Description

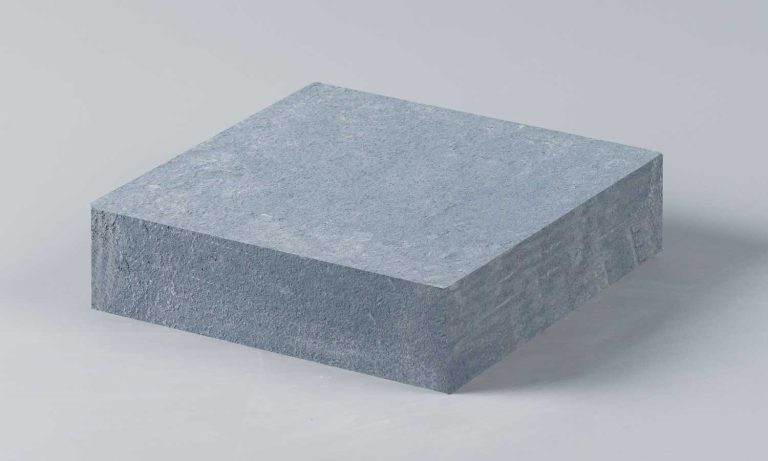

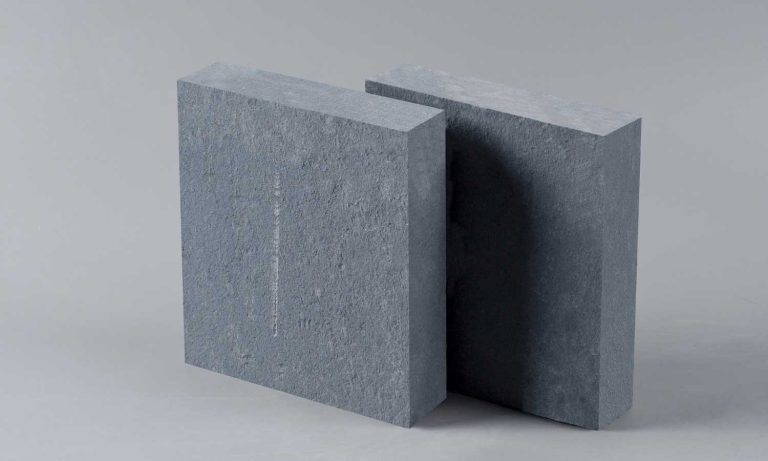

Nano insulation board is a high-performance insulation panel made from nanoporous materials. Using our patented dry forming technology, we blend nano-scale silica materials with specific additives to create an efficient microporous structure. This design achieves thermal conductivity lower than still air and an ultra-thin profile, significantly outperforming traditional materials such as calcium silicate boards and ceramic fiber boards. While delivering superior insulation performance and saving space, it ensures remarkable energy savings in high-temperature environments, making it an ideal choice for industrial furnaces, building insulation, and high-temperature equipment.

Specification

The following table shows the technical specifications of our Nano Insulation Board across different grades , including color, size, thickness, density, coating, working temperature, compressive strength, high-temperature linear shrinkage, and thermal conductivity.

| Items | Grades | ||||

| NIB-400 | NIB-550 | NIB-950 | NIB-1150 | ||

| Color | Off-white | Grey | Off-white | Off-white | |

| Size (mm) | 250*200 / 320*200 | 250*200 / 200*200 | 1000*600, etc. | 600*200, etc. | |

| Thick (mm) | 25~60 | 25~100 | 5~50 | 5~20 | |

| Density (kg/m³) | 400±5% | 550±5% | 280±5% | 320~360 | |

| Coating form | Heat shrink wrap | Heat shrink wrap | Heat shrink wrap Al-foil wrap Fire cloth wrap | Al-foil wrap | |

| Work Temp (℃) | ≤1000 | ≤1100 | ≤1000 | ≤1050 | |

| CCS(MPa) / Press10% | ≥0.5 | ≥0.5 | ≥0.35 | ≥0.5 | |

| HTLSR /% | 800℃×4h | ≤1.5 | ≤1.2 | ≤2.0 | – |

| 1050℃×24h | – | – | – | ≤3.5 | |

| λ / [W/(m▪K)] | 200℃ | – | – | 0.02 | – |

| 400℃ | – | – | 0.023 | – | |

| 600℃ | 0.031 | 0.049 | 0.027 | – | |

| 800℃ | 0.042 | 0.055 | 0.032 | 0.037 | |

| 950℃ | – | – | – | 0.042 | |

| 1000℃ | 0.052 | 0.068 | – | – | |

| 1050℃ | – | – | – | 0.045 | |

Features

- High refractoriness with ultra-low thermal conductivity

- Superior thermal insulation performance and easy installation

- Non-toxic, environmentally friendly, and safe in high-temperature environments

When used as the internal insulation layer of industrial furnaces or high-temperature flue systems, no additional external insulation—such as mineral wool—is required to achieve the desired thermal performance.

Application Advantages

- Ultra-thin insulation layer, enabling compact equipment design

- Low heat storage, reducing heat-up time and improving thermal efficiency

- More uniform temperature distribution, enhancing product consistency and process stability

- Enhanced durability, extending equipment service life while reducing maintenance needs

- Significant energy savings with strong economic benefits

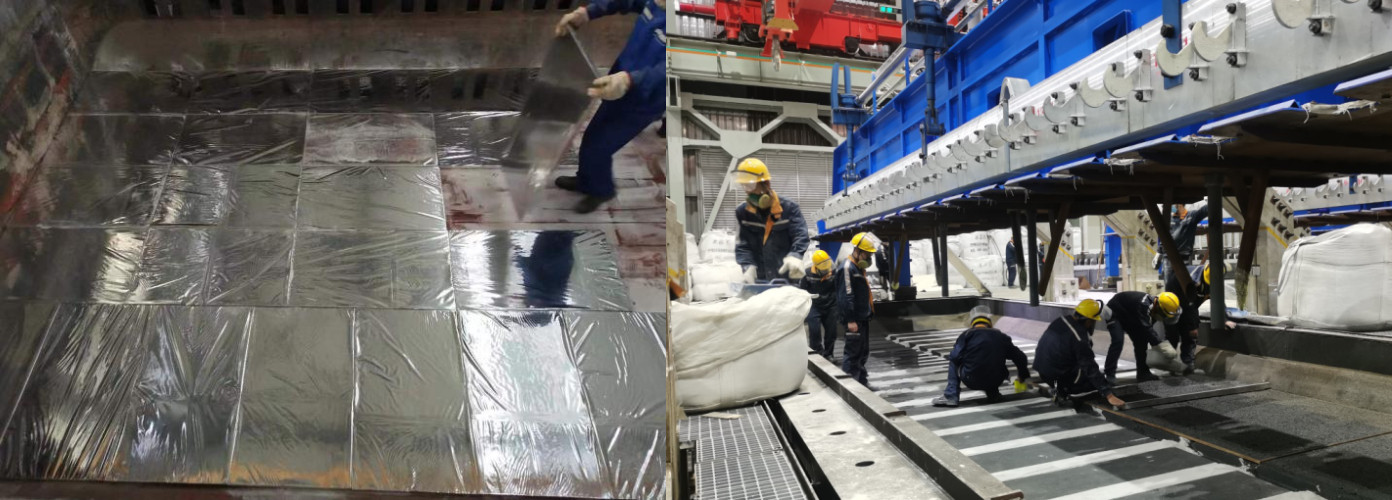

JHYRef Nano Insulation Board Application Cases

Cement Plant Decomposition Kiln Lining Installation Site(JHY400)

Cement Plant Tertiary Air Duct Lining Installation Site(JHY550)

Cement Plant Grate Cooler Lining Installation Site(JHY550)

Aluminum Electrolytic Cell Lining Installation Site(JHY950)

Ladle Lining Installation Site(JHY1150)

Tundish Lining Installation Site(JHY1150)

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

Applications

Nano insulation board, as a thermal insulation material, has wide applications as follows:

- Cement industry: Insulation layer of sintering system, cement mill, fly ash mill.

- Electrolytic aluminum: Bottom, side and top of electrolytic cell.

- Steel industry: Insulation layer of ladle, torpedo tank and refining furnace.

- Power industry: Insulation layer of high-temp flue gas pipeline and high-pressure steam pipeline.

- Petrochemical industry: Insulation layer of cracking furnace and high-temperature steam pipeline.

- Building materials industry: Insulation layer of ceramic kiln, glass kiln, lime kiln and carbon kiln.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.