The primary function of the grate cooler is to rapidly cool the high-temperature clinker (usually at temperatures between 1000°C and 1300°C) discharged from the rotary kiln down to a lower temperature (generally below 200°C). Rapid cooling helps prevent the clinker from undergoing excessive sintering or melting at high temperatures, thereby ensuring the quality and strength of the clinker.

The refractory materials for coolers need to meet multiple requirements, including high-temperature resistance, wear resistance, erosion resistance, and thermal shock stability. Different types of refractory materials are used depending on the specific location. For example, castables containing silicon carbide and steel fibers can be used, and in some areas, pre-bricks are also applicable.

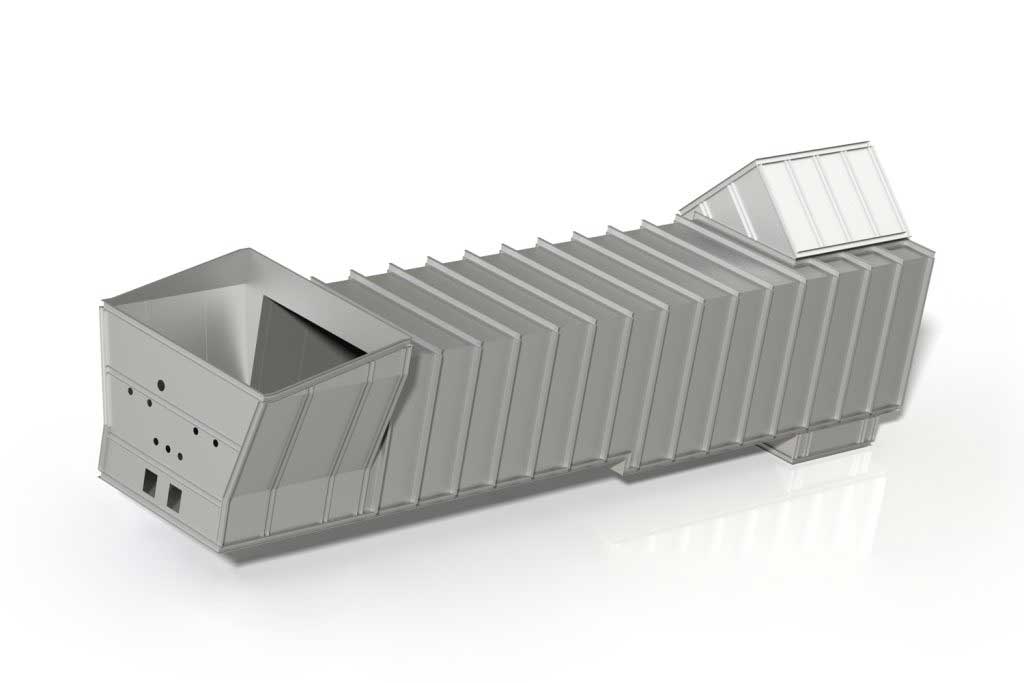

Related products