Mullite bricks are high-alumina refractory materials with mullite as the main crystal phase.

Crystal Structure of Mullite Refractory Bricks

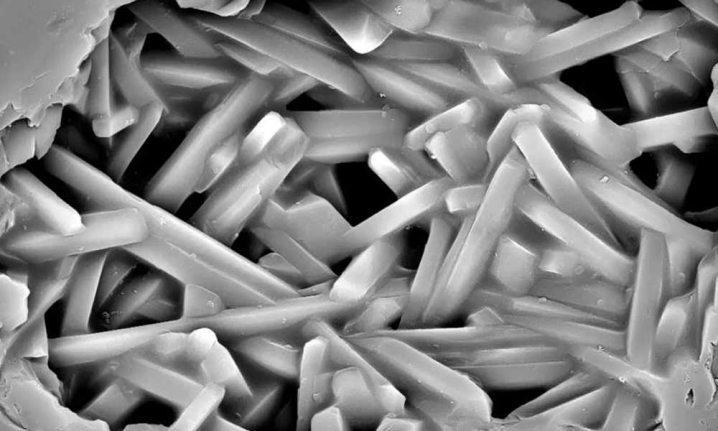

Crystal System and Morphology: mullite crystal belongs to the orthorhombic crystal system. Mullite crystals are columnar or spear – shaped and interlaced. In refractory materials, these acicular mullite crystals interpenetrate with each other to form a solid framework.

Microstructure: mullite brick is composed of double chains formed by the disordered arrangement of silicon – oxygen tetrahedrons (SiO4) and aluminum – oxygen tetrahedrons (AlO4) along the C – axis, and the double chains are connected by aluminum – oxygen octahedrons (AlO6). Along the c – axis direction, it is composed of AlO6 octahedrons sharing edges, and at the same time, it is cross – linked with SiO4 tetrahedrons and AlO4 tetrahedrons by sharing vertices. Therefore, the growth rate of mullite crystals along the c – axis direction is relatively fast, and obvious anisotropic growth is prone to occur.

Main Characteristics of Mullite Refractory Bricks

Excellent High-temp Performance: Mullite bricks have a high refractoriness, reaching over 1790°C, and the initial softening temp under load ranges from 1600°C to 1700°C. They exhibit low high-temp creep deformation and can maintain good structural strength and stability at high temps.

Thermal Shock Resistance: Mullite bricks have a low linear expansion coefficient. Their interlaced acicular crystal structure enables them to withstand rapid temp changes and prevents them from cracking easily due to thermal stress.

Chemical Erosion Resistance: Mullite bricks have better resistance to acidic and low-alkaline molten slags than magnesia-based products. They possess stable chemical properties and are not easily eroded by furnace slags and other substances.

High Mechanical Strength: Mullite bricks have high room-temp compressive strength, generally ranging from 70 MPa to 260 MPa. They can withstand the pressure of materials inside the furnace and mechanical impacts.

Thermal Insulation Performance: Some lightweight mullite insulation bricks feature low thermal conductivity and low heat capacity. They can reduce the volume of the furnace lining masonry, lighten the overall weight, and save energy.