Quality at JHY Ref: A Culture, Not Just a System

At JHY Ref , quality is not merely a management system, but a core philosophy deeply embedded in our corporate culture and technological innovation. From product research and development to manufacturing control, we uphold rigorous standards at every step to ensure that each technological achievement is transformed into a high-performance product trusted by our customers.

1. Technological innovation drives quality upgrading

We regard innovation as the core driving force of our quality strategy and have a research and development team composed of over 20 senior engineers, dedicated to the development of high-performance refractory materials. Annual R&D investment accounts for 10% of revenue, facilitating continuous technological upgrades.

The R&D center is equipped with a high-temperature simulation laboratory and various advanced testing equipment, providing a guarantee for material breakthroughs

It has accumulated over 40 patents and possesses profound technical strength. We have long-term cooperation with many universities to jointly build cutting-edge scientific research projects. Focus on developing sustainable and long-life new refractory technologies to meet the future demands of industrial development.

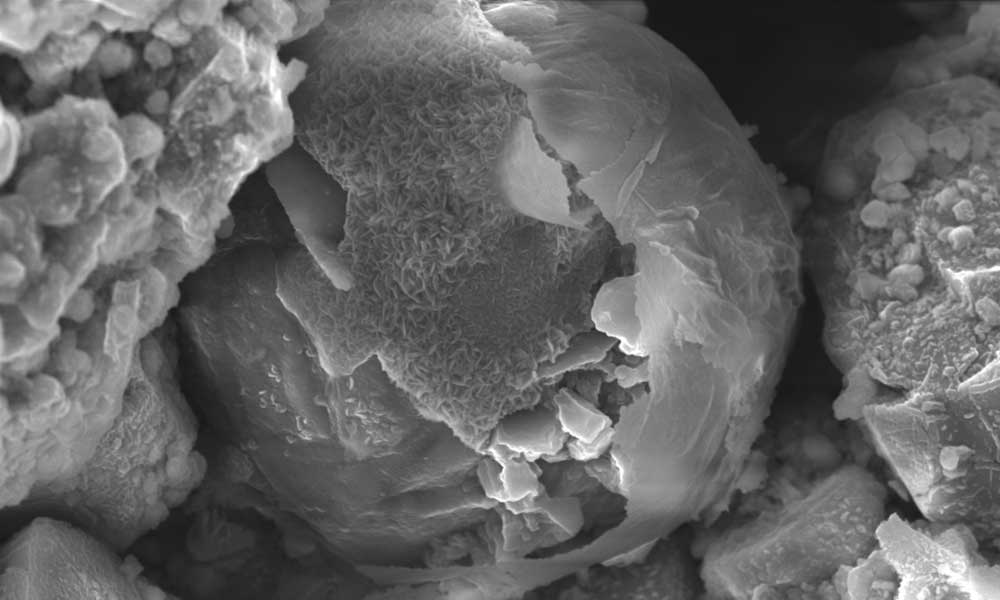

2. Strict Raw Material Control

We believe quality starts with raw materials. We maintain strategic partnerships with certified suppliers and enforce rigorous qualification audits to ensure stable and traceable sourcing.

For critical raw materials such as bauxite and magnesia, we pursue vertical integration, securing upstream resources and supply chain consistency. All raw materials must pass multiple tests such as chemical composition, particle size and moisture content before entering the factory, and strict acceptance standards must be implemented to ensure stable quality.

3. Smart Manufacturing for Precise Delivery

Our manufacturing is driven by automation, traceability, and intelligent control. Powered by our self-developed IMSDO digital platform, we monitor every stage—from batching to production to final delivery—while also tracking carbon emissions in real time.

Our factories are fully integrated with digital systems and automated lines, ensuring consistent quality and high operational efficiency.

4. Comprehensive Testing & Quality Assurance

Every product undergoes rigorous testing to ensure compliance with global standards. Key performance metrics include bulk density, softening under load, apparent porosity, RUL, and thermal shock resistance. Testing procedures strictly follow international standards such as ISO, ASTM, and EN. Upon request, we provide detailed batch-specific testing reports to build transparency and customer trust.

5. Full life-cycle and on-site Technical Support

We offer comprehensive, end-to-end technical support—from installation to maintenance. Our experienced field engineers work closely with clients on-site, providing installation guidance, performance diagnostics, and process optimization. This support minimizes downtime, extends refractory service life, and enhances overall plant efficiency.

The hands-on data collected during these service interactions also feeds back into our R&D, driving continuous improvement based on real-world application scenarios.

6. Commitment to Sustainable Development

Sustainability is embedded in every step of our production. We continuously reduce environmental impact through formula optimization and cleaner manufacturing processes. Our IMSDO intelligent system enables real-time tracking of carbon emissions throughout the production lifecycle.

In R&D, we prioritize the development of eco-friendly, long-lasting refractory solutions to accelerate the green transformation of high-temperature industries.