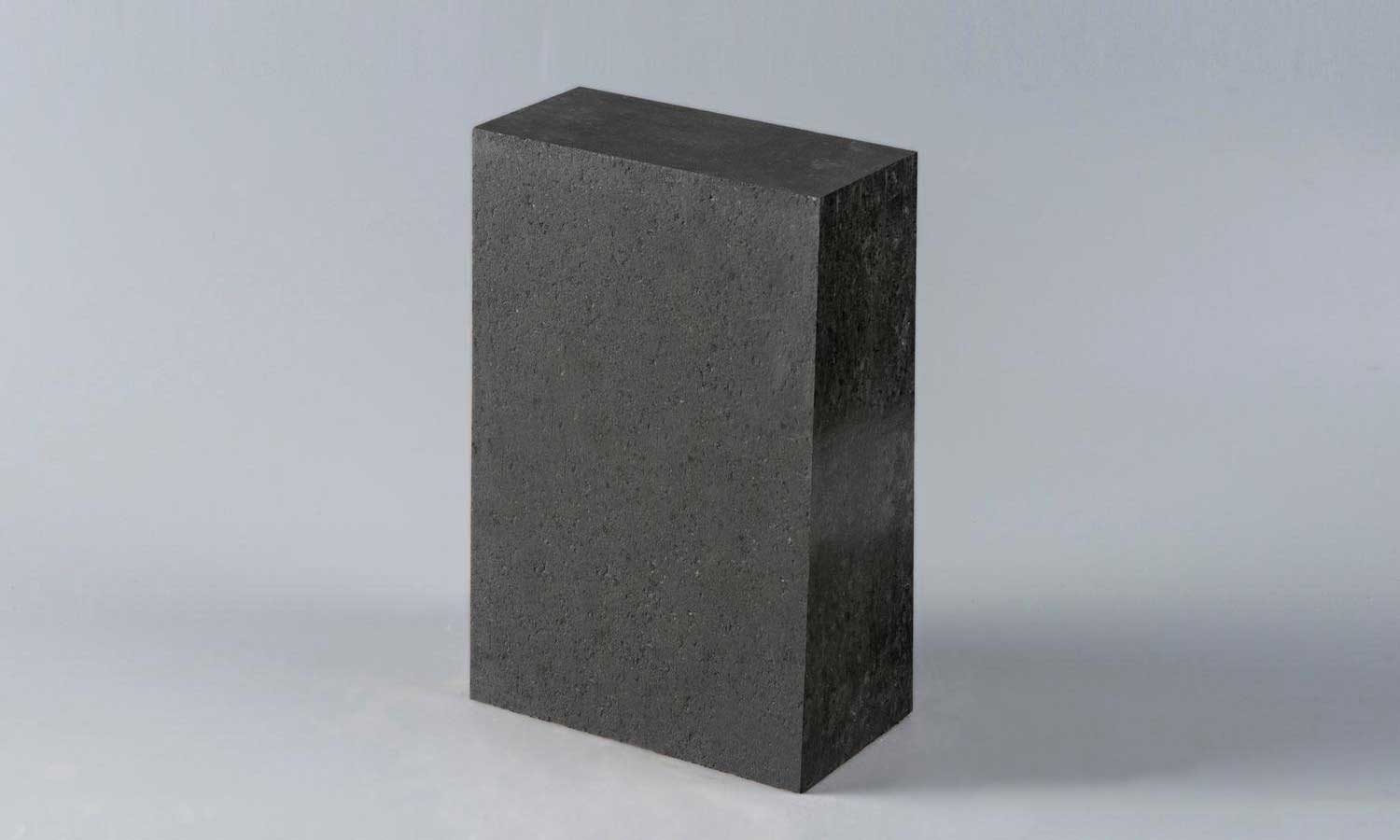

Description

Magnesia-alumina spinel bricks are refractory materials primarily composed of magnesite (MgO) and bauxite (Al2O3), which form the spinel phase (MgAl2O4)through sintering. Spinel is a mineral with a high melting point, excellent thermal stability, and corrosion resistance. The adding of spinel enhances the overall performance of the bricks, especially high-temperature resistance, corrosion resistance and thermal shock resistance.

Specifications of Magnesia Alumina Spinel Brick

| Item | Grade | |||

| MA—90 | MA—85 | MA—80 | MA—75 | |

| ω(MgO)/%≥ | 90 | 85 | 80 | 75 |

| ω(Al₂O₃)/% | 3~8 | 5~12 | 8~17 | 8~12 |

| Apparent Porosity/%≤ | 17 | 17 | 16 | 19 |

| Bulk density/(g/cm³)≥ | 2.90 | 2.95 | 2.95 | 2.85 |

| Cold Crushing Strength/MPa≥ | 45 | 45 | 55 | 40 |

| 40 | 40 | 50 | 35 | |

| Refractoriness Under Load / 0.2 MPa T0.6/℃≥ | 1700 | 1700 | 1700 | 1650 |

| Thermal Shock Resistance(1100℃~cold)≥ | 3 | 8 | 12 | 8 |

Standard Brick Sizes

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

VDZ Standard

| VDZ Standard | ||||||

| Brick Type | Size | Diameter | volume | |||

| a | b | h | l | D1) | ||

| mm | mm | mm | mm | mm | dm3 | |

| B322 | 76.5 | 66.5 | 220 | 198 | 3366 | 3.11 |

| B422 | 75.0 | 68.0 | 220 | 198 | 4714 | 3.11 |

| B622 | 74.0 | 69.0 | 220 | 198 | 6512 | 3.11 |

ISO Standard

| ISO Standard | ||||||

| Brick Type | Size | Diameter | volume | |||

| a | b | h | l | D1) | ||

| mm | mm | mm | mm | mm | dm3 | |

| 320 | 103.0 | 89.0 | 200 | 198 | 3000 | 3.8 |

| 420 | 103.0 | 92.5 | 200 | 198 | 4000 | 3.87 |

| 620 | 103.0 | 96.2 | 200 | 198 | 6176 | 3.94 |

| 322 | 103.0 | 88.0 | 220 | 198 | 3080 | 4.16 |

| 422 | 103.0 | 91.5 | 220 | 198 | 4017 | 4.24 |

| 622 | 103.0 | 95.5 | 220 | 198 | 6160 | 4.32 |

| 425 | 103.0 | 90.0 | 250 | 198 | 4038 | 4.78 |

| 625 | 103.0 | 94.5 | 250 | 198 | 6176 | 4.89 |

| 825 | 103.0 | 96.5 | 250 | 198 | 8077 | 4.94 |

Advantages of Magnesia Alumina Spinel Brick

Magnesia alumina spinel bricks feature low apparent porosity, high CCS, high modulus of rupture at high temperature, corrosion resistance, erosion resistance, good thermal shock stability. Magnesia alumina spinel brick is an ideal substitute for magnesia chrome bricks, an environmentally friendly product that eliminates Cr6+ pollution.

Applications

Magnesia-alumina spinel bricks serve as an ideal substitute for magnesia chrome bricks due to their superior eco-friendliness. Magnesia-alumina spinel bricks are widely used for the linings and upper cones of steel-making converters, electric furnaces, and refining furnaces. They are also applied in non-ferrous smelting furnaces (copper, nickel, lead, and zinc), as well as in cement rotary, lime, and ceramic kilns.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.