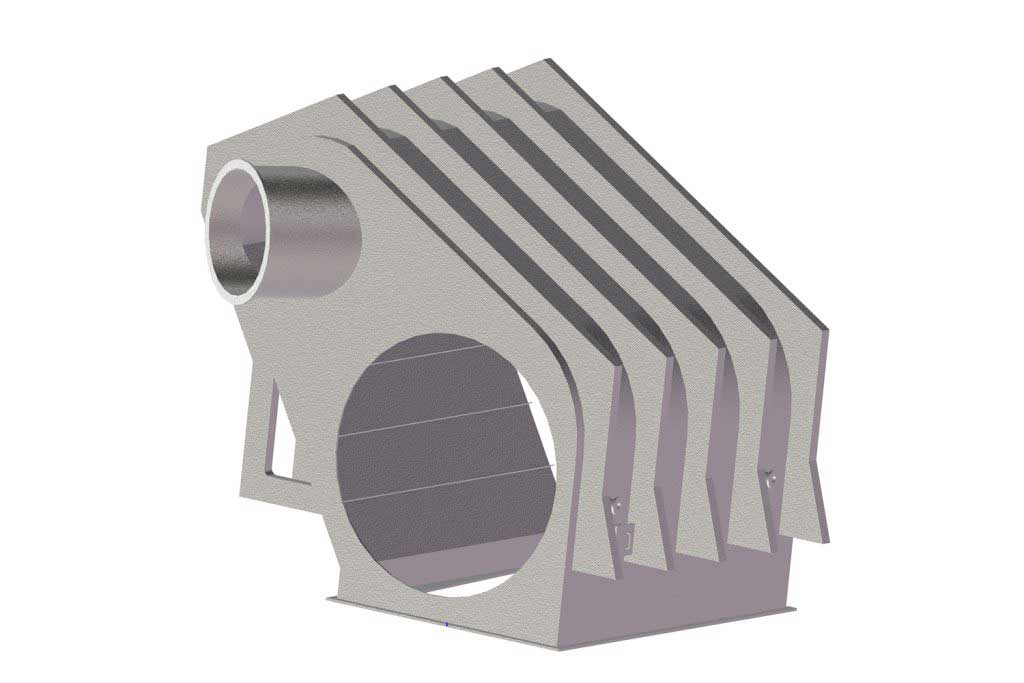

The kiln hood is the passage through which clinker is discharged from the rotary kiln. The clinker enters the grate cooler through this part, while the hot gas is directed into the decomposition furnace via the tertiary air duct.The refractory in this area are capable of withstanding high temperatures, the erosion of flue gases, and temperature fluctuations.

The refractory for the kiln hoods need to have high-temperature stability, wear resistance, erosion resistance, and good thermal shock resistance. High-alumina refractory and prefabricated hanging bricks can be used. During the construction of castables, it is essential to reserve exhaust holes to prevent spalling or bursting of the castables during the baking process due to rapid temperature increase.

Our Services

- Cement Rotary Kiln Design

- Refractory Material Configuration for Different Zones

- Integrated Refractory Material Construction

- Analysis of Refractory Material Usage Issues

- Full-Process Technical Follow-up Services

Related products