Description

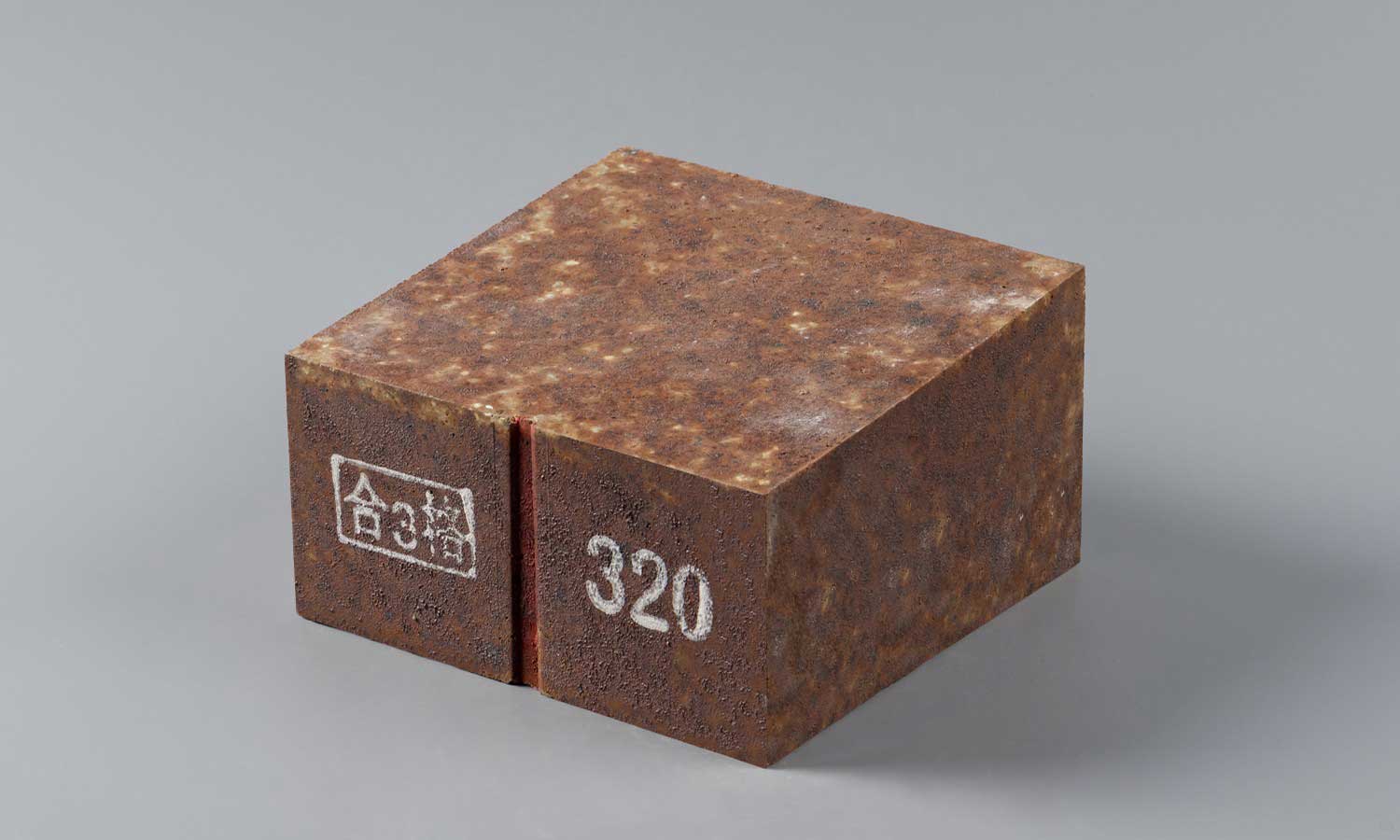

Alumina silicon carbide carbon brick, referred to as ASC bricks, is a new type of refractory bricks with excellent performance, which are made from recycled alumina, silicon carbide, and carbon brick particles through processes such as crushing, screening, blanking, and drying.

The high hardness of alumina and silicon carbide combined with carbon make alumina silicon carbide carbon bricks have high compressive strength and flexural strength, and withstanding mechanical loads and material erosion at high temperatures.

The low expansion coefficient and good thermal conductivity of silicon carbide and carbon, coupled with the mutual cooperation with alumina, make ASC bricks effectively relieve thermal stress, reduce the generation and expansion of cracks when the temperature changes sharply, and have good thermal shock stability.

Raw Materials

| Particle Size / d | Parameter | ||

| 3mm <d≤5mm | ω(Al2O3)≥60% | ω(SiC)≥2% | ω(C)≥6% |

| 1mm <d≤3mm | ω(Al2O3)≥52% | ω(SiC)≥3% | ω(C)≥6% |

| 0mm <d≤1mm | ω(Al2O3)≥48% | ω(SiC)≥3% | ω(C)≥6% |

Specifications

| Items | Parameter | |

| ω(Al2O3) / % | μ0 | ≥60 |

| ω(SiC + F.C) / % | μ0 | ≥15 |

| ω(F.C) / % | μ0 | ≥8 |

| Open Porosity / % | μ0 | ≤8 |

| CCS/ MPa | μ0 | ≥45 |

| Bulk Density/(g/cm3) | μ0 | ≥2.8 |

| Note: F.C represents the free carbon in SiC. μ0 represents the approved value of qualified quality. | ||

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

Applications

Alumina silicon carbide carbon bricks are mainly used as linings in ladles in the steel industry, and can also be used in the walls and bottoms of blast furnaces, converters, and electric furnaces. In addition, they are also widely used in non-ferrous metal industries, glass kilns, and waste incinerators.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.