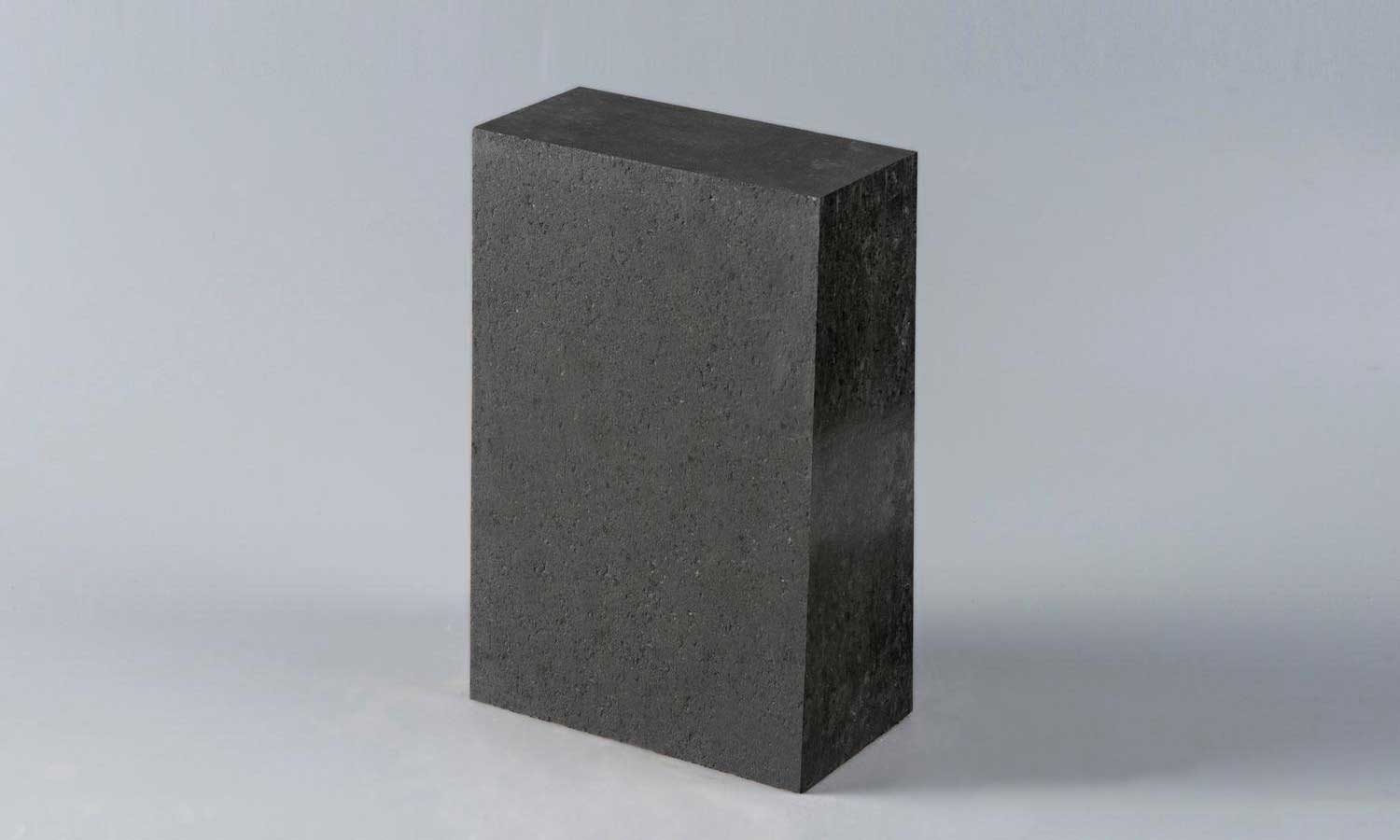

Description

Magnesia-alumina-chrome composite spinel bricks are made from magnesia, synthetic spinel and a small amount of ferrochrome ore as the main raw materials, formed under high pressure and fired at medium to high temperatures. It is an upgraded product of pure magnesia bricks and magnesia-alumina bricks. Compared to the same base magnesia-alumina bricks, it shows significant improvements in performance, including higher load softening temperature and better thermal shock resistance. These bricks are primarily used in high-temperature industrial kilns, especially at the kiln roof, areas exposed to intense thermal shock and regions subjected to prolonged high-temperature load.

Specification

| Item | Grade | |

| MAC—80 | MAC—85 | |

| ω(MgO)/%≥ | 80 | 85 |

| ω(Al₂O₃)/% | 6~10 | 5~8 |

| ω(Cr₂O₃)/% | 4~6 | 3~5 |

| Apparent Porosity/%≤ | 17 | 17 |

| Bulk Density/(g/cm³)≥ | 3.0 | 2.95 |

| Cold Crushing Strength/MPa≥ | 45 | 45 |

| Refractoriness Under Load / 0.2 MPa T0.6/℃≥ | 1700 | 1700 |

| Thermal Shock Resistance(1000℃~Cold)≥ | 5 | 8 |

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

ISO – CE – SGS Certifications & Patents for Refractory Bricks and Castables

Applications

The roof and lining of high-temperature furnaces in the steel industry, volatile kilns of Zinc and the roof of non-ferrous metal smelting furnaces, regenerator of glass kilns.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.