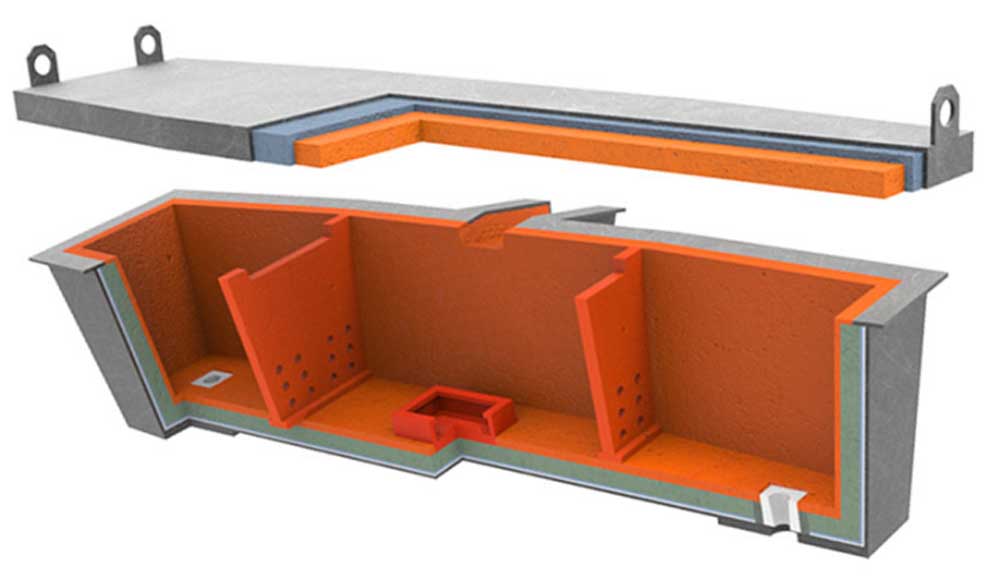

The lining of the tundish is composed of three parts: the insulation layer, the permanent layer, and the working layer. The working layer is in direct contact with the molten steel and is the basis for protecting the normal use of the tundish.

The continuous casting tundish uses a dry refractory material working layer, which has the advantages of no pollution to the molten steel, long service life, simple process, convenient maintenance, easy to turn over and clean the tundish, and high operating efficiency. Therefore, the dry refractory material working layer is widely used in the continuous casting tundish.

The currently popular dry refractory materials are mainly basic magnesia dry materials, which are vibrated and baked by the working lining membrane to form a hard and flat working layer. The smoother the working layer is, the more effectively it can resist erosion, scouring and penetration of molten steel and steel slag.

However, the tundish often collapses during online use. With a monthly output of 400,000 tons of molten steel, the tundish collapse accidents reached 18 to 20 times, with an accident rate of more than 0.45 times/10,000 tons of steel.

We analyzed the causes of tundish collapse and took measures such as refining construction, adjusting dry materials, optimizing the tundish baking system, and developing and applying a permanent layer knotting device to prevent tundish collapse. The tundish collapse accident rate was reduced to less than 0.05 times per 10,000 tons of steel, providing favorable guarantees for the safe use of tundishes and high-efficiency continuous casting production.

Dry material belongs to resin-bonded magnesia refractory, and the amount of resin added is about 3%. The physical and chemical reactions of the dry material during the heating process are mainly the resin and the reaction or change caused by the resin.

When the temperature is raised below 60 ℃, the plasticity of the resin increases, which is suitable for filling molding. 60~150 ℃ belongs to the stage of resin polymerization and curing. The products of resin polymerization reaction include water and low molecular volatiles such as phenol and formaldehyde. 200~300 ℃ belongs to the stage of free water elimination and drying. 350~600 ℃ is called the low temperature stage, at which time the resin begins to oxidize and decompose. It is also the stage of magnesia raw material combined with water elimination.

The easy oxidation of resin is the main reason why the baking time on the tundish cannot be too long. 800~1000 ℃ is called the medium temperature stage, which belongs to the resin carbonization stage, that is, the resin is thermally polymerized at room temperature and transformed into resin carbonization. The sintering effect of dry material in the medium temperature stage is not significant, and the strength of the working layer is reduced to the minimum at this time. The main reason for the collapse of the tundish is that the medium fire time is short and the high fire time is long.