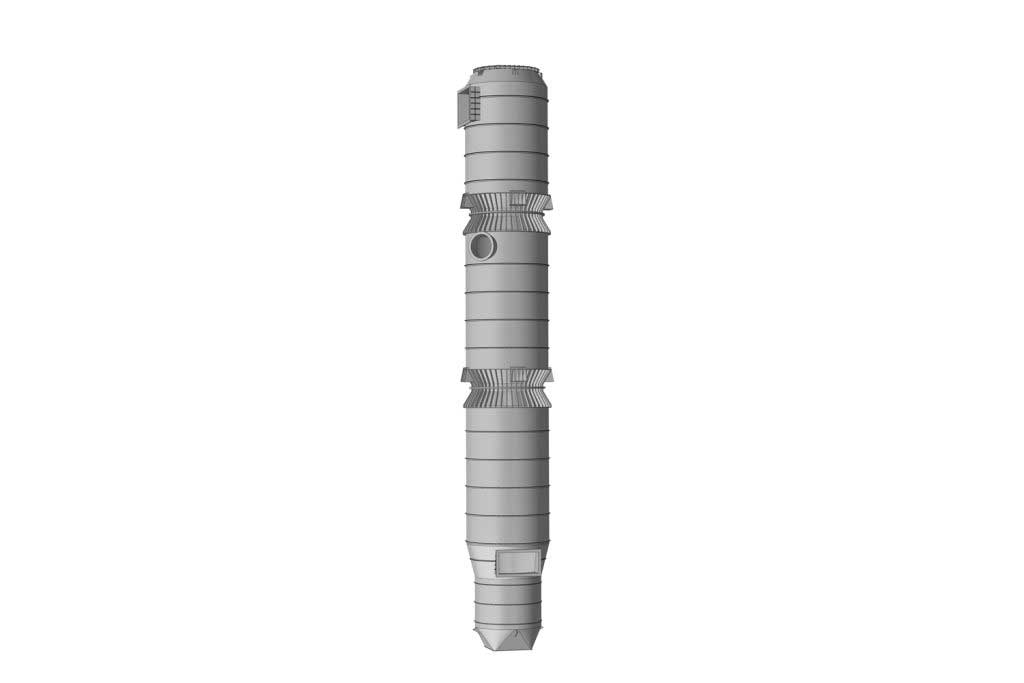

The cement decomposition furnace significantly enhances the efficiency, quality, and environmental performance of cement production through multiple functions, including the decomposition of calcium carbonate in raw meal, improvement of thermal efficiency, optimization of the calcination process, reduction of kiln scaling and blockages, and mitigation of environmental pollution. The application of the decomposition furnace is a crucial technological support for the modern cement industry to achieve high efficiency, energy saving, and sustainable development.

The temperature of the calciners is higher than that of the preheater. In this part, silicon carbide can be added to the refractory to enhance their wear resistance, with alumina-containing refractory being the primary choice.

The temperature inside the rotary kiln is very high, reaching up to 1450°C, especially in the Clinkering zone. This requires refractory materials that can withstand high temperatures, resist erosion, wear-resistant. Magnesia-chrome bricks were previously used in this area, but now magnesia-spinel bricks are commonly employed.

Our Services

- calciners Design

- calciners Condition Analysis

- Refractory Configuration

- Integrated Refractory Material Construction

- Refractory Material Service Life Testing

- Analysis of Refractory Material Usage Issues

- Full-Process Technical Follow-up Services

Related products