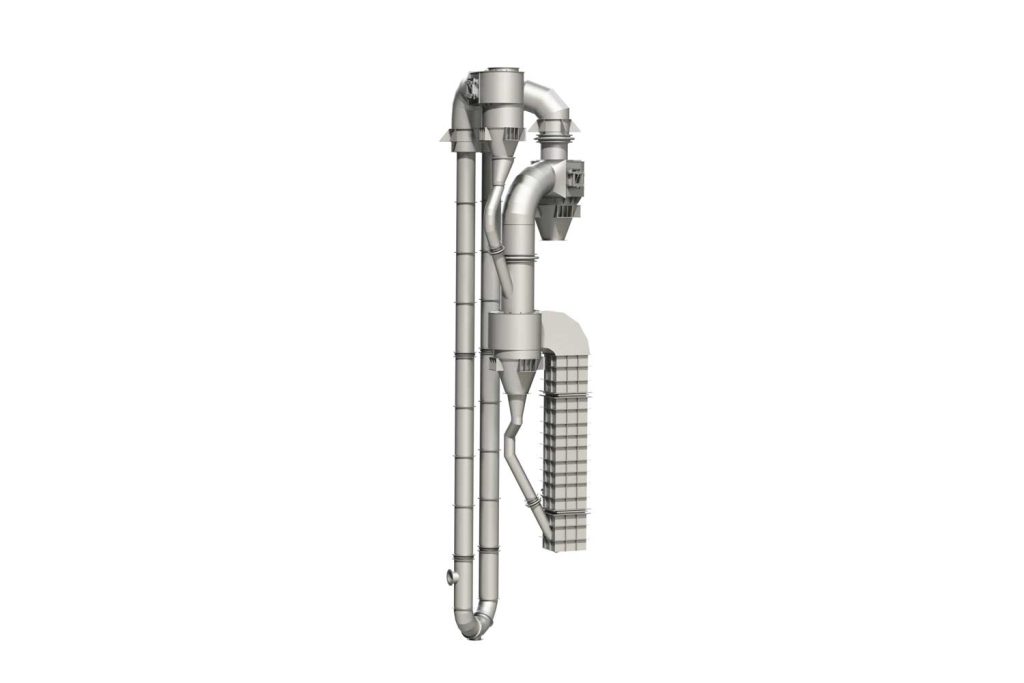

The preheater is an essential piece of equipment in modern cement production. It heats the raw meal by exchanging heat with high-temperature gas streams (such as exhaust gas from the kiln tail), raising its temperature from ambient to around 300°C to 800°C. When the preheated raw meal enters the rotary kiln, it can complete the calcination process more quickly, reducing fuel consumption and improving energy efficiency.

This area is mainly subjected to cyclic erosion by chlorine and alkali, as well as the scouring action of materials. Therefore, these equipment components generally use Alumina-containing refractory bricks and castable . In addition, to save energy, calcium silicate boards or nano-insulation boards are also laid.

Our Services:

- Preheater Design

- Preheater Condition Analysis

- Refractory Configuration

- Integrated Refractory Material Construction

- Refractory Material Service Life Testing

- Analysis of Refractory Material Usage Issues

- Full-Process Technical Follow-up Services

Related products: