The service life of refractory materials in cement kiln linings is influenced at least 40% by construction quality. Even if top-grade materials are selected, improper masonry or casting techniques can still lead to brick spalling, cracking, or flame penetration. The key is to strictly control the three core processes: masonry, casting, and kiln firing.

Practical Methods to Extend the Service Life of Cement Kiln Linings

1.Strict Masonry Standards for Refractory Bricks

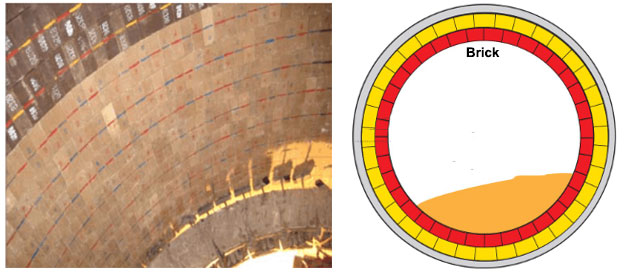

Use the ring-laying method with strict control of brick joints: radial joints in the firing zone ≤1 mm, circumferential joints ≤2 mm, and joints in other kiln sections ≤3 mm. Use specialized refractory mortar for jointing; ordinary cement is strictly prohibited.

Bricks should be laid with staggered joints, keeping the height difference between adjacent bricks ≤0.5 mm and the flatness of each ring ≤2 mm, to prevent material erosion in the joints from forming grooves. In stress-concentrated areas, such as the kiln inlet or riding rings, shaped bricks should be used to avoid cracking caused by straight joint alignment.

Key Brick Locking: The last brick of each ring must be mechanically wedged; manual hammering is strictly prohibited, as it can cause internal cracking. Locking bricks should be evenly distributed, with one set placed every 3–5 rings.

2. Standardized Casting Process for Castables

Before casting, clean the construction surface and weld heat-resistant steel fiber anchors. Choose appropriate welding rods for the kiln, and ensure full welds on the anchors.

Castables must be mixed with water strictly according to the specified ratio, with proper mixing time. After achieving a uniform mix, cast in layers with vibration (vibration rod insertion depth ≤500 mm), ensuring no air bubbles or honeycombing.

After casting, maintain moisture curing at room temperature for 24–48 hours; premature form removal is strictly prohibited.

During winter construction, use auxiliary equipment to raise the kiln temperature, maintaining a minimum suitable temperature of 15 °C.

After demolding, follow a scientifically designed firing curve for kiln baking; otherwise, the lining is prone to cracking, spalling, or bursting.

3.Proper Operating Practices

Improper Operating Practices Are the Primary Cause of Abnormal Lining Wear.Frequent kiln starts and stops, sudden temperature fluctuations, falling kiln coatings, and aggressive cleaning of kiln crusts can subject refractory materials to stresses and erosion far beyond their design limits. Proper operating practices can increase the service life of the lining by more than 30%.

4.Use More Suitable Refractory Materials

Typically, the kiln inlet of a cement kiln is protected using a combination of kiln mouth refractory castables and protective iron. With this method, the service life of the inlet castables is at most one year. However, if steel-fiber prefabricated components are used, the service life of the refractory materials in this area can be doubled.

Case study: Using steel fiber precast refractories to extend cement kiln lining life

In a large state-owned cement group in China, the kiln inlet was originally protected using a combination of protective iron and castables, with a maximum service life of one year. The installation was cumbersome, requiring all remaining castables on site to be removed, the surface cleaned, and new castables poured.

After switching to steel-fiber prefabricated components, the process improved significantly. Since the steel-fiber components are pre-manufactured in the refractory material workshop, on-site installation is quick. This method eliminates the need for protective iron at the kiln inlet and does not require kiln firing. The prefabricated components can withstand rapid heating and frequent kiln stops, achieving a service life of up to 27 months.

Summary

Proper masonry, standardized casting processes, correct operating practices, and the selection of suitable refractory materials can effectively extend the service life of cement kiln linings. We hope this article has been helpful to you.

Jinheyuan Refractory Materials Co., Ltd. (JHYRef) provides high-quality refractory solutions for the cement industry. If you have any further questions, please feel free to contact us at any time.