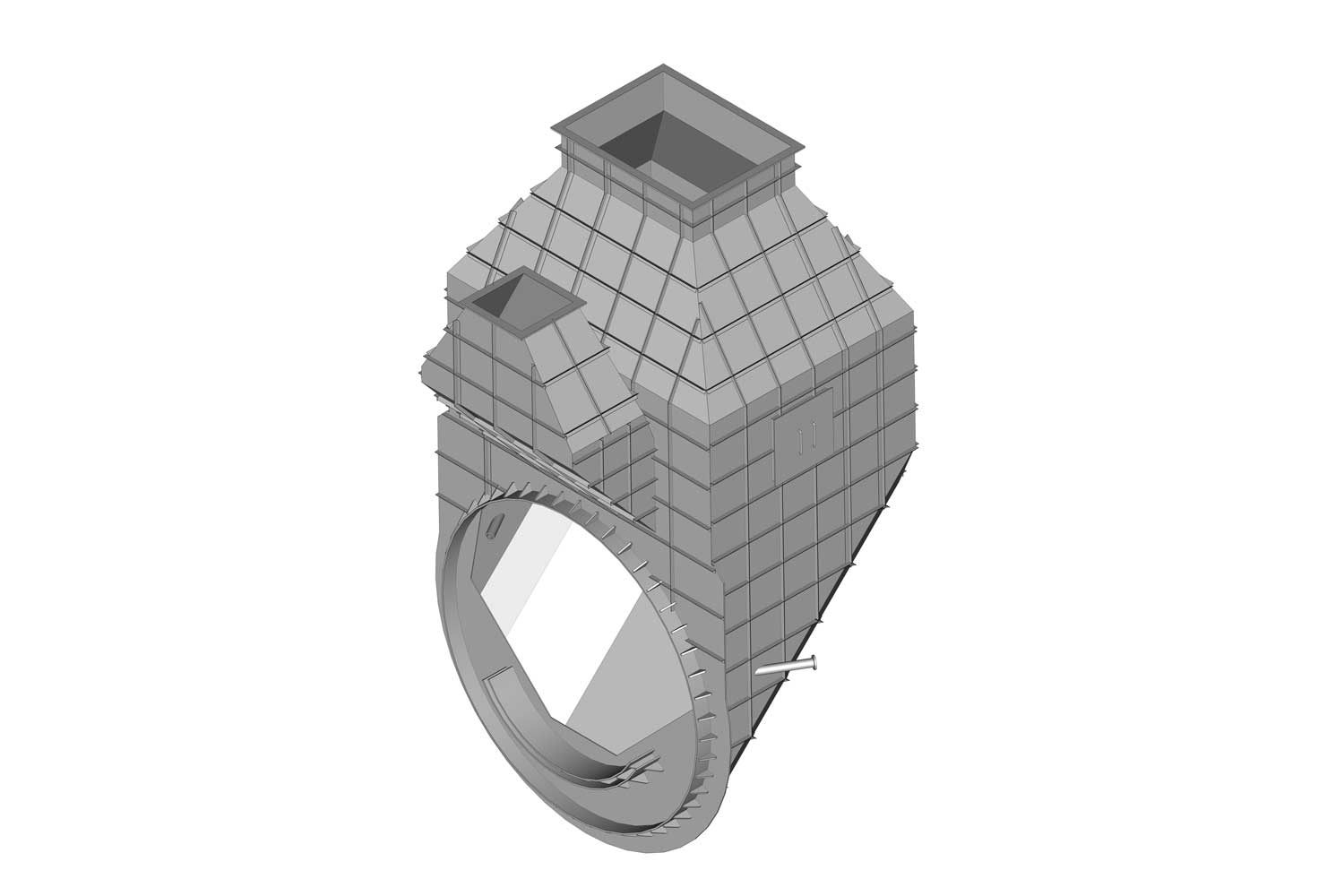

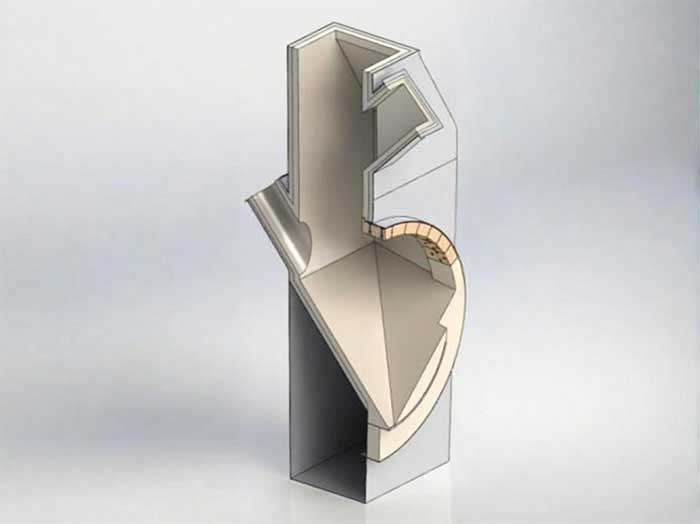

The material, after passing through the decomposition furnace, enters the rotary kiln via the kiln tail chamber for further calcination. The kiln tail chamber directs the high-temperature exhaust gas generated in the rotary kiln to the decomposition furnace or preheater to preheat the raw meal. A well-designed kiln tail chamber can reduce the secondary dust entrainment of the raw meal when entering the rotary kiln, preventing the material from being lifted by the gas flow, thereby reducing the system’s resistance and heat consumption.

The working conditions of the Kiln inlet chambers are quite complex. It typically requires refractory that can withstand high temperatures, resist erosion, wear-resistant and capable of resisting scaling. Refractory containing silicon carbide can achieve good results in this regard.

Our Services

- Kiln inlet chambers Design

- Refractory Configuration

- Integrated Refractory Material Construction

- Refractory Material Service Life Testing

- Analysis of Refractory Material Usage Issues

- Full-Process Technical Follow-up Services

Related products