Description

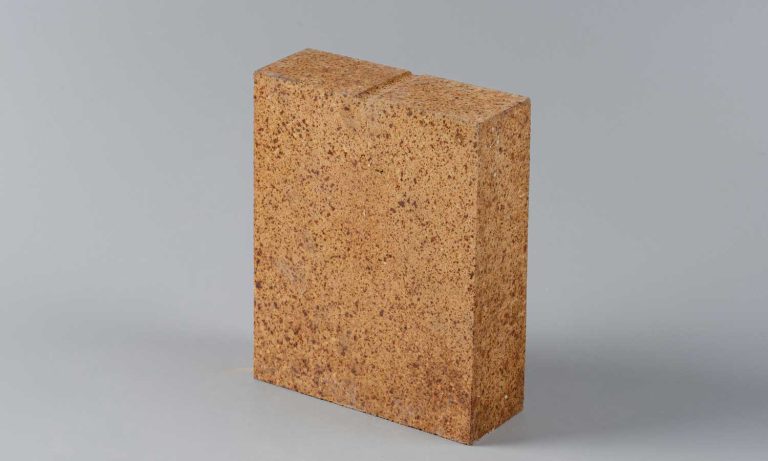

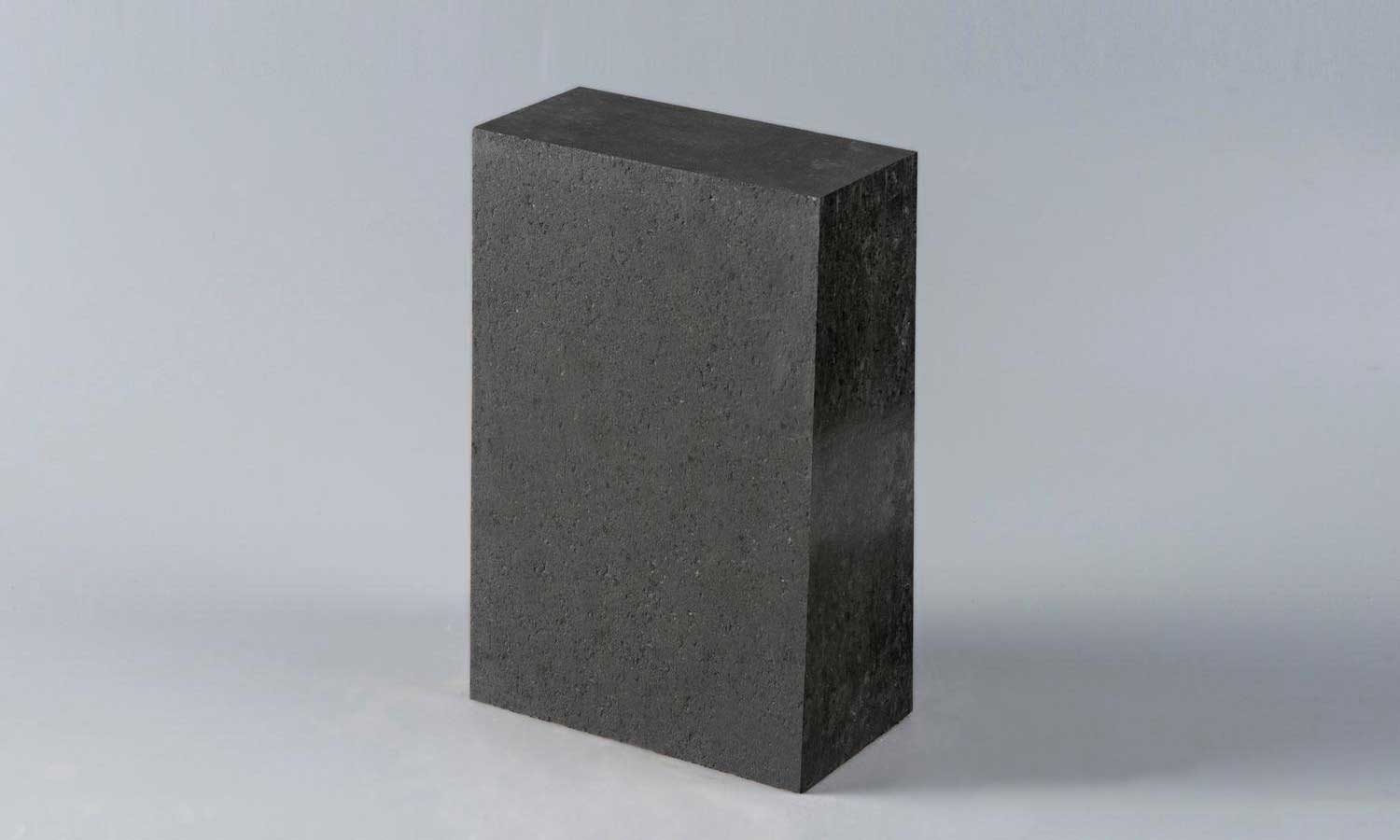

Magnesia Hercynite Brick is a high-performance refractory material mainly composed of pleonaste and high-purity magnesia or fused magnesia, with the addition of additives such as iron powder and alumina micro-powder. It is manufactured through high-pressure forming and high-temperature sintering processes. These bricks feature high compressive and mechanical strength, excellent thermal shock stability, strong corrosion resistance, low thermal conductivity, superior kiln coating adherence, and green environmental protection without pollution.

Specifications

| Item | Grade | |

| MFS-85 | MFS-80 | |

| MgO / % ≥ | 85.0 | 80.0 |

| SiO2 / % ≥ | 1.5 | 2.5 |

| Fe2O3 / % | 5~8 | 5~8 |

| Bulk Density / (g/cm³) ≥ | 3.2 | 3.1 |

| Open Porosity / % ≤ | 15 | 18 |

| CCS / MPa ≥ | 120 | 100 |

| R.U.L (0.2 MPa T0.6) / ℃ ≥ | 1680 | 1650 |

| TSR (1100℃~cold) ≥ | 5 | 5 |

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

Applications

Primarily used in the high-temperature zones of cement rotary kilns. Due to the high temperatures and chemical corrosion that cement rotary kilns endure during production, traditional magnesia-chrome bricks, although performing well, contain Cr2O3(which can form toxic Cr6+compounds), leading to environmental pollution, when combined with the alkali components in the kiln feed. Magnesia Hercynite Bricks completely eliminate the issue of chromium contamination exceeding limits in cement, thus solving the pollution problem.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.