Description

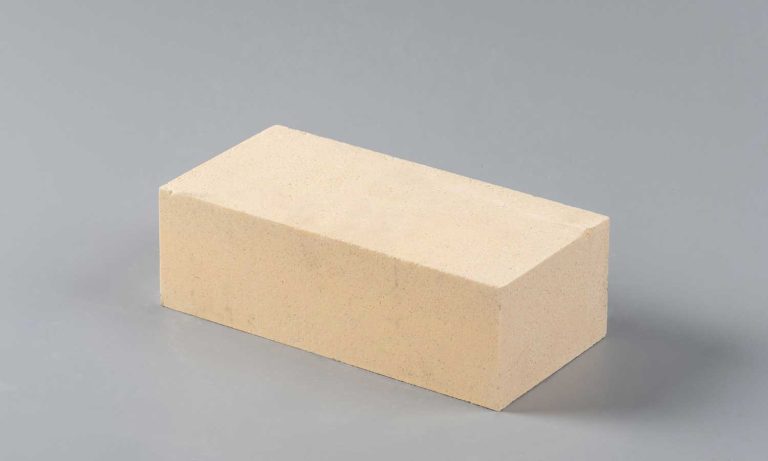

Dense zircon bricks are high-performance refractory bricks made from zircon sand raw materials after extrusion molding and high-temperature calcination process.

Dense zircon bricks have extremely high density and low porosity, which makes them have excellent erosion resistance and can effectively resist the erosion of high-temperature melts and slag.

Dense zircon bricks have high volume density and high strength. They can still maintain good structural stability in high temperature environments .

In addition, dense zircon bricks also have good refractoriness and thermal shock stability, withstanding high temperature fluctuations without cracking.

Specifications

| Items | Grades | |||||

| ZS-G | ZS-Z | ZS-65A | ZS-65B | ZS-63 | ||

| Density / (g/cm3) | ≥4.30 | ≥4.10 | ≥3.70 | ≥3.60 | ≥3.55 | |

| Open Porosity / % | ≤1 | ≤11 | ≤17 | ≤19 | ≤20 | |

| CCS / MPa | ≥300 | ≥200 | ≥100 | ≥80 | ≥60 | |

| R.U.L (0.2 MPa ,T0.6) / ℃ | ≥1700 | ≥1700 | ≥1680 | ≥1650 | ≥1600 | |

| Element | ZrO2 | ≥65 | ≥68 | ≥65 | ≥63 | |

| SiO2 | ≤33 | ≤30 | ≤33 | ≤35 | ||

| Fe2O3 | ≤0.20 | ≤0.20 | ≤0.20 | ≤0.20 | ||

| TiO2 | ≤1.20 | ≤1.20 | ≤1.20 | —— | ||

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

Applications

Dense zircon bricks have important uses in many industrial fields due to their excellent performance.

In the glass industry, dense zircon bricks are often used for the pool walls of special glass melting furnaces, which can resist the erosion of glass liquid and ensure the quality of glass and the service life of the melting furnace.

In the ceramic field, dense zircon bricks can be used as lining materials for kilns to provide a stable high-temperature environment and reduce heat loss.

In some chemical equipment that requires high temperature resistance and corrosion resistance, dense zircon bricks are also used as lining materials to resist the erosion of various chemical substances and ensure the normal operation of the equipment.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.