Description

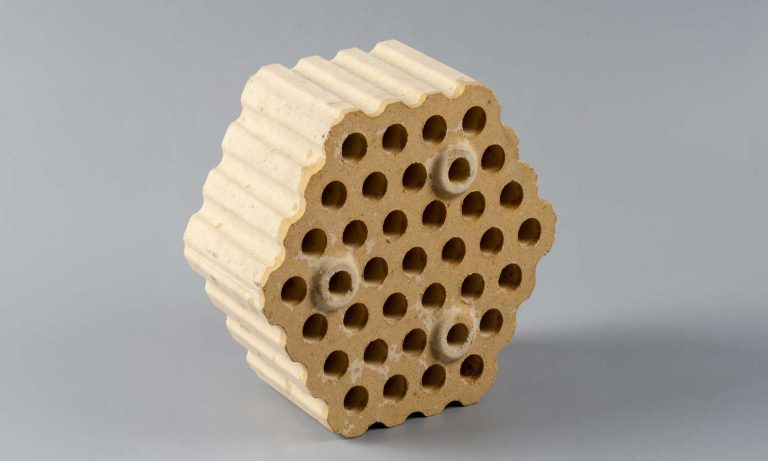

Silica brick is an acidic refractory brick, usually containing more than 93% silica, and also contains a small amount of impurities such as alumina, calcium oxide, and iron oxide.

Silica bricks are divided into four types according to their use: general silica bricks, silica bricks for glass kilns, silica bricks for coke ovens, and silica bricks for hot blast furnaces.

Fused quartz brick: low thermal expansion coefficient, good thermal shock resistance and chemical stability, more>

Fused AZS Zirconia Corundum Brick: first choice for the upper and lower structures of the melting chamber in glass furnace, more>

Specification

Specification of Normal Silica Refractory Brick

| Items | Properties |

| GZ-94 | |

| ω(SiO2) / % | ≥94 |

| ω(Fe2O3) / % | ≤1.4 |

| Open Porosity / % | ≤24 |

| Density / (g/cm3) | ≤2.35 |

| CCS / MPa | ≥30 |

| 0.2 MPa R.U.L / ℃ | ≥1 650 |

Specifications of Silica Bricks for Glass Kiln

| Items | Grades | |||

| BG – 96a | BG – 96b | BG – 95 | ||

| ω(SiO2) / % | μ0 | ≥96 | ≥96 | ≥95 |

| ω(Fe2O3) / % | μ0 | ≤0.6 | ≤0.8 | ≤1.0 |

| Melt index / % | μ0 | ≤0.5 | ≤0.7 | —— |

| Open Porosity / % | μ0 | ≤21 | ≤22 | |

| Density / (g/cm3) | μ0 | 2.34 | ||

| CCS / MPa | μ0 | ≥40 | ≥35 | ≥30 |

| Xmin | 30 | 25 | 20 | |

| 0.2 MPa R.U.L / ℃ | μ0 | ≥1680 | ≥1670 | ≥1670 |

| HPLC ( 1450℃×2h ) / % | Xmin ~ Xmax | 0 ~ 0.2 | ||

| Residual Quartz / % | μ0 | ≤3 | ||

Specifications of Silica Bricks for Coking Furnace

| Items | Properties | |||

| JG-94 | ||||

| Bottom | Lining | Other | ||

| ω(SiO2) / % | μ0 | ≥94.5 | ≥94.0 | |

| ω(Al2O3) / % | μ0 | ≤1.2 | ≤1.5 | |

| ω(Fe2O3) / % | μ0 | ≤1.2 | ≤1.5 | |

| ω(CaO) / % | μ0 | ≤3.0 | ≤3.0 | |

| ω(Na2O+K2O) / % | μ0 | ≤0.35 | ≤0.35 | |

| Open Porosity / % | μ0 | ≤22 | ≤24 | |

| CCS / MPa | μ0 | ≥40 | ≥35 | ≥28 |

| Xmin | 30 | 25 | 20 | |

| 0.2 MPa R.U.L / ℃ | μ0 | ≥ 1 650 | ||

| Density / (g/cm3) | μ0 | ≤2.33 | ≤2.34 | |

| Residual Quartz / % | μ0 | ≤1.5 | ||

| HPLC ( 1450℃×2h ) / % | Xmin ~ Xmax | 0 ~ 0.2 | ||

| CTE / % | μ0 | ≤1.28 | ≤1.30 | |

Specifications of Silica Bricks for Hot Blast Furnace

| Items | Properties | ||

| RG-95 | |||

| Vault, furnace wall bricks | Checkered bricks | ||

| ω(SiO2) / % | μ0 | ≥95 | |

| ω(Al2O3) / % | μ0 | ≤1.0 | |

| ω(Fe2O3) / % | μ0 | ≤1.2 | |

| Open Porosity / % | μ0 | ≤22 | ≤24 |

| Density / (g/cm3) | μ0 | ≤2.33 | ≤2.34 |

| CCS / MPa | μ0 | ≥40 | ≥30 |

| Xmin | 25 | 25 | |

| 0.2 MPa R.U.L / ℃ | μ0 | ≥1650 | |

| Residual Quartz / % | μ0 | ≤1.5 | |

| 0.2 MPa Creep Rate(1550℃) 0h ~ 50h / % | μ0 | ≤0.8 | |

| CTE(1000℃) / % | μ0 | ≤1.26 | |

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

Applications

Silica bricks are acidic refractory materials and play a key role in many high-temperature industrial:

In the metallurgical industry, silica bricks are often used in the carbonization chamber and combustion chamber of the coke oven, as well as the belly of the blast furnace, because of their high temperatures and slag erosion resistance.

In the glass industry, silica bricks are also used in small furnace and the regenerator of the glass melting furnace to ensure the stable operation of glass production.

Silica bricks are also used in ceramic kilns, because of their refractory and heat insulating properties to extend the service life of the equipment and help various industries to produce efficiently.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.