The chemical formula of magnesia alumina spinel is MgAl2O4, and the theoretical chemical composition is 28.2% magnesia (MgO) and 71.8% alumina (Al2O3), the molar ratio of magnesium oxide to aluminum oxide is 1:1.

The magnesia content in magnesia alumina spinel bricks is different, and the performance and application scenarios of refractory bricks are also different. Compared with magnesia alumina spinel bricks with a magnesia content of 85%, the bricks with a magnesia content of 80% have the following advantages:

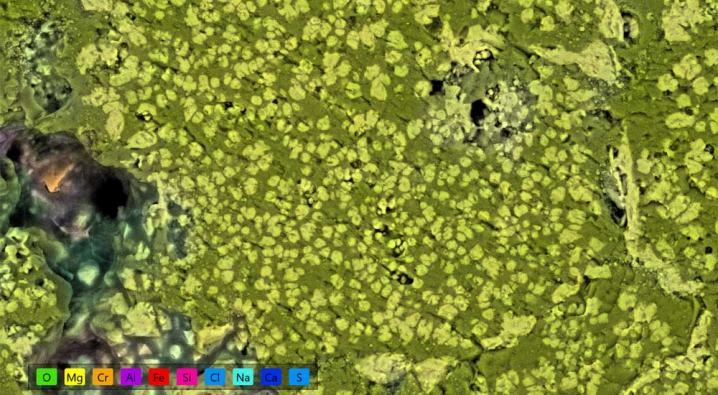

Better thermal shock resistance: Refractory bricks with 80% magnesia content mean a higher content of spinel phase (MgAl2O4) (usually 15% – 20% or more), and a correspondingly lower content of periclase phase. The thermal expansion coefficient of spinel (7.6×10–⁶/K) is much lower than that of periclase (13.5×10–⁶/K). A higher spinel content means:

- The lower thermal expansion coefficient of the refractory brick.

- The periclase grains are wrapped or isolated by more continuous spinel phases, reducing the direct contact between the periclase grains.

- When the temp changes suddenly, the smaller micro stress generated by the expansion/contraction difference between different crystal phases (periclase – spinel).

- The spinel phase and the micro crack network it forms can better absorb and dissipate thermal stress.

- The thermal shock resistance (cold water ~ 1100 ℃) of magnesia alumina spinel bricks with a MgO content of 80% is usually greater than 12 cycles, while the thermal shock resistance (cold water ~ 1100 ℃) of magnesia alumina spinel bricks with a MgO content of 85% is usually greater than 8 cycles.

Better resistance to alkaline erosion:

- The spinel phase (MgAl2O4) has strong chemical resistance to alkali metal oxides (K2O, Na2O) and sulfates.

- The silicate phase at the periclase grain boundary is wrapped and protected by the denser spinel phase.

- It is more difficult for alkali vapor and molten alkali salt to penetrate into the interior of the brick. Even if a small amount of alkali invades, it is more difficult to react destructively with the main crystal phase and generate low-melting products (such as potassium nephrite).

Improved resistance to slag penetration (especially for high FeO/MnO slag):

- The dust collected from blast furnaces and converters contains a large amount of FeO, MnO and other oxides, and the spinel phase has poor wettability with slag containing FeO/MnO and other oxides.

- Spinel can effectively “capture” FeO/MnO to form a high-melting-point solid solution, preventing it from further penetrating into the interior of the brick, and then reacting with periclase to form a low-melting-point substance.

Lower thermal conductivity: The thermal conductivity of the spinel phase (15 W/m·K) is lower than that of periclase (40 W/m·K). A higher spinel content will slightly reduce the overall thermal conductivity of the material, making the rotary kiln more energy-efficient.

Magnesia alumina spinel bricks with 85% magnesia content are more suitable for the following working conditions: high temperature mechanical wear, extreme high temperature or high calcium alkaline slag erosion, thermal shock and alkali erosion are relatively not serious. Typical application: the rear part of the cement kiln firing zone.

As the magnesia content decreases and the alumina content increases, the refractoriness under load of the refractory brick will decrease. The melting point of corundum is much lower than that of periclase phase. The melting point of periclase (MgO) is 2852℃, and the melting point of corundum (Al2O3) is 2072℃.

The refractoriness under load (0.2Mpa/T0.6) of magnesia alumina spinel brick with a magnesia content of 75% is greater than 1650℃, while the refractoriness under load (0.2Mpa/T0.6) of magnesia alumina spinel brick with a magnesia oxide content of 80% and 85% is greater than 1700℃

Magnesia alumina spinel bricks with 80% magnesia content have more spinel phases, and have significant performance advantages over magnesia-rich magnesia alumina spinel bricks with 85% magnesia content in terms of thermal shock stability, alkaline erosion resistance, and resistance to high iron slag penetration.

These advantages make it the preferred long-life refractory brick material for industrial kilns (especially high temperature zones of rotary kilns for zinc oxide recycle from metallurgy solid waste) that withstand high temperature changes and high-alkali environments.