In modern high-temperature industries, energy efficiency and operational safety have long been major challenges faced by enterprises. Traditional insulation materials can meet basic requirements to some extent; however,with the continuous advancement of industrial technologies, their limitations have become increasingly evident. As a new generation of thermal insulation material, nano microporous insulation boards, with their outstanding performance and broad application potential, are rapidly emerging as a preferred solution for high-temperature industrial applications.

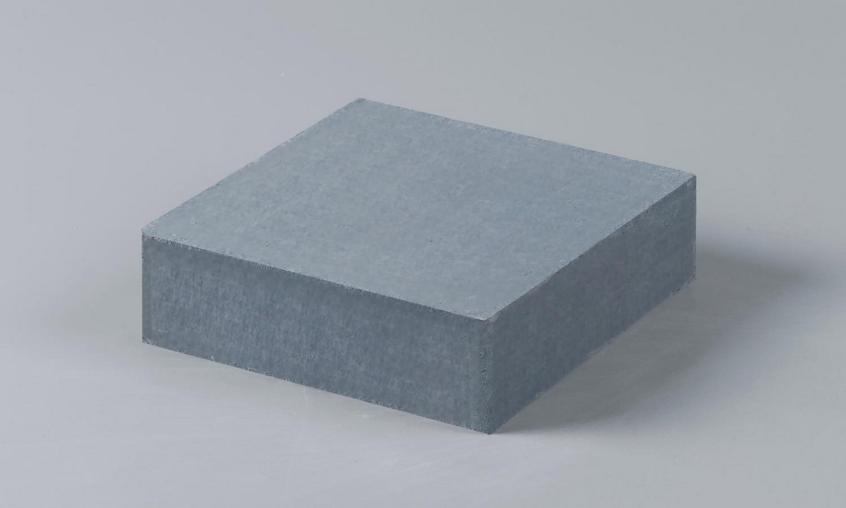

What is a Nano Microporous Insulation Board?

The nano microporous insulation board is manufactured from specially engineered inorganic refractory nano-powders using a patented dry-forming process.Its finely controlled nano-scale pore structure delivers an exceptionally low thermal conductivity—lower than that of still air—while maintaining excellent insulation performance and long-term stability under high-temperature operating conditions.This material serves as a key energy-saving component in modern high-temperature industrial furnace upgrades.

Why Nano Microporous Insulation Board Outperforms Traditional Insulation?

While conventional materials like mineral wool and calcium silicate have been industry staples, the transition to nanoporous technology offers a significant leap in efficiency. Here is how it solves the limitations of traditional solutions:

1)Maximum Thermal Efficiency with Minimal Thickness Unlike bulky traditional insulation that occupies valuable furnace volume, nano microporous boards achieve a superior k-value (0.02–0.025 W/(m·K)), significantly lower than traditional insulation materials such as mineral wool (0.13–0.2 W/(m·K)) or calcium silicate boards (0.15–0.18 W/(m·K)).

2)Exceptional Durability in Extreme High-Temperatures Traditional fiber-based materials often suffer from shrinkage and powdering over time, leading to thermal bridging. Our nano boards maintain structural integrity up to 1000°C, ensuring long-term thermal protection and reducing the need for frequent maintenance shutdowns.

3)Strategic Energy Decarbonization & ROI In the era of carbon neutrality, nano microporous boards are a game-changer. By reducing heat loss by up to 30% compared to traditional linings, they directly lower fuel consumption and carbon emissions, providing a rapid Return on Investment (ROI) for energy-intensive industries.

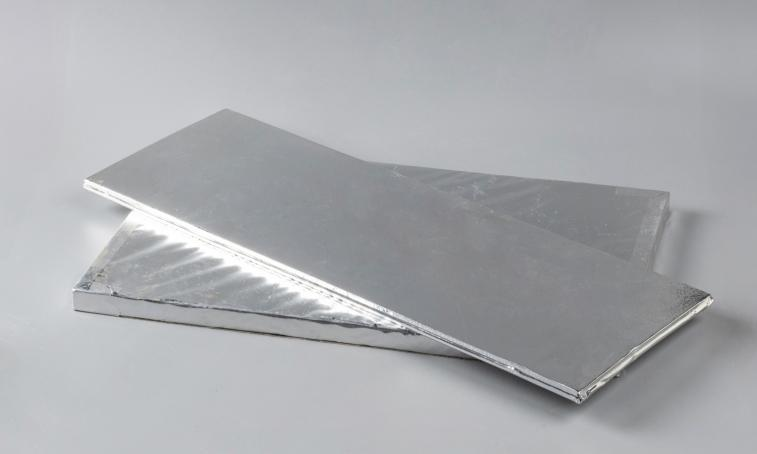

4)Precision Engineering for Complex Industrial Applications Standard rigid insulation often fails at corners or complex joints. Our boards offer strong adaptability and can be precision-tailored to fit intricate geometries—from three-stage air ducts to secondary refining furnaces—ensuring a seamless thermal barrier.

Applications of Nano Microporous Insulation Boards

Cement & Building Materials Industry Applied in three-stage air ducts, preheaters, cooler machines, and decomposers. By utilizing thinner nano-insulation, plants can reduce heat dissipation and optimize the internal airflow volume for better efficiency.

Iron & Steel Metallurgy Critical for iron-clad refractory linings, tundish thermal insulation systems, and the hot-face linings of secondary refining furnaces (LF, RH, VD, etc.). These boards effectively prevent molten steel temperature drops and protect the outer steel shell from thermal fatigue.

Lime & Chemical Kilns Essential for the high-efficiency insulation of preheaters and shaft kilns, ensuring stable internal temperatures and reducing fuel consumption per ton of product.

Aluminum Smelting & Non-Ferrous Metals Optimized for electrolytic cells and thermal insulation assemblies. The boards provide superior chemical resistance and thermal stability in the harsh environments of aluminum reduction.

Waste-to-Energy & Power Generation Used in various high-temperature industrial furnaces and incinerators to maximize steam production efficiency and meet stringent environmental emission standards.

Conclusion

Nano microporous insulation boards are becoming the future trend in high-temperature industrial insulation, gradually replacing traditional insulation materials.If you are seeking high-performance thermal insulation solutions, we invite you to contact Zhengzhou Jinheyuan Refractory Materials Co., Ltd.(JHYRef), where we provide professional technical consultation and customized product solutions.