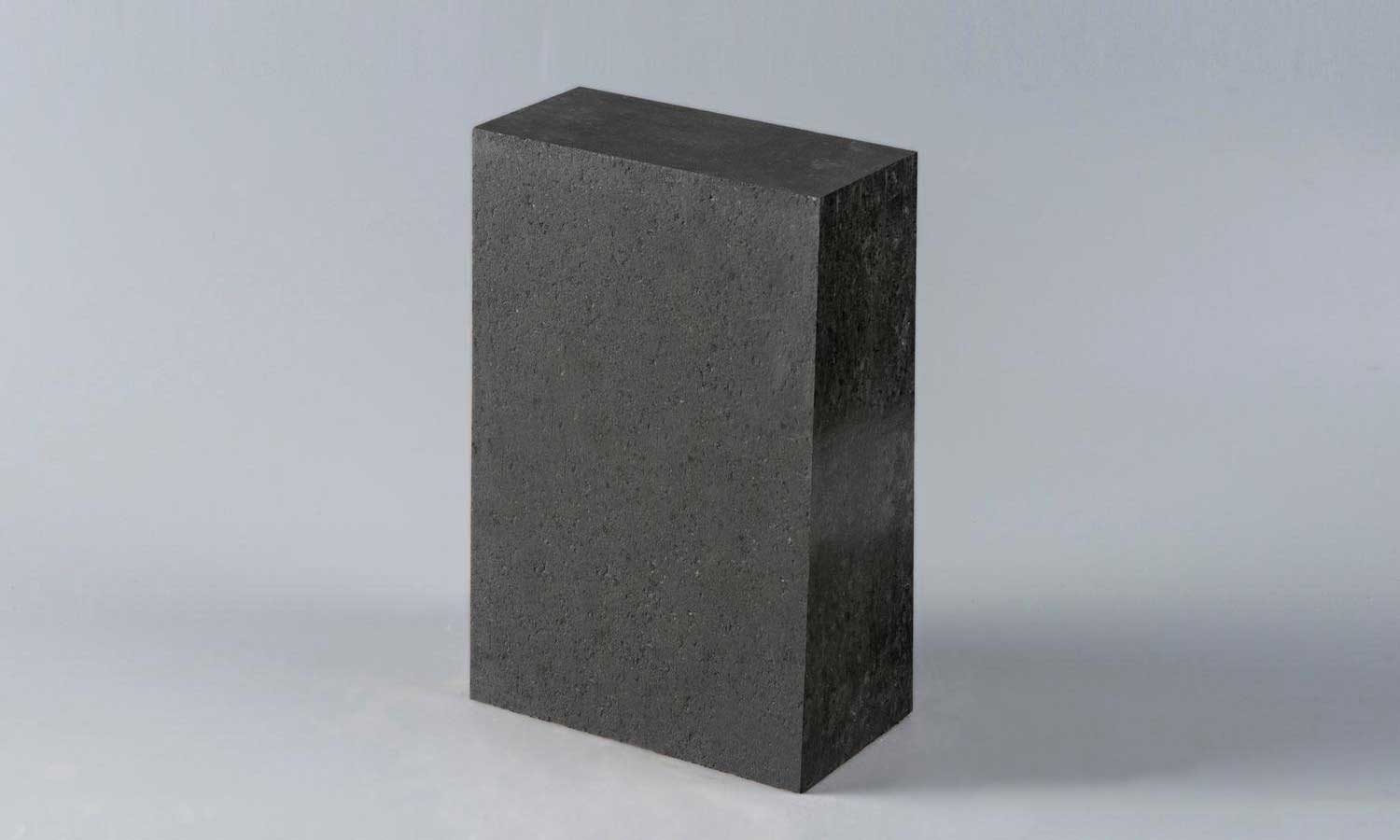

Description

Magnesia-chrome bricks are alkaline refractory products mainly composed of magnesium oxide (MgO) and chromium oxide (Cr2O3), with periclase and spinel as the primary mineral components. These bricks have high refractoriness, high-temperature strength, strong resistance to alkaline slag erosion, excellent thermal stability, and a certain degree of adaptability to acidic slags.

Specification of Magnesia Chrome Brick

| Item | Grade | |||||

| MGe-16A | MGe-16B | MGe-12A | MGe-12B | MGe-8A | MGe-8B | |

| ω(MgO)/%≥ | 50 | 45 | 60 | 55 | 65 | 60 |

| ω(Cr2O3)/%≥ | 16 | 16 | 12 | 12 | 8 | 8 |

| Apparent Porosity/%≤ | 19 | 22 | 19 | 21 | 19 | 21 |

| Cold Crushing Strength /MPa≥ | 35 | 25 | 35 | 30 | 35 | 30 |

| min30 | min20 | min30 | min25 | min30 | min25 | |

| Refractoriness Under Load / 0.2 MPa T0.6/℃ | 1650 | 1550 | 1650 | 1550 | 1650 | 1530 |

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

Applications

Magneisa chrome brick is used for the roof of open-hearth furnaces, the walls and roofs of electric furnaces and the linings of converters and steel ladle working linings, the burning zone of cement rotary kilns, linings of non-ferrous metal smelting furnaces, regenerator of glass kilns, etc.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.