Magnesia chrome bricks come in three main types based on their manufacturing process: direct bonded, fused semi-rebonded, and fused rebonded. Each type has distinct characteristics that make it suitable for specific industrial applications.

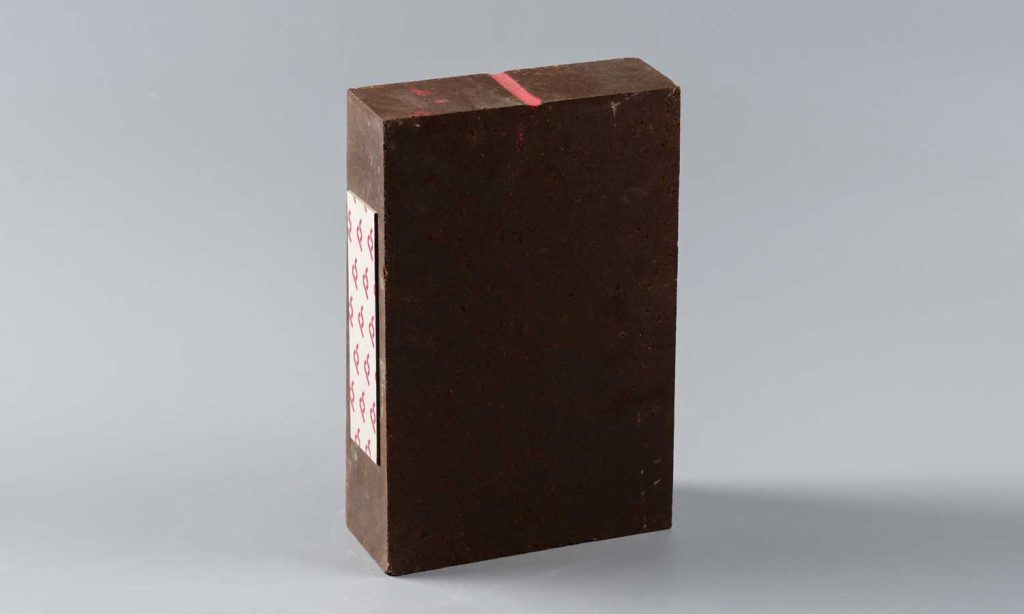

Direct Bonded Magnesia-Chrome Brick

Direct bonded magnesia-chrome brick is a refractory product composed primarily of periclase and magnesia-chromite spinel with direct bonding between grains. The brick is made from high-purity sintered magnesia containing less than 2% SiO₂ and chromite, produced through high-temperature sintering.

The product has low impurity content and undergoes firing at high and ultra-high temperatures. This creates low porosity and high compressive strength. The bricks also exhibit excellent wear resistance, corrosion resistance, thermal shock resistance, and spalling resistance.

Application

Direct bonded magnesia-chrome bricks work well in critical areas across metallurgy, cement, and non-ferrous metal industries. They perform effectively in the slag line and severely corroded areas of secondary refining furnaces. In cement production, they handle the demanding conditions in the transition zone and burning zone of rotary kilns. Glass manufacturers also rely on them in furnace regenerators.

Fused Semi-Rebonded Magnesia-Chrome Brick

Fused semi-rebonded magnesia-chrome bricks combine fused magnesia-chrome spinel, high-purity magnesia, high-purity chrome concentrate, and a composite high-temperature toughening agent. The manufacturing process involves high-pressure forming followed by high-temperature sintering.

These bricks deliver excellent high-temperature performance and thermal stability. They also provide high mechanical strength, superior corrosion resistance, and outstanding anti-spalling performance.

Application

Fused semi-rebonded magnesia-chrome bricks serve critical areas in metallurgy, cement, and non-ferrous metal industries. They excel in slag lines and severely corroded areas of secondary refining furnaces. The bricks also perform well in the transition zone and burning zone of cement rotary kilns, as well as in glass furnace regenerators.

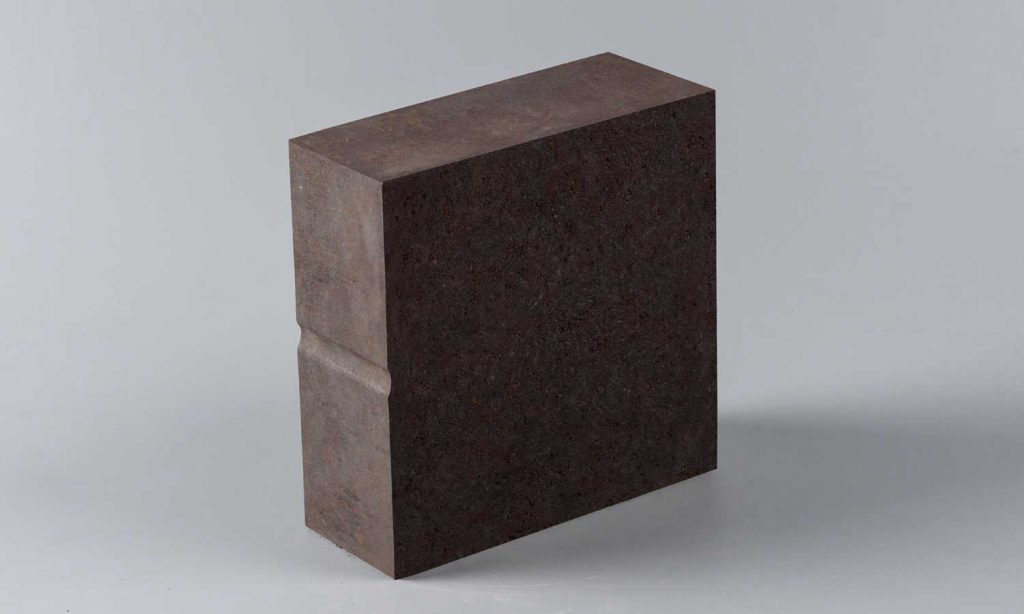

Fused Rebonded Magnesia-Chrome Brick

Fused rebonded magnesia-chrome brick starts with melting lightly burned magnesia and chromite in an electric arc furnace to produce fused magnesia-chrome sand. The sand is then crushed, ground, proportioned, shaped, and sintered to create the final product.

These bricks achieve a high degree of direct bonding with low impurity content. This translates to excellent high-temperature strength, superior high-temperature volume stability, and outstanding corrosion and erosion resistance.

Application

Fused rebonded magnesia-chrome bricks handle the most demanding industrial conditions. They work effectively in slag line areas of non-ferrous metallurgical furnaces and in the tuyere zone of heavy non-ferrous metal converters. These bricks also serve critical areas of flash furnaces, side-blown furnaces, and Isasmelt furnaces. Steel plants use them in the high-temperature zones of basic refractory kilns and RH furnaces.

Conclusion

The three types of magnesia chrome bricks—direct bonded, fused semi-rebonded, and fused rebonded—each offer specific advantages based on their manufacturing process and resulting properties. Understanding these differences helps in selecting the right brick type for particular operational requirements.