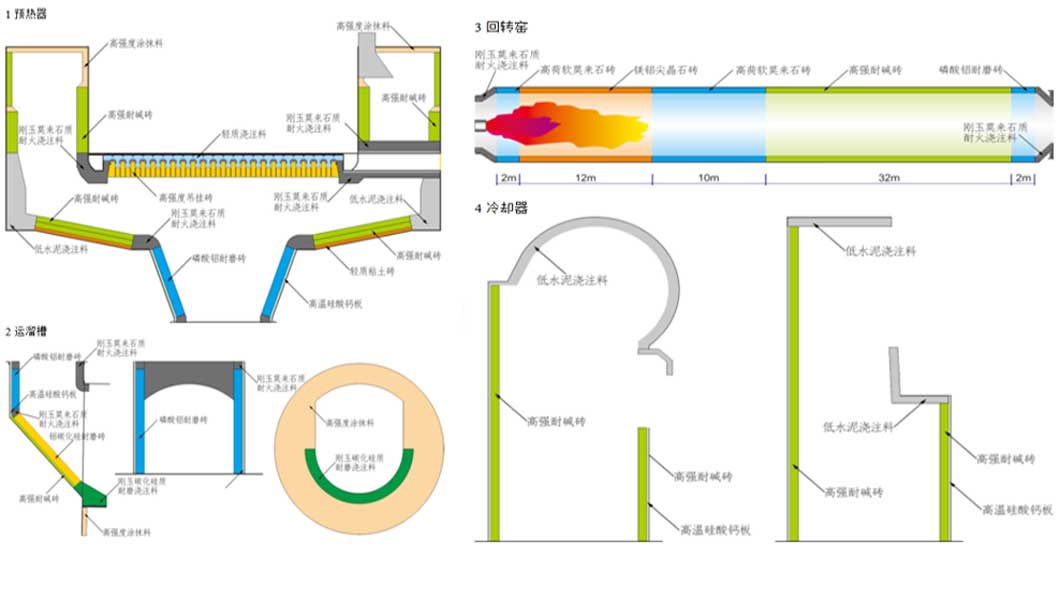

1. Customized Refractory Material Solutions

Tailored refractory materials and application solutions designed to meet clients’ unique process flows and operating conditions, ensuring exceptional performance. Each solution is meticulously engineered to deliver maximum durability, energy efficiency, and operational reliability.

Clients are supported from the following dimensions:

- Significantly extended service life and reduced maintenance downtime.

- Precise material selection based on specific process requirements.

- Dedicated formula development for specialized application scenarios.

2. Technical Support and Professional Consultation

As a trusted partner, we provide comprehensive technical support spanning material selection, installation guidance, and post-installation performance optimization. Through in-depth analysis of client needs, we empower informed decision-making and efficiently resolve on-site technical challenges.

Our support encompasses:

- Performance failure diagnostics and system improvement planning

- Application scenario analysis and performance optimization recommendations

- On-site technical guidance and real-time problem-solving

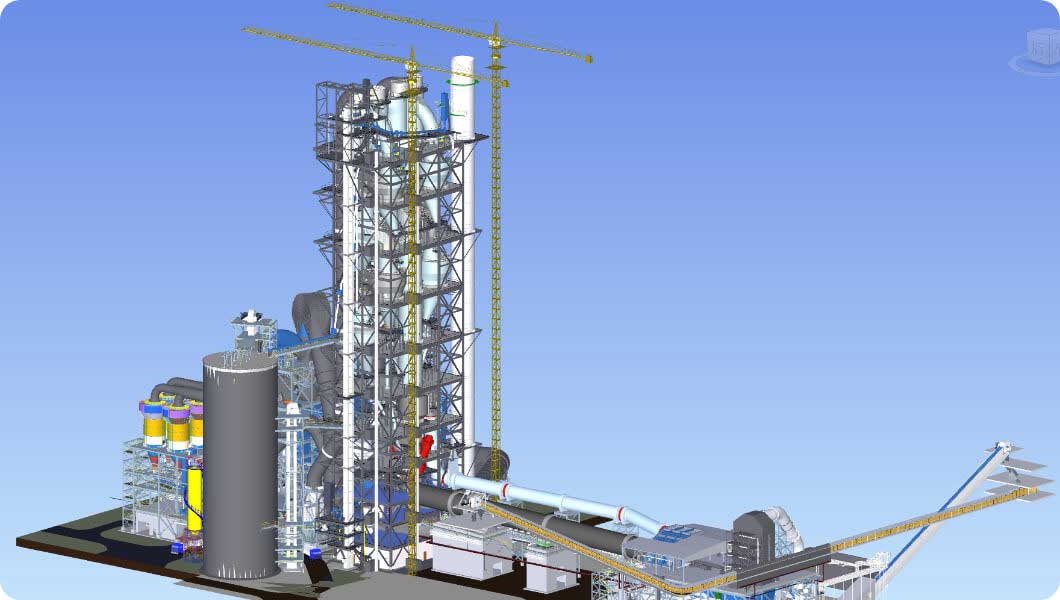

3. Engineering Design and Installation Services

From conceptual design to final commissioning, we deliver turnkey refractory engineering solutions encompassing lining design, structural calculations, installation support, and full-process supervision services, ensuring optimal performance and safety of high-temperature equipment.

Competitive services include:

- On-site supervision and project management support ensuring implementation quality

- CAD-based precise refractory lining design

- Detailed customized installation guidelines with best practice sharing

4. Product Innovation and Sustainability Support

We specialize in developing advanced, sustainable refractory solutions that empower clients to reduce emissions, enhance energy efficiency, and achieve ESG goals. Through continuous technological innovation, we deliver superior, cleaner, and more efficient materials, driving the industry toward low-carbon environmental stewardship.

Key Sustainability Initiatives:

- R&D-driven efficiency upgrades and cost optimization

- Development of Low-carbon recyclable refractory products