Both fused cast zirconia-alumina bricks and sintered zirconia-alumina bricks take corundum (Al2O3) and zirconia (ZrO2) as their core components. However, due to differences in processes, they exhibit significant variations in performance and application.

I. Performance Differences

Density and Structure: Fused cast AZS bricks are formed by casting after electric melting at 1800-1900℃, with a corundum – zirconolite eutectoid structure inside, no obvious pores, high bulk density (≥3.8g/cm³), and low apparent porosity (≤2%). Sintered AZS bricks are densified through particle diffusion after sintering at 1700-1750℃, featuring slightly higher apparent porosity (3%-5%) and lower density (3.5-3.7g/cm³). However, they contain partially stabilized ZrO2, which tends to form microcracks.

Corrosion and Wear Resistance

The dense structure of fused cast AZS bricks can strongly resist the penetration of molten glass and metal slag, resulting in better corrosion resistance than sintered AZS bricks. Additionally, they have high surface hardness (Mohs hardness ≥9) and superior wear resistance. Due to microcracks and a small number of pores, sintered AZS bricks have slightly weaker resistance to liquid corrosion but better tolerance to gaseous media (such as high-temp flue gas).

Thermal Shock Resistance

The microcracks in sintered AZS bricks can buffer thermal stress, enabling them to withstand 10-15 cycles of water cooling at 1100℃ without cracking. Fused cast AZS bricks have a dense structure and high thermal expansion coefficient, leading to easy concentration of thermal stress and poor thermal shock stability (only 5-8 cycles of water cooling at 1100℃ under the same conditions).

Mechanical Strength

At room temp, fused cast AZS bricks have higher compressive strength (≥200MPa) and strong impact resistance. Sintered AZS bricks have a room-temp compressive strength of 150-180MPa, but their high-temp strength retention rate is more stable—above 600℃, their strength attenuation is 10%-15% less than that of fused cast AZS bricks.

II. Application Differences

Glass Industry

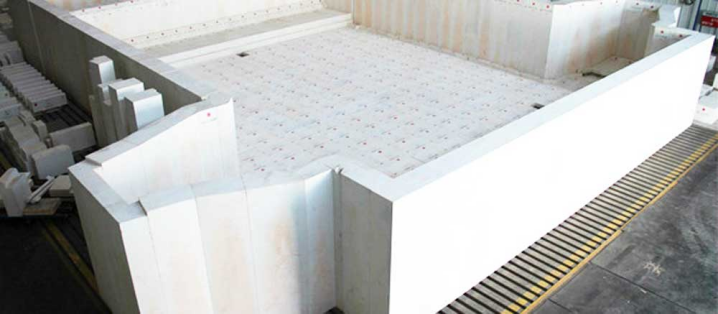

Fused cast AZS bricks are used in parts of glass kilns that come into contact with molten glass, such as the walls of glass melting tanks and throat channels (these parts directly contact molten glass and require strong corrosion resistance). Sintered AZS bricks are applied in high-temp areas of kilns that do not contact molten glass, including kiln crowns, checkerworks, and the outer sides of feeder channels (they need thermal shock resistance and flue gas corrosion resistance).

Metallurgical Industry

Fused cast AZS bricks are suitable for the linings of ladle refining furnaces and the iron tapping channels of blast furnaces (resisting corrosion from molten steel/slag). Sintered AZS bricks are used for the slide rails of steel rolling heating furnaces and the regenerators of hot blast stoves (requiring resistance to frequent heating and cooling, as well as flue gas scouring).

Other Fields

In the chemical industry, fused cast AZS bricks serve as linings for high-temp reactors (resisting corrosion from acid-alkali melts). Sintered AZS bricks are applied in the flue ducts of waste incinerators (with flue gas corrosion resistance and thermal shock resistance).

For working environments exposed to liquid corrosion and requiring high wear resistance, AZS fused cast bricks are selected. For non-contact high-temp environments that need thermal shock resistance, AZS sintered bricks are the choice.