Description:

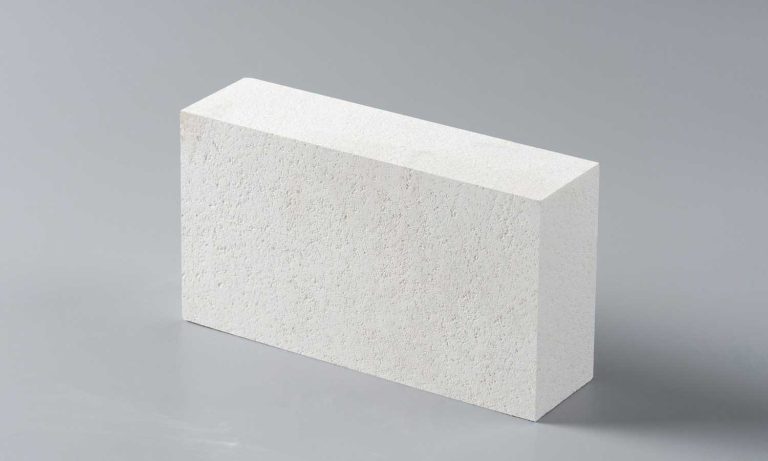

Corundum brick is an excellent refractory brick with corundum as the main crystal phase and Al2O3 content of more than 95%. It is made of industrial alumina or high-alumina bauxite as the main raw material and is formed by high-temperature sintering.

The refractory temperature of corundum bricks can reach above 1770℃, and they have good thermal shock stability, and can remain stable in the case of rapid temperature changes.

In addition, corundum bricks have the characteristics of high mechanical strength and good wear resistance, and can resist material erosion and wear.

Excellent chemical stability makes it have excellent corrosion resistance and can resist the corrosion of various chemical substances.

Specifications

| Items | Grades | ||||

| GYZ-99A | GYZ-99B | GYZ-98 | GYZ-95 | ||

| ω(Al2O3) / % | μ0 | ≥99.0 | ≥99.0 | ≥98.0 | ≥95.0 |

| ω(SiO2) / % | μ0 | ≤0.15 | ≤0.2 | ≤0.5 | —— |

| ω(Fe2O3) / % | μ0 | ≤0.10 | ≤0.15 | ≤0.20 | ≤0.30 |

| Open Porosity / % | μ0 | ≤19 | ≤19 | ≤19 | ≤20 |

| Density / (g/cm3) | μ0 | ≥3.20 | ≥3.15 | ≥3.15 | ≥3.10 |

| CCS / MPa | μ0 | ≥80 | ≥80 | ≥80 | ≥100 |

| HPLC (1600℃×3h) / % | XminXmax | -0.2~+0.2 | -0.2~+0.2 | -0.2~+0.2 | -0.3~+0.3 |

| R.U.L (0.2 MPa ,0.6%) / ℃ | Xmin | 1700 | 1700 | 1700 | 1700 |

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

Applications

In the metallurgical industry, Corundum bricks are used for linings of blast furnaces, electric furnaces, converters, etc., and can withstand the erosion of high temperature molten iron and slag.

In the glass industry, they can be used as refractory materials for key parts of glass melting furnaces.

In the ceramic field, they are important furnace building materials for ceramic kilns, which can ensure the stability of the high temperature environment in the kiln;

In addition, in the chemical and building materials industries, corundum bricks also play their advantages of high temperature resistance and corrosion resistance to ensure the efficient operation of equipment.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.