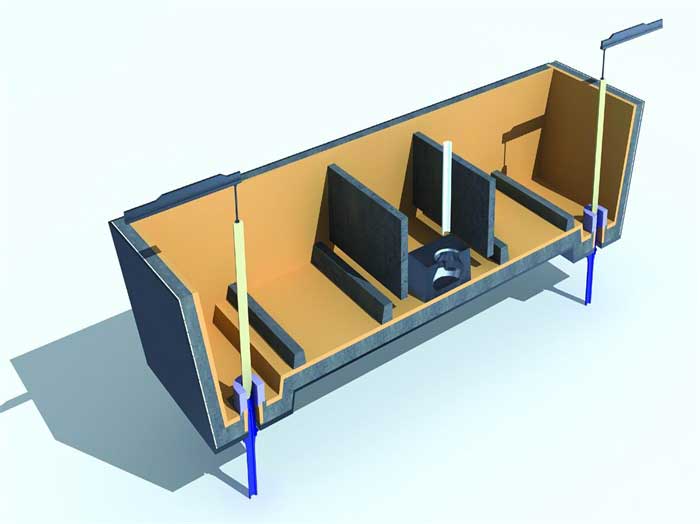

The tundish is a key piece of equipment in the continuous casting process, located between the steel ladle and the mold. It is primarily used to receive molten steel from the steel ladle and distribute it evenly to each mold. Additionally, the tundish helps maintain the stability of the steel temperature, purify the molten steel, and regulate the flow of steel.

The refractory materials used in tundishes need to possess high-temperature stability, erosion resistance, thermal shock resistance, and good insulating properties to meet the complex conditions of high temperatures, erosion, and scouring during the continuous casting process. Typically, the working layer uses magnesia-based dry vibratable materials, while the permanent layer employs castables. There are also refractory materials for key components, such as slag dams and flow regulators.

Our Services:

- Overall design of kiln and furnace

- Optimization of partial design of kiln and furnace

- Refractory configuration for different parts of kiln and furnace

- Comprehensive construction of refractory materials

- Monitoring of refractory materials’ service life

- Analysis of issues in refractory usage

- Full-process technical tracking and service