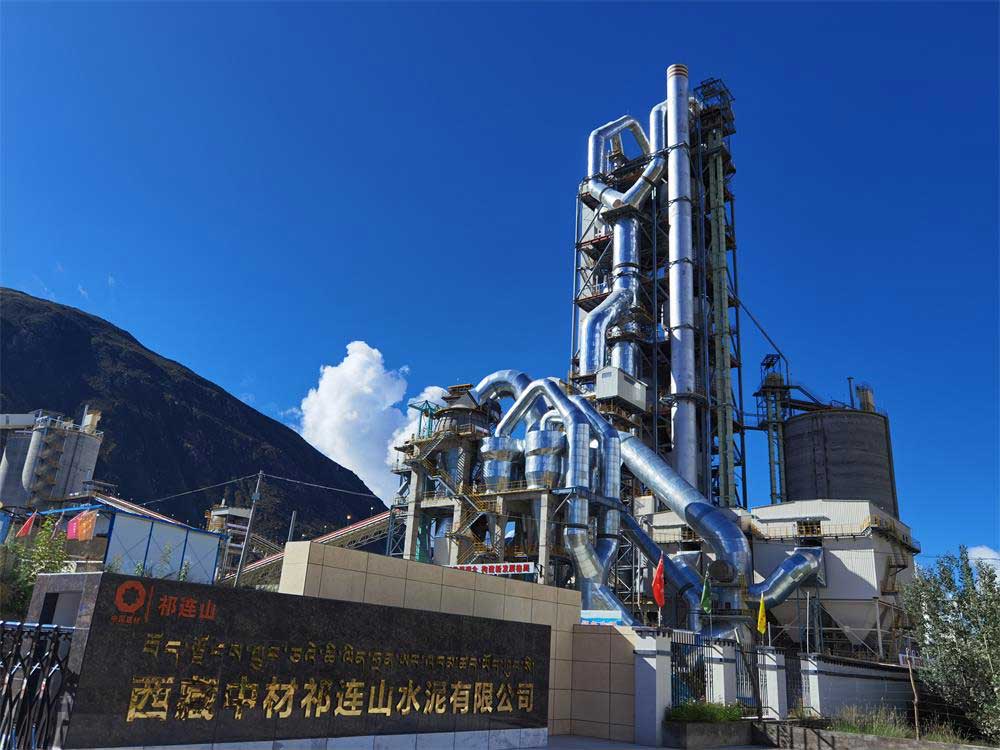

Client: Qilianshan, Leading Cement Producer in Gansu Province China

Challenge:

The client faced recurring operational issues with the rotary kiln, preheater, and cooler zones in their cement production line. Frequent maintenance and heat loss led to high costs and operational inefficiencies.

Solution:

JHY Ref provided a full range of tailored refractory materials and technical support for the plant’s key zones:

- Rotary Kiln: High alumina bricks for sintering zone

- Cooler: Silicon carbide bricks and castables for better heat resistance

- Preheater: Alkali-resistant bricks to handle harsh conditions

- Customization: Specialized refractory castables for critical areas

We also offered on-site installation guidance to ensure optimal performance.

Results:

- Extended service life: Reduced maintenance intervals by 50%

- Enhanced performance: Increased energy efficiency, resulting in a 15% reduction in fuel costs

- Reliable operation: Improved heat retention and minimized downtime

Key Benefits:

- On-time delivery of 1200 tons of refractory materials

- Cost-effective solutions that met the plant’s long-term need

- Full technical support and training for seamless integration