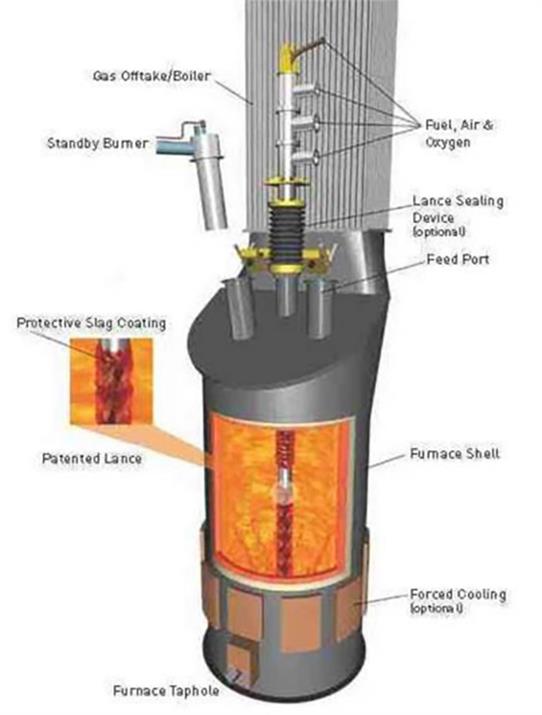

The Isasmelt furnace (ISA furnace) is an efficient submerged, top-blown, oxygen-enriched bath smelting method. The core technology involves using a specially designed lance to forcefully inject oxygen-enriched air into the molten bath, creating intense agitation within the bath. This agitation accelerates the rate of chemical reactions and fully utilizes the heat released from the oxidation of sulfur and iron in the concentrate for smelting. During the smelting process, newly fed materials are instantly surrounded by the high-temperature molten bath and undergo up-and-down and side-to-side tumbling with the forced flow of the molten material.

In the copper smelting Isasmelt furnace (ISA furnace), the refractory materials are subjected to high temperatures, strong chemical erosion, and intense scouring by molten materials and gases. This is particularly the case in high-temperature areas and the most severely eroded parts, such as the furnace walls and bottom, where magnesia-chrome bricks are used.

Our Services:

- Overall design of kiln and furnace

- Optimization of partial design of kiln and furnace

- Refractory configuration for different parts of kiln and furnace

- Comprehensive construction of refractory materials

- Monitoring of refractory materials’ service life

- Analysis of issues in refractory usage

- Full-process technical tracking and service