In materials science, particularly in the field of refractory materials, chamotte (calcined clay) and fireclay (refractory clay) are two types of refractory raw materials that are closely related yet conceptually distinct. They have clear differences in terms of composition, processing technology, properties, and application scenarios.

Core Definitions and Essential Distinctions

| Item | Definition | Difference |

| Chamotte | The “pre-fired clinker” obtained by subjecting fireclay (refractory clay) to high-temperature calcination (typically 1,200–1,400 °C), followed by crushing and screening. | “Processed Product” (Secondary Raw Material) |

| Fireclay | A sedimentary rock that occurs naturally, is rich in clay minerals such as kaolinite, and possesses high-temperature stability (refractoriness ≥ 1,580 °C) as well as good plasticity. | “Natural Raw Material” (Primary Raw Material) |

To put it simply: Fireclay is a “raw material”, while chamotte is a “processed product” obtained by calcining fireclay at high temperatures—the two have a “raw material and product” relationship.Chamotte (also known as calcined fireclay) is created through the high-temperature calcination process, which transforms fireclay into a more stable, heat-resistant material. This is an important distinction, as chamotte is often used in the production of firebricks and other high-temperature resistant products.

Key Characteristics

| Items | Fireclay | Chamotte |

| Processing technology | After natural mining, it undergoes crushing and grinding (no high-temperature calcination required) | Using fireclay as raw material, it goes through high temperature calcination (to remove moisture / volatile components) → cooling → crushing → classification |

| Main Components | Kaolinite (Al₂O₃ · 2SiO₂ · 2H₂O), with small amounts of quartz and feldspar | After calcination, kaolinite is converted into mullite (3Al₂O₃ · 2SiO₂) and cristobalite, resulting in a more stable composition |

| Physical Properties | Contains crystalline water (about 14%)High plasticity at room temperature Prone to shrinkage at high temperatures | No crystalline water (moisture content ≤ 1%)No plasticity (hard texture)Excellent high temperature volume stability (extremely low shrinkage rate) |

| Refractoriness | 1580–1770 °C (increases with the rise of Al₂O₃ content) | 1600–1800 °C (more stable composition after calcination, with refractoriness slightly higher than that of the raw material) |

| Water Absorption | Relatively high (due to clay pores) | Relatively low (more dense pore structure after high temperature calcination) |

Typical Application Scenarios

Both types of materials are used in refractory manufacturing, however, due to differences in their properties, their application scenarios have distinct focuses.

Applications of Fireclay (Refractory Clay)

“Bonding Matrix” for Shaped Refractory Products: Leveraging its plasticity, it is mixed with chamotte and aggregates (e.g., waste refractory brick particles) to serve as a “binder” for refractory bricks and refractory castables. This enables the green body (unfired product) to be easily shaped during molding, and allows it to combine with aggregates at high temperatures to form a dense structure.

Low-Temperature Refractories: Used in the production of products with relatively low refractoriness requirements (below 1,600 °C), such as clay bricks for blast furnace hot stoves and refractory lining bricks for boilers.

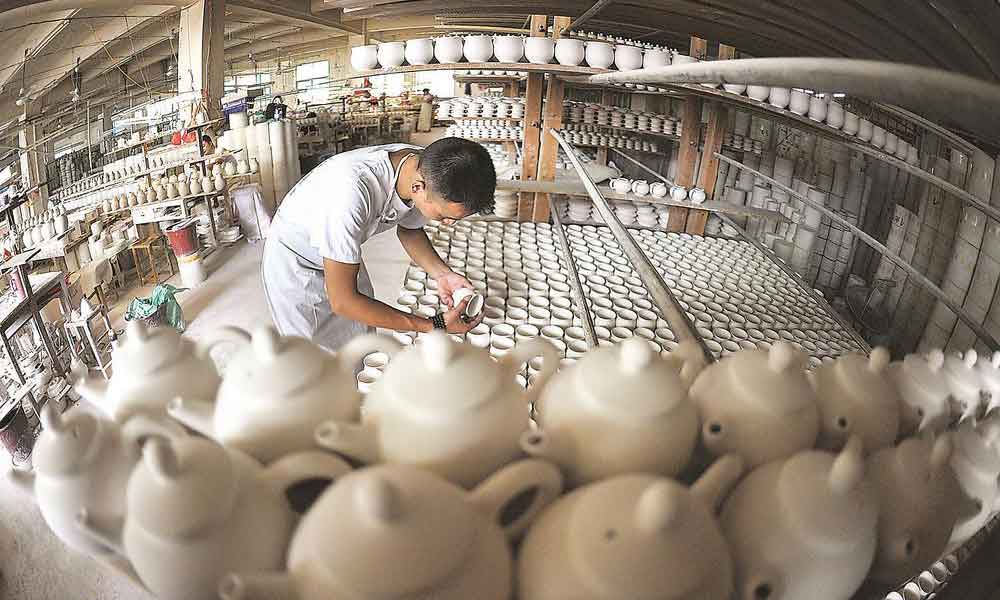

Ceramic Industry: Used in small quantities for manufacturing high-temperature-resistant ceramics (e.g., kiln furniture, insulating ceramics), utilizing its plasticity and sinterability.

Applications of Chamotte (Calcined Clay)

“Aggregate/Filler” for Refractories: As the main skeletal component of refractory bricks and refractory castables, it utilizes its high temperature volume stability to reduce shrinkage of products during sintering and prevent cracking.

Lining for High Temperature Industrial Kilns: Used in manufacturing refractory linings for high temperature kilns (e.g., ceramic kilns, glass kilns), or as “bottom-laying clinker” for kiln bottoms, resisting high-temperature scouring and erosion.

Lightweight Refractories: “Lightweight chamotte” (e.g., porous calcined clay) produced via special processes can be used in thermal insulation refractory products, achieving both high temperature resistance and thermal insulation performance.

Common Collocations and Precautions in the Industry

Combined Application: In actual production, the two are often mixed in a certain ratio (e.g., 20%–40% fireclay and 60%–80% chamotte). This combination not only utilizes the plasticity of fireclay to ensure formability but also improves the high-temperature stability of the product through chamotte.

Quality Indicators: The core indicators of fireclay are Al2O3 content (the higher the content, the stronger the refractoriness) and plasticity index (affects molding results).

The core indicators of chamotte are calcination temperature (must meet standards to ensure complete moisture removal) and particle gradation (matches the density requirements of different products).

Easily Confused Points: Both belong to “clay-based refractory raw materials,” but they are not interchangeable—directly replacing chamotte with fireclay will cause excessive high temperature shrinkage of the product, leading to cracking; replacing fireclay with chamotte will make molding impossible due to the lack of plasticity.

In summary, the core relationship between chamotte and fireclay is that of “raw material and processed product”. Their differences lie in processing technology, properties, and application roles. in refractory production, they usually work synergistically, jointly determining the quality of the final product.