Description

High alumina insulating brick is a kind of heat-insulating refractory product made primarily from bauxite, with an Al2O3 content of no less than 48%. They are mainly produced using bauxite clinker, combined with clay as raw materials, and mixed with binders and sawdust. To enhance the product’s performance, industrial alumina, corundum, sillimanite, kyanite and silica are added in fine powder form to produce products with a bulk density of over 0.4 g/cm³.

Advantages: The characteristics of high alumina insulation bricks include light weight, excellent thermal insulation properties (low thermal conductivity), high refractoriness, excellent thermal stability and mechanical strength.

Related Products

Poly lightweight alumina brick: used for furnaces lining and insulation layers ≤1350℃, more>

Light weight fireclay brick: used as insulating brick, with an alumina content of 30% to 46%, more>

Alumina bubble brick: a type of ultra-high temperature energy-saving thermal insulation brick, more>

Nano insulation board: a micro-porous structure of high-efficiency thermal insulation board, more>

Specification

| Item | Grade | |||||

| LG140-1.2 | LG140-1.0 | LG140-0.8L | LG135-0.7L | LG135-0.6L | LG125-0.5L | |

| ω(Al₂O₃)/%≥ | 48 | |||||

| ω(Fe₂O₃)/%≤ | 2.0 | |||||

| Bulk Density(g/cm³)≤ | 1.2 | 1.0 | 0.8 | 0.7 | 0.6 | 0.5 |

| CCS / MPa ≥ | 4.5 | 3.5 | 2.5 | 2.2 | 1.6 | 1.2 |

| min4.0 | min3.0 | min2.2 | min2.0 | min1.5 | min1.0 | |

| HPLC / % | 1400℃×12 h —2~1.0 | 1350℃×12 h —2~1.0 | 1250℃×12 h —2~1.0 | |||

| λ [W/m·k] (350±25℃) ≤ | 0.55 | 0.50 | 0.35 | 0.30 | 0.25 | 0.20 |

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

Applications

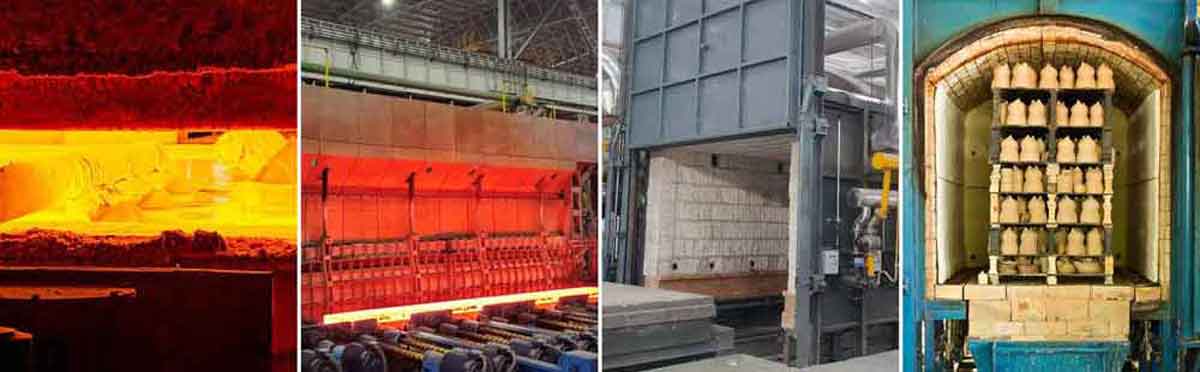

High alumina insulating bricks are Widely used as an insulation layer in reheating furnaces and soaking pits in the steel industry, shuttle kilns and roller kilns in the ceramics industry, and glass melting furnaces in the glass industry. It can also be used as an insulation layer in high-temperature equipment such as cracking furnaces and reforming furnaces in the petrochemical industry.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.