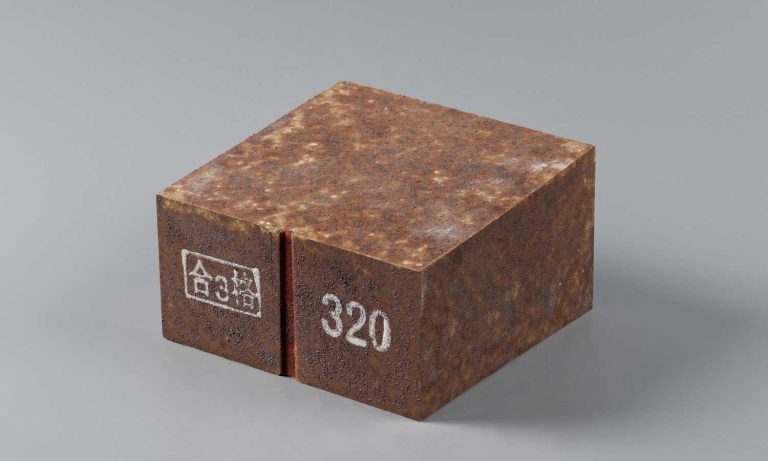

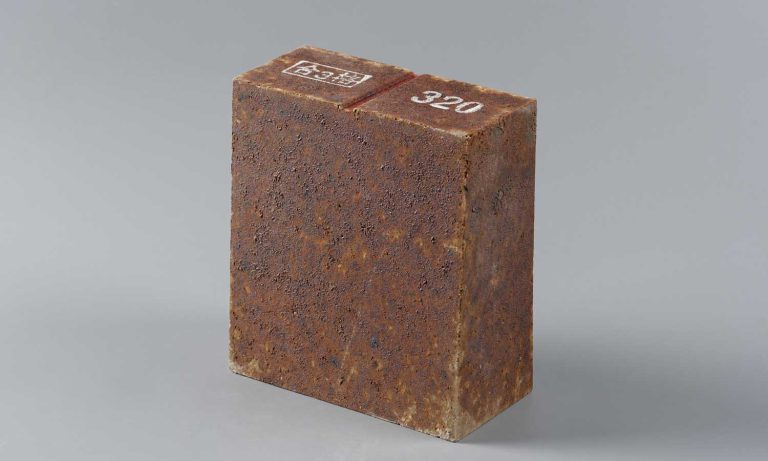

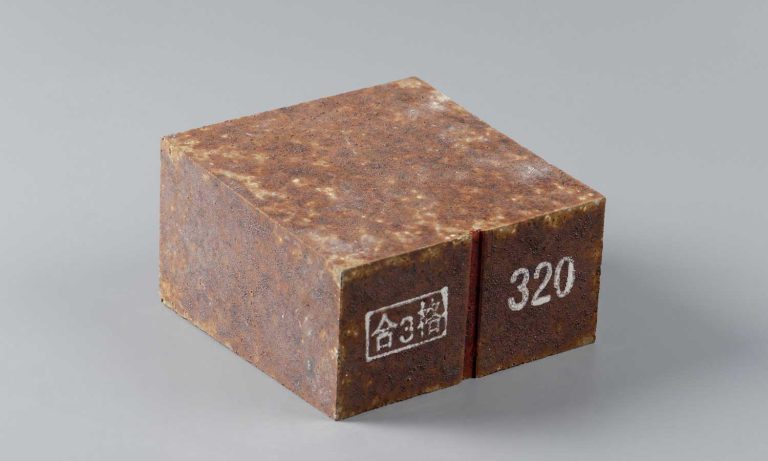

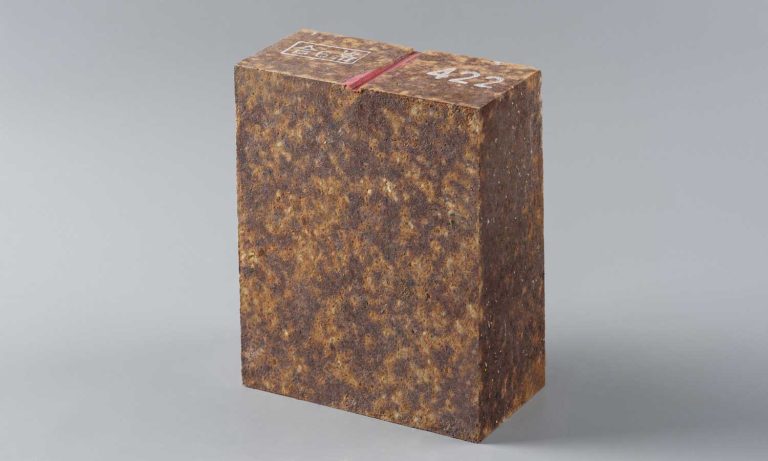

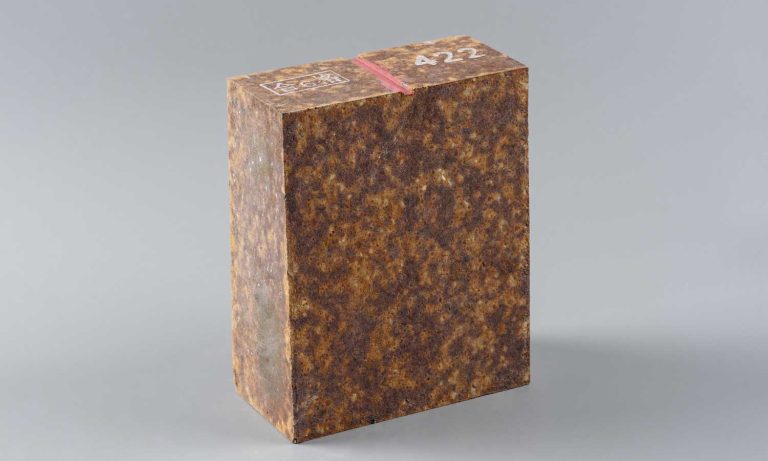

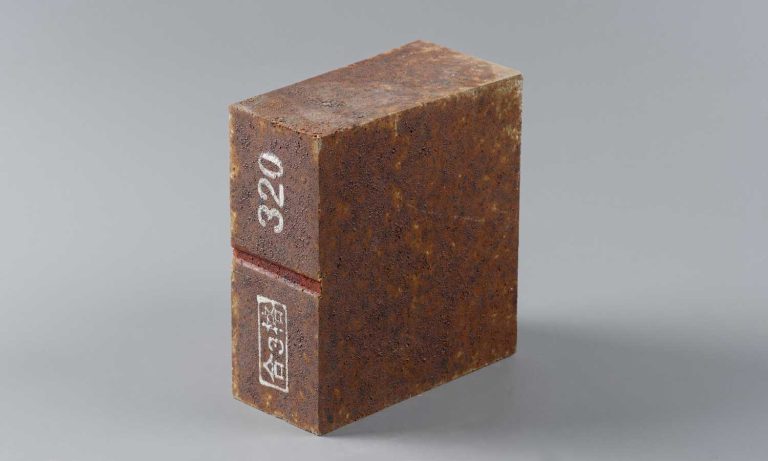

Description

High alumina silicon carbide brick refers to a high-performance refractory material made primarily from high alumina bauxite and silicon carbide. It features a high refractoriness and good thermal conductivity, high-temperature strength and thermal shock resistance.

Advantages: Al2O3 withstand high temperature above 1700℃, SiC has excellent resistance to slag, molten metal and alkali corrosion, good thermal shock stability, high thermal conductivity, high mechanical strength and wear resistance.

Related Products

Phosphate bonded alumina bricks: high refractories, low porosity, thermal shock resistance, good wear resistance, more>

Alumina SiC Carbon Bricks: High load-bearing strength at high temperatures, excellent thermal shock resistance, more>

Silicon carbide low cement castable: excellent strength and wear resistance, good corrosion resistance, more>

Specification

| Item | Grades | ||

| GM1 650 | GM1 600 | GM1550 | |

| Al2O3/%≥ | 65 | 63 | 60 |

| SiC/%≥ | 5 | 5 | 5 |

| Bulk Density / (g/cm3)≥ | 2.65 | 2.60 | 2.55 |

| Open Porosity /%≤ | 17 | 17 | 19 |

| CCS/MPa≥ | 85 | 90 | 90 |

| 0.2 MPa R.U.L T0.6/℃≥ | 1650 | 1600 | 1550 |

| TSR(1100℃, Cold Water) / cycles≥ | 10 | 10 | 12 |

| Abrasive Resistance/cm3≥ | 5 | ||

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

Applications

Mainly used in the transition zone and cooling zone of cement rotary kilns, as well as in lime kilns. Also be applied in non-ferrous metal smelting furnaces, waste incinerators, and fluidized bed boilers.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.