With the transformation of China’s steel industry from a quantity-based to a quality-focused production mode, as well as increasingly fierce market competition, China’s low-grade steel products and production capacity are in a state of relative surplus, while the proportion of high-quality steel output is less than 10%, and the self-sufficiency rate is seriously insufficient.

In 2020, China imported 20.23 million tons of steel, almost all of which were high-value-added fine steel. With the accelerated upgrading of China’s industrial structure, the demand for various functional fine steels will increase.

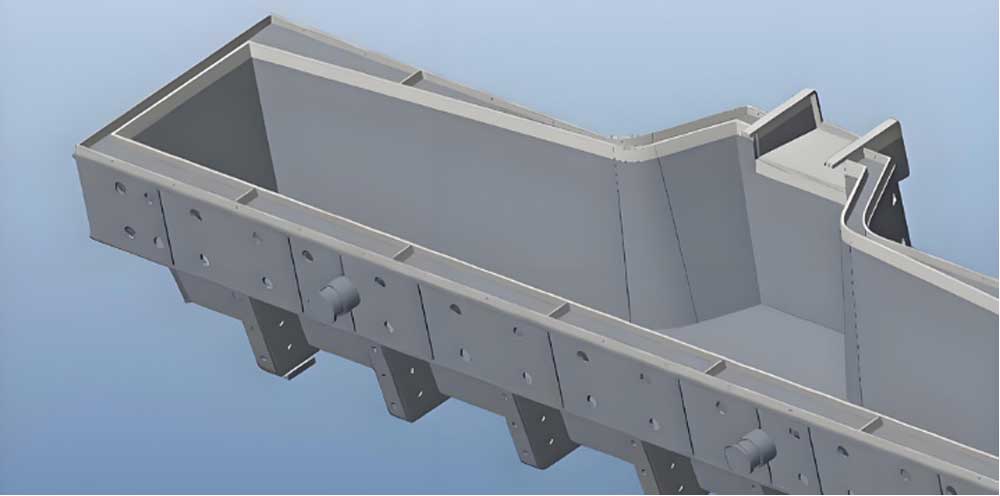

High-quality steel requires that harmful elements such as C, O, N, H, P, and S be controlled at a low level. The tundish is the last important process that affects the quality of molten steel. The impurities released by the refractory dry mix, especially the carbon element in the binder, have a crucial impact on the molten steel.

In view of this situation, it is urgent to develop a dry carbon-free binder to avoid carbon pollution of molten steel. Na2SiO3·9H2O-(NaPO3)6 carbon-free binder has the advantages of high bonding strength, low cost, easy production and storage, and is currently a hot research direction.

We studied the performance of the dry tundish material combined with Na2SiO3·9H2O-(NaPO3)6: including the bulk density, flexural strength, compressive strength, linear change rate and slag resistance, and the analysis of the permeability mechanism. We finally determined the optimal content of Na2SiO3·9H2O and analyzed the erosion mechanism.

The results show that when the content of Na2SiO3·9H2O is 4%, the refractory dry mix exhibits excellent comprehensive performance and can meet the use requirements of on-site working conditions. The slag resistance test shows that this refractory dry mix has good corrosion resistance but poor permeability resistance.

The slag liquid is easy to melt with the liquid after the binder is sintered, and penetrate into the refractory dry mix along the microchannel formed by the liquid phase. Since the mixture of slag liquid and liquid phase distributed in the permeation layer has a high viscosity, a relatively stable immobile layer is formed in the permeation layer, which reduces the driving force of the tundish slag liquid to react inside the refractory dry mix, thereby hindering the reaction process between the clear liquid and the refractory dry mix. Therefore, the refractory dry mix and the slag liquid are easily infiltrated but the degree of erosion is not obvious.