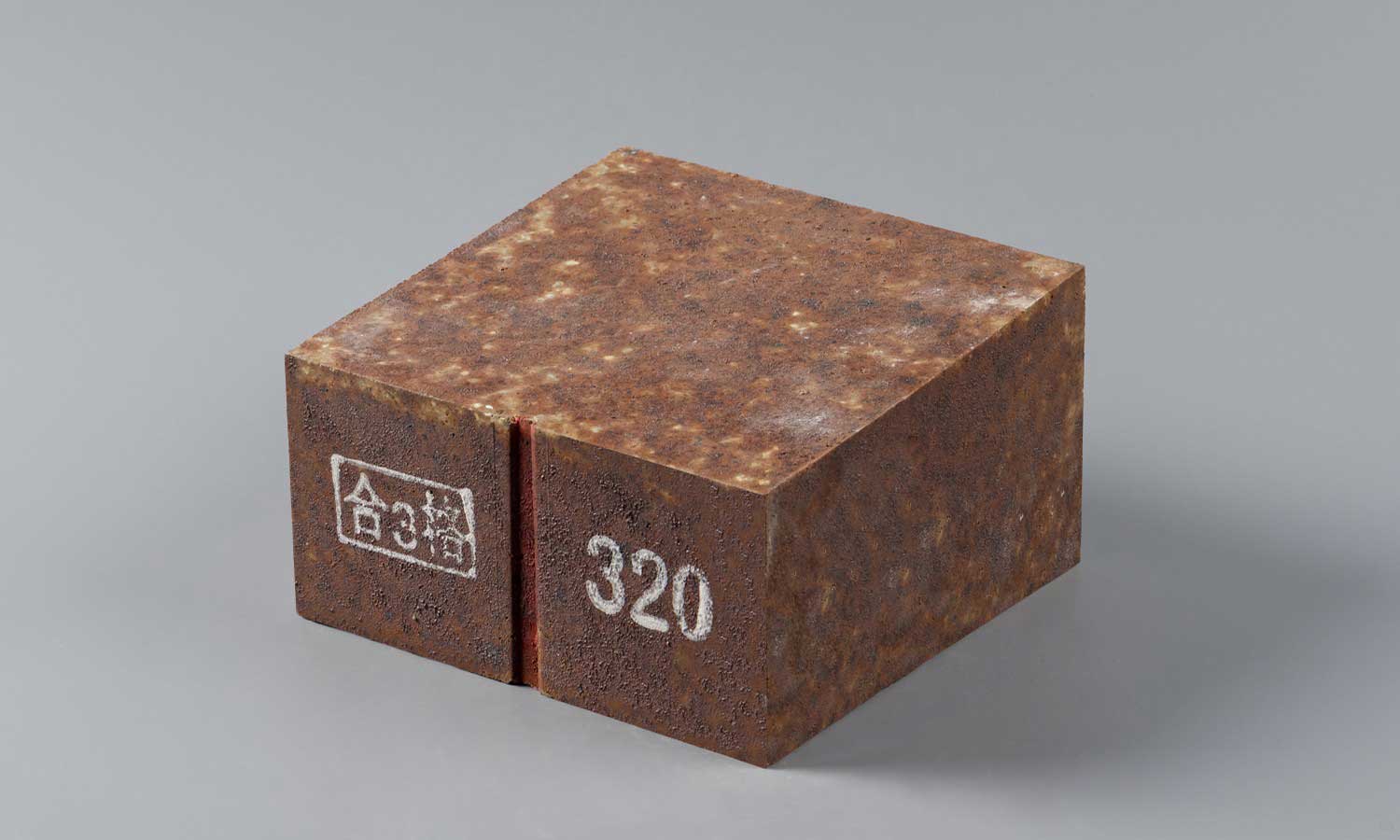

Silicon carbide carbon brick is a kind of refractory brick material made of calcined anthracite, silicon carbide and graphite as the main raw materials, which calcined at high temperature. They are mainly used for building linings and tapholes of submerged arc furnaces.

Silicon carbide carbon brick is an ideal lining material for submerged arc furnaces. It has high thermal conductivity, can dissipate heat quickly, has good high temperature strength that makes it not easy to deform, and has good oxidation resistance and thermal shock resistance that allows it to withstand complex working environments.

Specifications

| Items | Properties | |

| Density / (g/cm3) | ≥1.75 | |

| Open Porosity / % | ≤18 | |

| CCS / MPa | ≥32 | |

| ω(SiC) / % | ≥30 | |

| Alkali resistance | U or LC | |

| Oxidation / % | ≤20 | |

| λ / (W/(m ▪ k)) | RT | ≥6 |

| 600℃ | ≥8 | |

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

Applications

Silicon carbide carbon bricks are mainly used in the furnace bottom, furnace wall and furnace column of the submerged arc furnace. The SiC-C bricks on the furnace bottom can withstand the erosion and scouring of high-temperature melt and reduce heat loss. The SiC-C bricks on the furnace wall can resist high temperature and slag erosion and maintain the stability of the furnace structure. The SiC-C bricks of the furnace column can withstand high temperature and mechanical stress, ensure the efficient and stable operation of the submerged arc furnace, increase the overall service life, and reduce the maintenance frequency and cost.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.