Zinc oxide rotary kilns use castable refractories at the kiln inlet and outlet, with a length of 80-100 cm and thickness of 20-50 cm. The shape is typically tapered. After installing the refractory bricks inside the kiln and the castables at the inlet and outlet, workers must bake the refractory materials before feeding raw materials into the kiln.

The Importance of Baking Zinc Oxide Rotary Kilns

As the core equipment in zinc oxide production, the rotary kiln’s operational stability and service life directly affect production efficiency, product quality, and production costs. Kiln baking is a critical process before the zinc oxide rotary kiln starts production or after maintenance. This process plays an important role in ensuring the equipment’s safe operation and meeting production standards.

Why Bake Zinc Oxide Rotary Kilns?

The kiln inlet and outlet use castable refractories. These castables are mostly bonded with cement. Workers add water, then mix, vibrate, and cure the material. If the temperature rises directly to high levels without baking, the moisture inside the castables will vaporize rapidly. The volume expands dramatically (water expands about 1700 times when it turns into steam). This creates enormous internal stress within the lining, causing the castables to crack or even explode.

How to Bake Zinc Oxide Rotary Kilns?

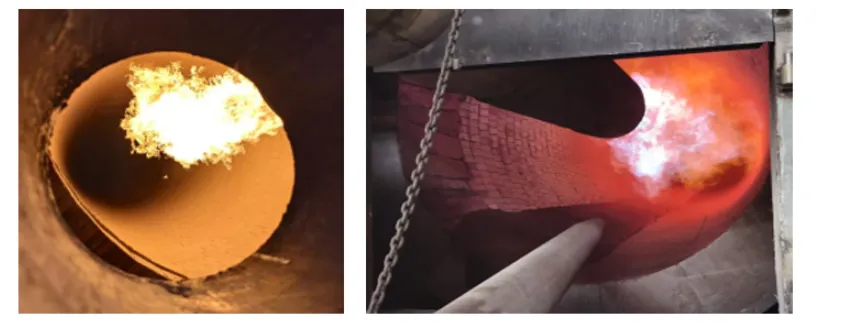

1)Wood-Firing Baking

For factories without natural gas or pulverized coal burners, they can use the wood-firing baking method. The image above shows wood-firing baking. First, workers place firewood at the kiln outlet, about 1 meter away from the outlet castables. The firewood height should be one-third of the kiln diameter. After igniting the firewood, workers quickly exit the rotary kiln. When the firewood burns out naturally, they rotate the kiln by one-quarter turn and ignite firewood again using the same method. After three rotations, the baking of the entire kiln outlet castables is complete. Workers use this same method to bake the kiln inlet castables.

This method has drawbacks. The baking of inlet and outlet castables is not very uniform. The chemically bound water inside the castables may not fully evaporate.

2)Burner Baking

Factories with burners can use them for baking. When using burners (firing natural gas or pulverized coal) for baking, this method effectively avoids the uneven baking problem of wood-firing. Additionally, workers can adjust the baking time, which helps remove the chemically bound water inside the castables more effectively.

Precautions for Zinc Oxide Rotary Kiln Baking

·Workers must strictly follow the required kiln baking temperature and holding time. They must not arbitrarily increase the baking temperature or speed up or shorten the baking time.

·During kiln baking, operators should stay at their posts and monitor instrument readings closely. They must not operate at will.

·During kiln baking, workers should frequently inspect the conditions (visual inspection). They must report any abnormalities immediately.

·During kiln baking, workers should record the flue gas temperature once every hour.

·Kiln baking must ensure that water vapor can escape freely throughout the process.

Common Problems During Zinc Oxide Rotary Kiln Baking

Workers must strictly follow the baking temperature schedule and kiln baking principles during the process. Throughout the entire kiln baking process, they should follow the principle of “slow heating, steady rise, no retreat.” Temperature drops or local overheating are not permitted. If the baking schedule is incorrect or the baking temperature is wrong, the castables will crack or explode.

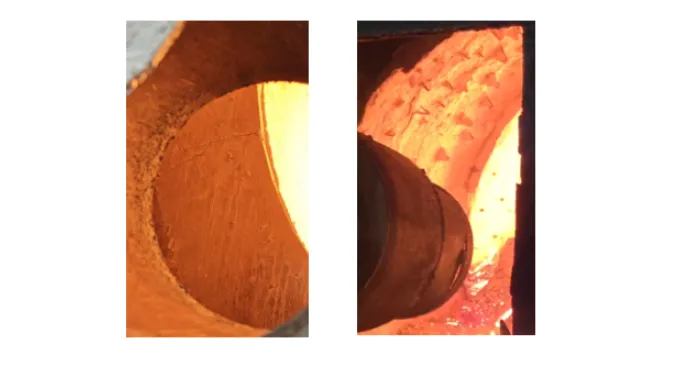

As shown in the figure above, the left image shows minor cracking of the castables. The main reason is that the minimum temperature during burner baking is too high. Under normal conditions, the castables need to be held at around 110°C for more than 24 hours. However, during burner baking, the hot face temperature of the castables is at least 200°C or above. When the chemically bound water inside turns into steam, the internal vapor pressure causes the castables to crack.

In the right image, the castables almost completely fell off shortly after the rotary kiln started feeding. The main reason is excessively rapid heating. This causes the moisture inside the castables to quickly turn into steam, and the volume expands dramatically. The internal saturated vapor pressure exceeds the tensile strength of the castables, causing them to shatter from the inside.