What is Aluminum Phosphate Wear-Resistant Brick?

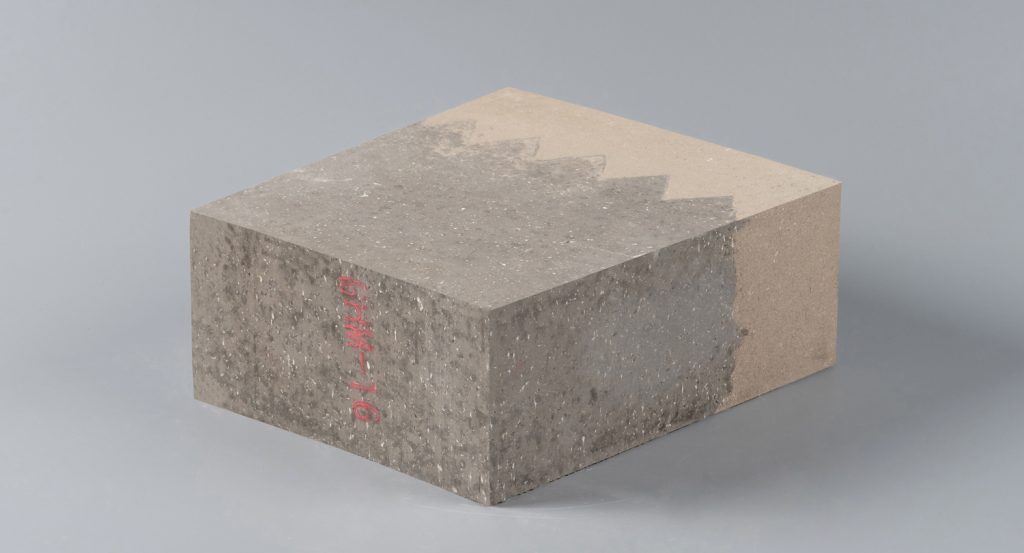

Aluminum phosphate wear-resistant bricks are high-performance refractory and wear-resistant products made from refractory aggregates like high-alumina bauxite and corundum, with phosphate or aluminum phosphate solution as the binder.

These bricks are produced through a special process and are also known as phosphate-bonded wear-resistant bricks.

Core Advantages of Aluminum Phosphate Wear-Resistant Bricks

The core advantages of aluminum phosphate wear-resistant bricks stem from the chemical bonding reaction between the phosphate and aggregates, which forms a dense and stable structure. This results in excellent wear resistance, high-temperature resistance, and thermal shock resistance.

Final Structure of Phosphate Refractory Materials

The final structure of phosphate-bonded refractory materials evolves progressively with increasing temperature, ultimately forming a dense structure of “aggregate framework + ceramic bonding phase.”

| Temperature Range | Structure | Strength Source |

| Room Temp – 100°C | Loose structure: • Aggregate particles wrapped by phosphoric acid/phosphate gel • Gel not fully solidified • Numerous micropores present | Chemical products from the reaction between phosphoric acid and aluminum oxide |

| 100 – 600°C | Initial densification: • Gel dehydrates and polymerizes • Forms aluminum phosphate (AlPO₄) crystals • Partially fills micropores • Aggregates and binder initially bond together | Transformation of chemical products |

| 1200+°C | Ceramic bonding stage: • Fine powder in matrix begins slow sintering • Sintering intensifies as temperature increases • Material becomes denser | Sintering-induced |

Final High-Temperature Structure: Refractory aggregates (such as corundum and high-alumina particles) serve as the “skeleton,” while the continuous ceramic bonding phase (AlPO₄, Al₂O₃-AlPO₄ solid solution) fills the gaps between the skeleton. This forms a densely interwoven “skeleton-bonding phase” structure that combines high-temperature strength and corrosion resistance.

Production Process to Ensure High-Performance Aluminum Phosphate Wear-Resistant Bricks

The production process requires precise control of each step to ensure stable performance.

Raw Material Preparation

The aggregates used include high-alumina clinker and corundum that have been calcined at temperatures above 1600°C. Fine powders of high-alumina and corundum are added to enhance the brick’s density.

Binder Selection

Phosphoric acid solution or aluminum dihydrogen phosphate solution is used as the binder. The components are mixed in proportion, and after mixing, the mixture needs to be left to rest for more than 24 hours.

Molding Process

A high-pressure machine with a capacity of over 600 tons is used to press the mixture into shape, ensuring the bricks are dense. The typical bulk density is greater than 2.5.

Drying Process

The bricks are dried at temperatures between 100°C and 200°C for several hours to remove excess moisture.

Conclusion

Need high-performance aluminum phosphate abrasion-resistant bricks? Contact JHYRef experts now for customized recommendations.

FAQ – Frequently Asked Questions

1. What is Aluminum Phosphate Abrasion-Resistant Brick?

Aluminum phosphate abrasion-resistant brick is an unfired refractory brick made from high-alumina bauxite or corundum as aggregate, bonded with aluminum phosphate solution, and processed through molding and low-temperature baking. It features excellent wear resistance, thermal shock resistance, and high-temperature performance, widely used in severely worn areas such as cement kiln inlets, circulating fluidized bed boilers, and coke ovens.

2. What’s the difference between this and ordinary high-alumina bricks?

Ordinary high-alumina bricks require firing at over 1500°C with high energy consumption. Aluminum phosphate-bonded bricks only need baking at 500-600°C, offering higher strength, better densification, superior wear resistance, faster construction, and lower costs—making them an energy-efficient alternative to fired bricks.

3. Why is it called “aluminum phosphate bonding”? What does it do?

Aluminum phosphate (AlPO₄) forms a ceramic-like bonding network when heated, acting like “cement” to firmly bind refractory aggregates together. This creates a dense, hard, erosion-resistant structure—the core source of its wear resistance.

4. Can this brick be used in cement kiln inlets?

Absolutely! It’s the preferred material for cement kiln inlets, coal injection pipes, and tertiary air ducts. It resists high-temperature material erosion and alkaline gas corrosion, with a service life 50% longer than ordinary bricks.

5. Does aluminum phosphate brick require high-temperature firing?

No firing needed! It’s an “unfired brick.” After molding, it only requires drying (100-120°C) + low-temperature heat treatment (500-600°C, holding for 4-8 hours) to achieve high strength—energy-saving, time-efficient, and environmentally friendly.

6. Is it wear-resistant? How long does it last?

Extremely wear-resistant! In CFB boilers or cement kilns, the wear rate is below 2.5%, with a normal service life of 1-3 years—far exceeding ordinary clay bricks and some high-alumina bricks.

7. What happens if used without baking?

It will pulverize! Unbaked bricks have incompletely crystallized aluminum phosphate, which will absorb moisture or soften at high temperatures, causing a sharp drop in strength. Proper baking to above 550°C is essential for stable use.