Generally, the blast furnace tapping channel (main channel) is a channel that guides high-temperature molten iron and slag and fully separates them. It works in a long-term periodic flushing environment of high-temperature molten iron and slag.

Because it is subjected to chemical erosion and penetration from high temperature molten iron and slag at the same time, as well as temperature changes caused by intermittent iron tapping, or inadequate monitoring, it is easy for the iron groove to burn through and leak iron.

Especially in the area of the main ditch where the iron falls, it is more susceptible to erosion. Once the iron ditch is burned through, the molten iron will leak to the furnace platform or even under the iron-casting platform, which may cause a major safety accident and produce a series of adverse effects.

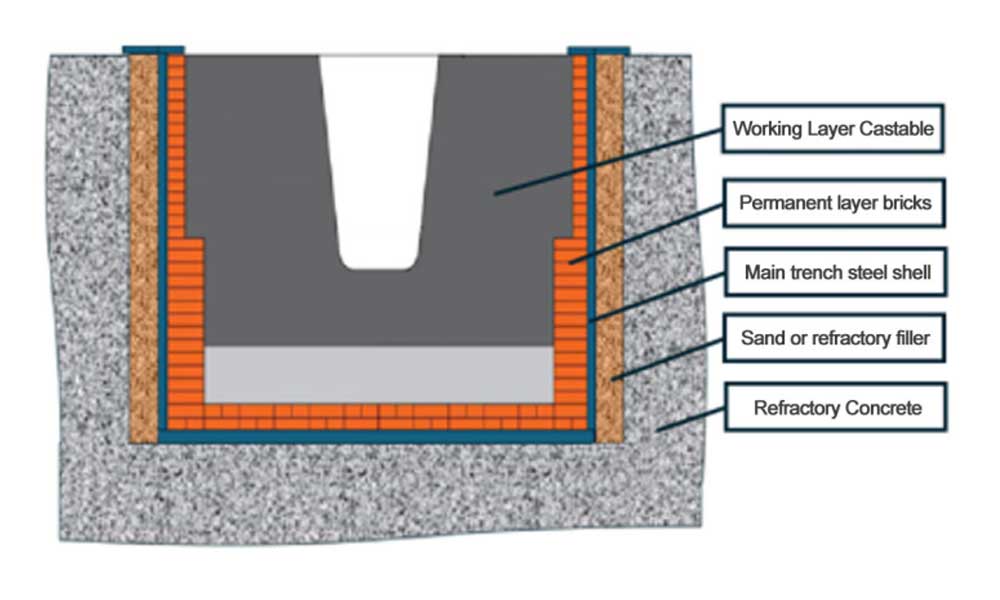

At present, yellow sand or refractory filler is filled between the steel shell of the main trench of the conventional blast furnace and the refractory concrete. The permanent layer inside the steel shell is built with refractory bricks, and finally the main trench working layer castable is poured. The main trench steel shell of this structure is buried in yellow sand and refractory materials, and the heat of the steel shell cannot be dissipated. As the main trench working layer erodes, the temperature of the steel shell will continue to rise. When the thickness of the working layer reaches about 200mm, the temperature of the iron trench steel shell will reach above 700℃.

High temperature will cause the steel shell to expand and deform, and the deformation will continue to increase with the working time, and eventually the weld will crack. The steel shell loses its restraint and support function on the refractory material, which will cause the trench lining to crack. This is also the reason why the steel shell of the conventional main trench generally needs to be replaced every 3-5 years. During these 3-5 years, the amount of materials used for periodic maintenance of the main trench continues to increase, but the periodic life continues to decrease, and the risk of iron leakage also increases year by year.

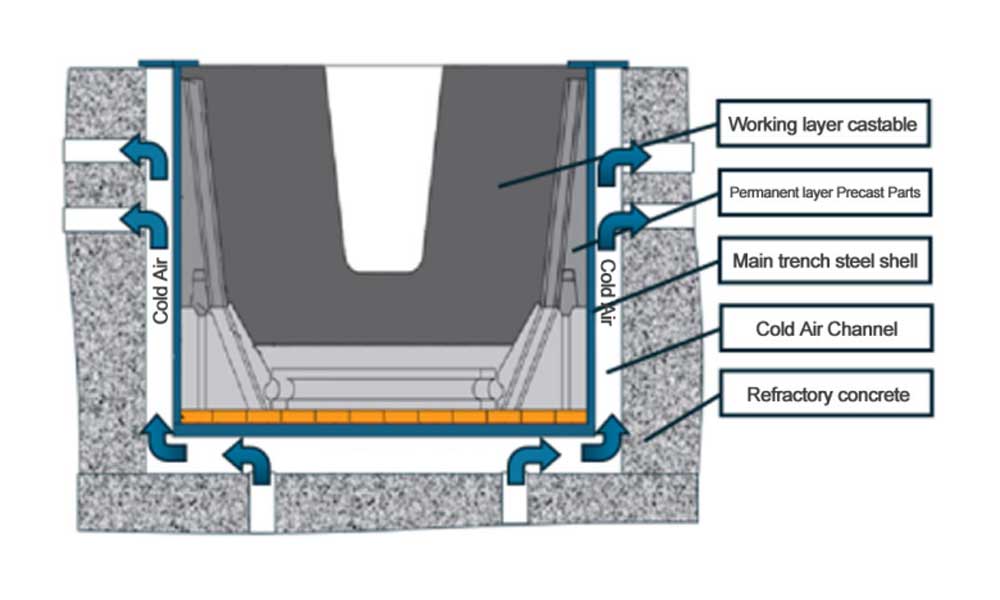

According to the above situation, the steel shell air cooling technology is adopted to improve the safety and life of the iron ditch. The measures taken by this technology are: leaving a cavity between the main ditch steel shell and the refractory concrete as an air cooling channel, and opening ventilation holes on the bottom and wall of the ditch. A layer of 10mm thick nano insulation board is pasted inside the steel shell, and the permanent layer is assembled with high-strength large prefabricated blocks, and finally the main ditch working layer is poured.

During the operation of the main trench, the heat of the steel shell of the main trench is removed by blowing air to achieve a cooling effect. By adopting this air cooling technology, even if the residual thickness of the erosion of the working layer of the main trench drops to about 100mm, the temperature of the steel shell remains below 350℃.

Since the steel shell is always at a relatively low temperature, it will not deform or crack, and the service life of the main trench can reach more than 10 years. Since the steel shell always keeps the restraint and support on the trench lining, the cracking of the main trench is greatly reduced, which greatly reduces the maintenance cost.