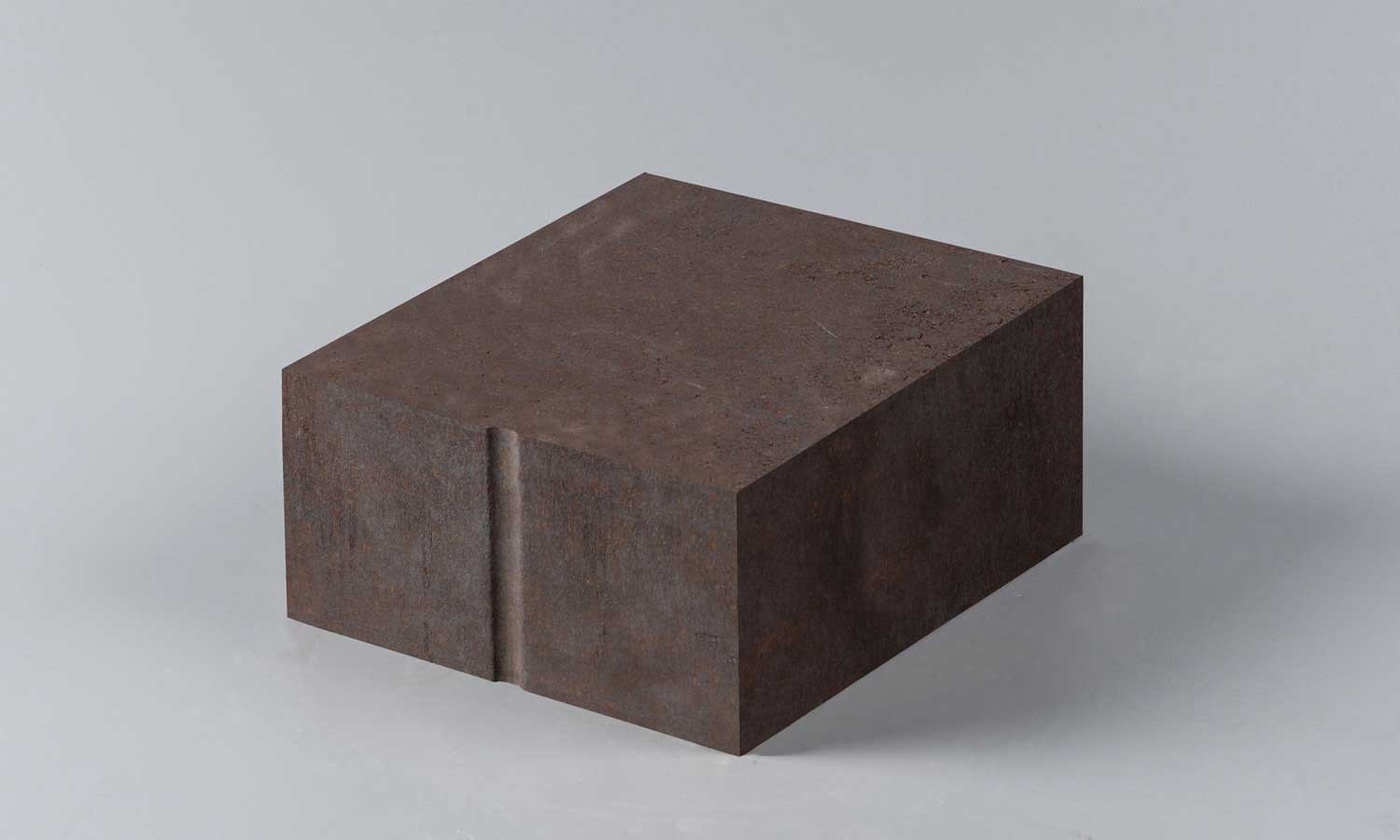

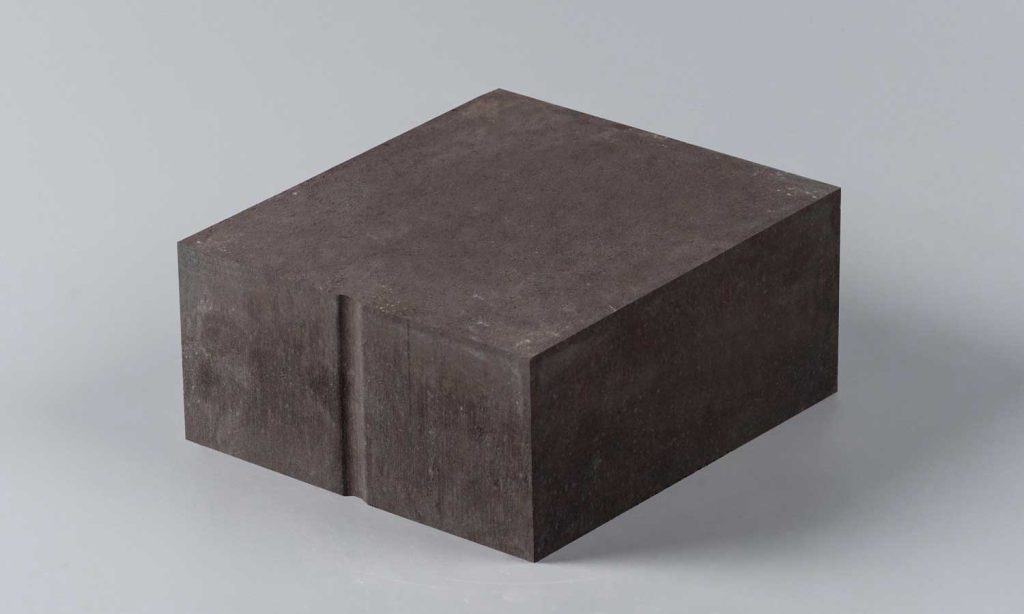

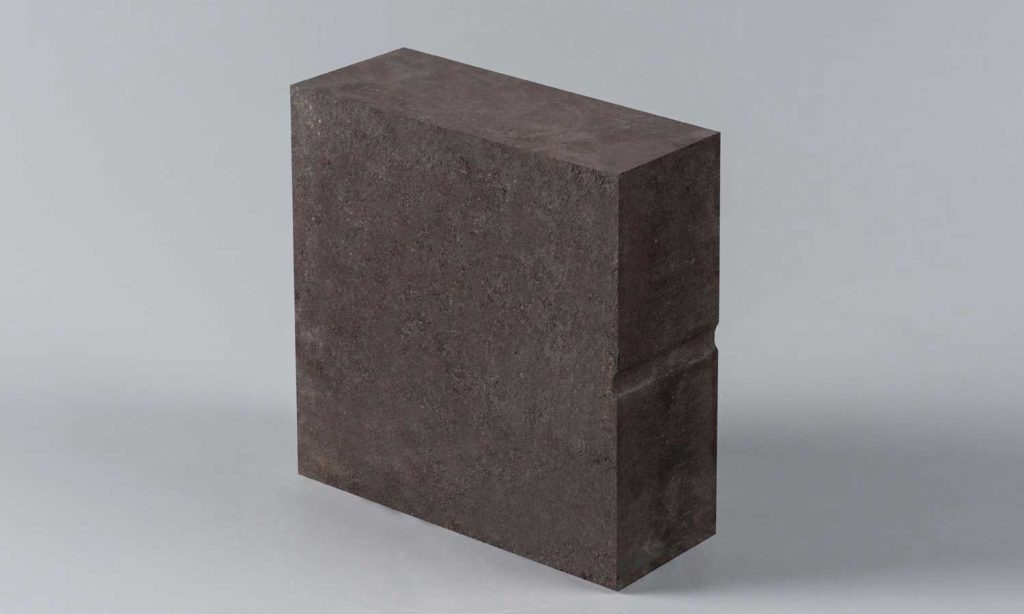

Description

Fused rebonded magnesia-chrome brick is generally made by first melting lightly burned magnesia and chromite in an electric arc furnace to produce fused magnesia-chrome sand. Then this sand is crushed, ground, proportioned, shaped and sintered to manufacture the final product. These bricks have a high degree of direct bonding, low impurity content, resulting excellent high-temperature strength, superior high-temperature volume stability, as well as outstanding corrosion and erosion resistance.

Specifications

| Item | Grade | ||||||||

| DMGe-26 | DMGe-24 | DMGe-22 | DMGe-20A | DMGe-20B | DMGe-16A | DMGe-16B | DMGe-12A | DMGe-12A | |

| ω(MgO) / % | ≥ 50 | ≥ 50 | ≥ 55 | ≥ 58 | ≥ 58 | ≥ 62 | ≥ 58 | ≥ 68 | ≥ 65 |

| ω(Cr2O3) / % | ≥ 26 | ≥ 24 | ≥ 22 | ≥ 20 | ≥ 20 | ≥ 16 | ≥ 16 | ≥ 12 | ≥ 12 |

| ω(SiO₂) / % | ≤ 1.5 | ≤ 1.5 | ≤ 1.5 | ≤ 1.5 | ≤ 2.0 | ≤ 1.5 | ≤ 2.0 | ≤ 1.5 | ≤ 2.0 |

| Open Porosity / % | ≤ 16(15) | ≤ 16(15) | ≤ 16(15) | ≤ 16(15) | ≤ 17(15) | ≤ 16(15) | ≤ 17(16) | ≤ 16(15) | ≤ 17(16) |

| CCS / MPa | ≥ 40(45) | ≥ 40(45) | ≥ 40(45) | ≥ 40(45) | ≥ 40(45) | ≥ 40(45) | ≥ 40(45) | ≥ 40(45) | ≥ 40(45) |

| min35(40) | min35(40) | min35(40) | min35(40) | min35(40) | min35(40) | min35(40) | min35(40) | min35(40) | |

| R.U.L / 0.2 MPa T0.6/℃ | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 |

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

Applications

Widely used in the slag line areas of non-ferrous metallurgical furnaces, tuyere zone of heavy non-ferrous metal converters, critical areas of flash furnaces, side-blown furnaces, and Isasmelt furnaces, high-temperature zone of basic refractory kilns, steel-making RH furnaces,etc.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.