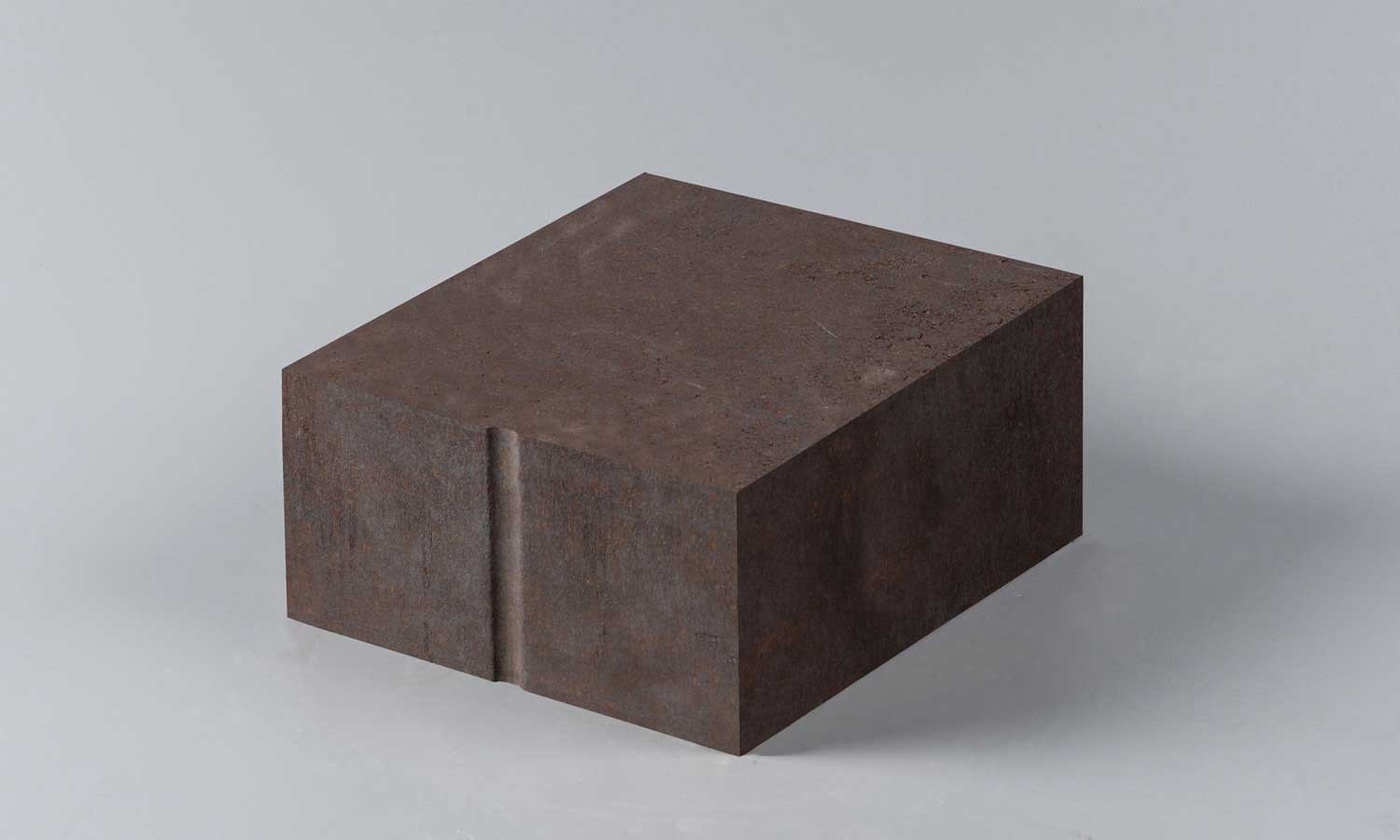

Description

High chrome bricks refer to refractory bricks with a chromium oxide content of not less than 75% and a total content of chromium oxide, alumina and zirconium oxide of not less than 98%.

They are mainly made of industrial chromium oxide and industrial alumina as the main raw materials, sometimes with a small amount of zirconium oxide added, through a high-temperature sintering process.

High chrome bricks have the advantages of high refractoriness, good thermal shock resistance, good slag erosion resistance, strong oxidation resistance, excellent mechanical properties, and good thermal and electrical conductivity.

Specifications

| Items | Grade | |||

| GGZ-75 | GGZ-85 | GGZ-90 | GGZ-95 | |

| ω(Cr2O3)/% | ≥75 | ≥85 | ≥90 | ≥95 |

| ω(Cr2O3+Al2O3+ZrO2)/% | ≥98 | ≥98 | ≥98 | ≥98 |

| ω(SiO2)/% | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 |

| ω(Fe2O3)/% | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 |

| ω(K2O+Na2O)/% | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 |

| Open Porosity /% | ≤18 | ≤18 | ≤16 | ≤16 |

| Density/(g/cm3) | ≥3.90 | ≥4.20 | ≥4.22 | ≥4.25 |

| CCS/ MPa | ≥120 | ≥120 | ≥120 | ≥120 |

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

Applications

1. High chrome bricks are commonly used as lining materials for steelmaking converters and electric furnace walls.

2. High chrome bricks are used as lining materials in synthetic ammonia converters and gasifiers in fertilizer production, as well as cracking furnaces and reforming furnaces in petrochemicals.

3. Used as lining materials for coal gasifiers in the chemical industry.

4. Used as refractory materials for kiln walls, kiln roofs and other parts in ceramic kilns.

5. High chrome bricks can also be used for the lining of waste incinerators to resist high temperature and corrosive gas erosion.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.