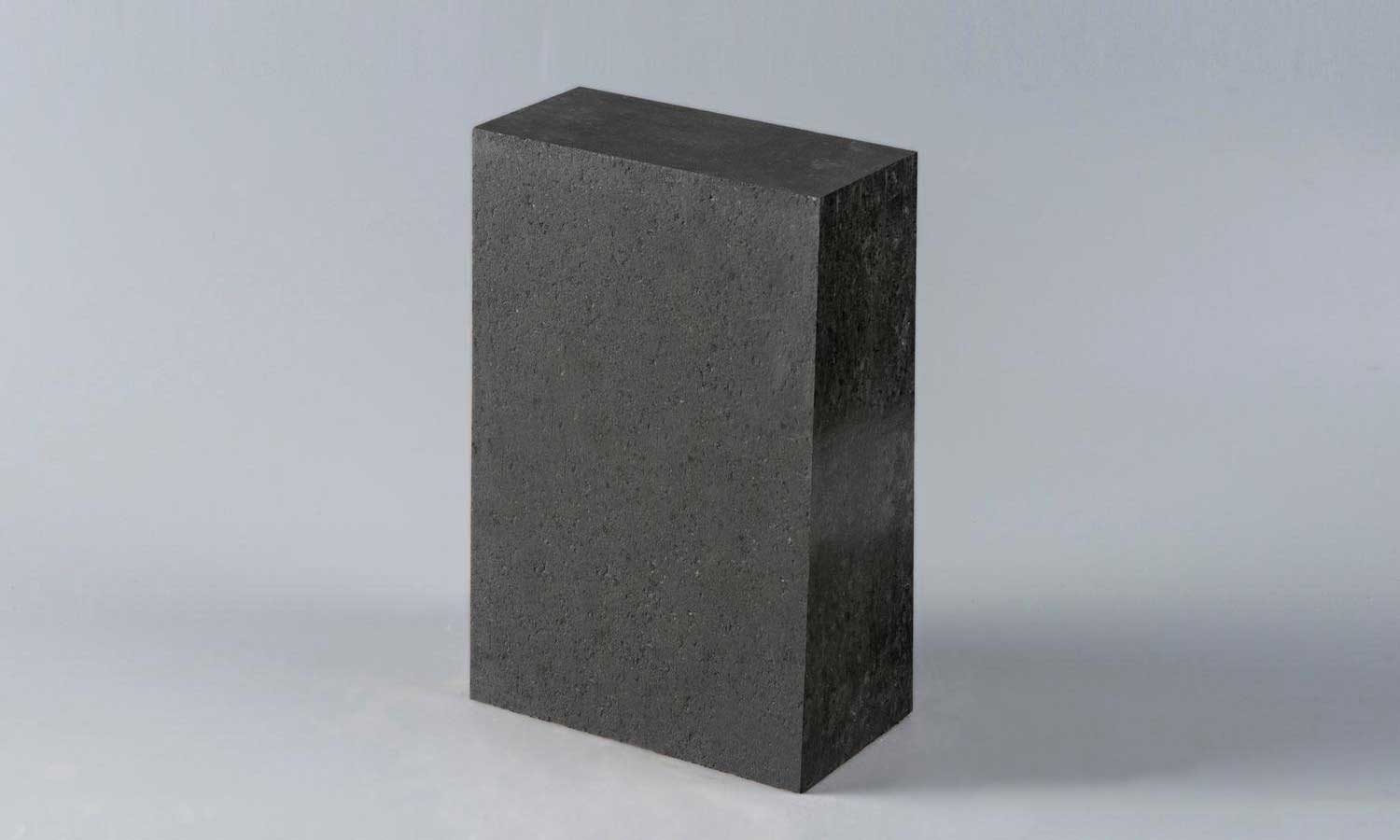

Description

Alumina magnesia ramming mass is a kind of amorphous refractory material used in metallurgy and other industries. It is made of alumina and magnesia as the main raw materials, with appropriate amount of binder and additives added.

Alumina magnesia ramming mass has good refractoriness, thermal shock resistance and erosion resistance, withstanding the scouring and erosion of high temperature melt. It can be used on the lining of equipment of different shapes with ramming method.

Specifications

| Items | Grades | ||||

| AMD-95 | AMD-85 | AMD-80 | AMD-70 | ||

| ω(Al2O3+MgO) / % | ≥95 | ≥85 | ≥80 | ≥70 | |

| ω(MgO) / % | ≥2 | ≥5 | ≥8 | ≥10 | |

| Density / (g/cm³) | 110℃×24h | ≥3.0 | ≥2.8 | ≥2.75 | ≥2.55 |

| CCS / MPa | 110℃×24h | ≥35 | ≥35 | ≥35 | ≥35 |

| 1000℃×3h | ≥40 | ≥40 | ≥40 | ≥40 | |

| —— | ≥601600℃×3h | ≥501550℃×3h | ≥301550℃×3h | ≥301500℃×3h | |

| CMOR / MPa | 110℃×24h | ≥6 | ≥4 | ≥4 | ≥4 |

| 1000℃×3h | ≥8 | ≥6 | ≥4 | ≥4 | |

| —— | ≥101600℃×3h | ≥61550℃×3h | ≥41550℃×3h | ≥31500℃×3h | |

| HPLC / % | 0~+1.51600℃×3h | 0~+2.01550℃×3h | 0~+2.01550℃×3h | 0~+2.01500℃×3h | |

Product Size: We offer refractory brick sizes that comply with ISO, EN, ASTM, JIS, etc, and customized sizes.

Applications

Alumina magnesia ramming mass is mainly used for the lining of thermal equipment such as blast furnaces, electric furnaces, converters in the metallurgical industry. Alumina magnesia ramming mass is also used in non-ferrous metal smelting furnaces, glass kilns, etc. They can withstand high temperatures, scouring and erosion, and play a role in protecting equipment and extending its service life.

Our services: refractory technicians, refractory installation drawings, refractory bricks and castables, refractory masonry services, refractory mixes and precast cell, special shaped bricks, insulation materials, installation supervision, accident investigation and resolution, other customized services.