In high temperature industries such as iron and steel production and non-ferrous metal smelting in China, magnesia refractory materials are the most widely used and largest in consumption among basic refractory materials. Their core varieties include magnesia carbon bricks and magnesia alumina bricks (including magnesia alumina spinel bricks).

The Most Commonly Used Basic Refractories in China: Core Varieties and Proportions

In terms of consumption volume in the Chinese market, the order of mainstream varieties is: magnesia carbon bricks (accounting for approximately 40%) > magnesia alumina bricks/magnesia alumina spinel bricks (accounting for approximately 25%), with the remainder being ordinary magnesia bricks, magnesia chrome bricks (gradually phased out), etc. This pattern is mainly determined by the demand of China’s domestic iron and steel industry (the iron and steel industry consumes over 70% of the total basic refractories).

Characteristics and Core Applications of Basic Refractories

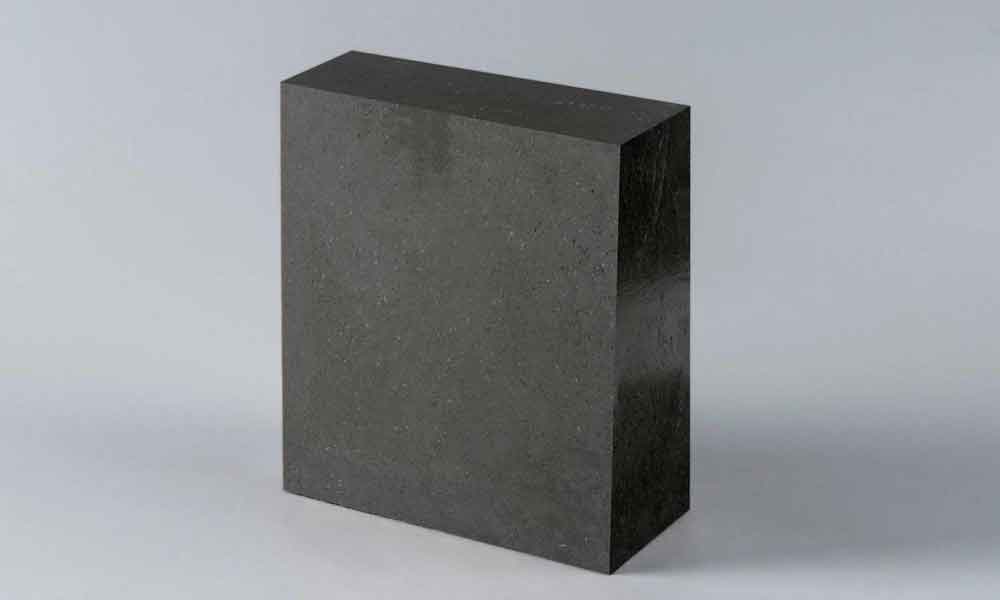

- Magnesia carbon Bricks (The Most Consumed Basic Refractories in China)

Core Components: High-purity MgO (content: 69%-95%) + graphite (content: 5%-18%) + binders such as phenolic resin.

Key Characteristics of Magnesia-carbon Bricks:

- Exceptional resistance to alkaline slag erosion: MgO resists alkaline slag, while the “non-wettability” of graphite prevents slag penetration, resulting in a service life 3-5 times longer than ordinary magnesia bricks.

- Excellent thermal shock resistance: Graphite, with its low thermal expansion coefficient and high thermal conductivity, alleviates thermal stress at high temperatures and reduces material cracking—solving the “easy spalling” issue of ordinary magnesia bricks.

- Good high-temperature strength: It maintains high compressive strength (≥25MPa) even at 1600-1800℃, making it suitable for the “high-load working conditions” of iron and steel smelting.

- Limitations: Graphite is prone to oxidation (requiring antioxidants like Al and Si to be added for protection at high temperatures), and its cost is higher than that of ordinary magnesia bricks.

Main Applications of Magnesia carbon Bricks

Magnesia carbon bricks are fully centered on the “key high-temperature parts” of the iron and steel industry and serve as irreplaceable core materials. Their specific applications include:

- Converter linings (especially the converter body and bottom, accounting for 80% of refractories used in converters).

- Blast furnace hearth and bottom (large blast furnaces mostly adopt a “ceramic cup + magnesia-carbon brick” composite structure to resist molten iron erosion).

- Ladle linings (the slag line and ladle wall of refining ladles, which withstand dual erosion from molten steel and refining slag).

- Electric furnace walls and tapping spouts (high-temperature areas of ultra-high power electric arc furnaces).

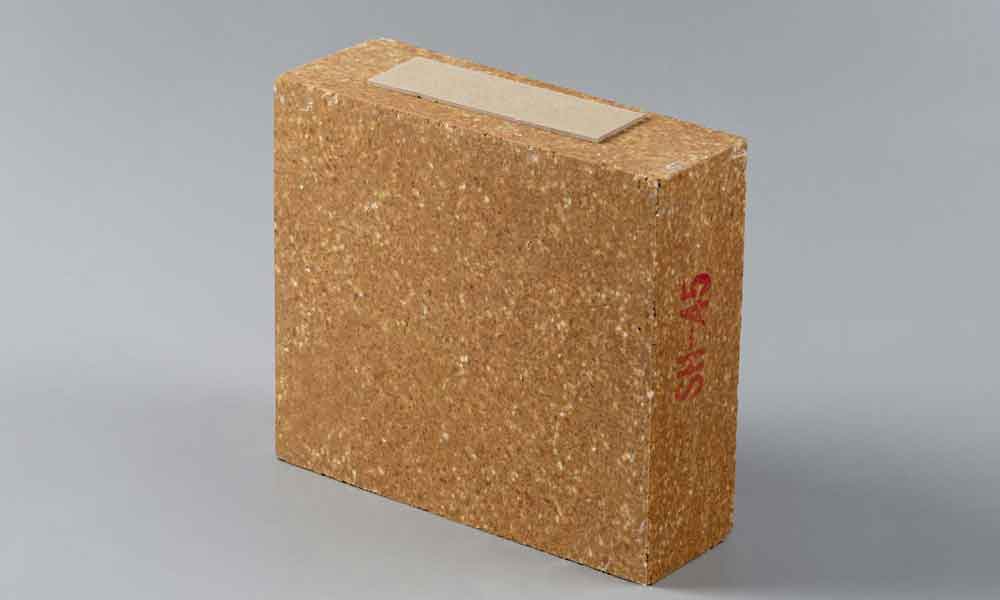

2. Magnesia alumina Bricks / Magnesia alumina Spinel Bricks (Mainstream Varieties Balancing Performance and Cost-effectiveness)

Core Components: MgO (content: 60%-95%) + Al2O3 (content: 15%-40%). Among them, magnesia alumina spinel bricks are materials where magnesia-alumina spinel (MgAl2O4) – formed by the reaction of MgO and Al2O3 at high temperatures – serves as the main bonding phase.

Key Characteristics of Magnesia-alumina Bricks

- Balanced comprehensive performance: They not only retain the alkali resistance of MgO but also significantly improve thermal shock resistance (superior to ordinary magnesia bricks but slightly inferior to magnesia-carbon bricks) and resistance to structural spalling through the incorporation of Al2O3 or spinel.

- Erosion resistance suitable for multiple scenarios: They can resist both alkaline slag and some Al2O3 -containing neutral slag, offering a wider application range than magnesia-carbon bricks.

- High cost-effectiveness: Free of graphite, their raw material cost is 15%-30% lower than that of magnesia-carbon bricks. Additionally, no antioxidants need to be added, and the production process is simpler.

- Limitations: Their resistance to slag penetration is slightly weaker than that of magnesia-carbon bricks, making them unsuitable for converter linings where “slag scouring is extremely intense.”

Main Applications of Magnesia alumina Bricks:

- Magnesia-alumina bricks cover high-temperature scenarios with “non-extreme scouring” – they serve as an important supplement to magnesia-carbon bricks and are also suitable for the cement and non-ferrous metal industries. Their specific applications include:

- Iron and steel industry: Hot blast stoves of blast furnaces (high-temperature heat storage zones that withstand repeated heating and cooling) and tundishes (permanent layers and working layers of continuous casting tundishes).

- Cement industry: Burning zones of rotary kilns (resisting high-temperature erosion from cement clinker, replacing traditional magnesia-chrome bricks) and preheater towers.

- Non-ferrous metal smelting: Linings of copper converters and nickel flash furnaces (replacing chromium-containing materials to reduce pollution).

- Glass industry: Regenerators of glass furnaces (alkaline zones that resist glass slag containing Na₂O).

Application of Basic Refractories in China

Demand is highly dependent on the iron and steel industry: China has ranked first in the world in crude steel output for many consecutive years (with an annual output exceeding 1 billion tons), which determines the core position of basic refractories such as magnesia-carbon bricks and magnesia-alumina bricks. Moreover, demand continues to grow with the construction of “large blast furnaces and ultra-high power converters”.

Environmental protection drives product upgrading: The R&D from “ordinary magnesia-carbon bricks” to “low-graphite / graphite-free magnesia-carbon bricks” is driven by China’s strict environmental protection policies, and environmentally friendly varieties have become the future mainstream.

Cost-effectiveness as a priority: In non-critical parts (e.g., hot blast stoves, cement rotary kilns), magnesia-alumina bricks—with higher cost-effectiveness—still dominate. In critical parts (e.g., converter linings, blast furnace hearths), magnesia-carbon bricks—with superior performance—are the only choice.